News

Research Summary Report of A02

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [06.10.2023] Hamilton, Leigh Duncan; Researcher; Leigh-Duncan.Hamilton@tu-braunschweig.de Zetzener, Harald; Leading researcher H.Zetzener@tu-braunschweig.de Kwade, Arno; Project leader A.Kwade@tu-braunschweig.de All: TU Braunschweig, Institute for Particle Technology Our main goal within project A02 is to unite two additive manufacturing (AM) processes, thereby, creating a hybrid AM process for structural concrete. The foundation of A02 is formed around the concrete 3D printing process Selective Paste Intrusion (SPI). SPI creates components in layers by first spreading coarse aggregates (usually quartz) on a surface or previous layer. Subsequently, the cement slurry is applied onto designated areas, where it fills void volumes between aggregate particles. The second …

Research Summary Report of A05

Category: Research Summary Report

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete [29.09.2023] Rothe, Tom; Doctoral researcher, t.rothe@tu-braunschweig.de, TU Braunschweig, Institute of Mechanics and Adaptronics (IMA) Hühne, Christian; Project Leader, Christian.Huehne@tu-braunschweig.de, TU Braunschweig, Institute of Mechanics and Adaptronics (IMA) Fig 2: Robotic integration of reinforcement into the column of the Shelltonics demonstrator The individual integration of fibre reinforcement into large concrete components produced by Additive Manufacturing allows new design freedoms and reduces concrete consumption due to reduced concrete cover. The project A05 develops strategies to integrate freely formable reinforcement strands for the different AM processes. For doing so, a Dynamic Winding Machine is developed and constantly updated. This machine is used to consolidate and impregnate a primary fibre strand …

Research Summary Report of A04

Category: Research Summary Report

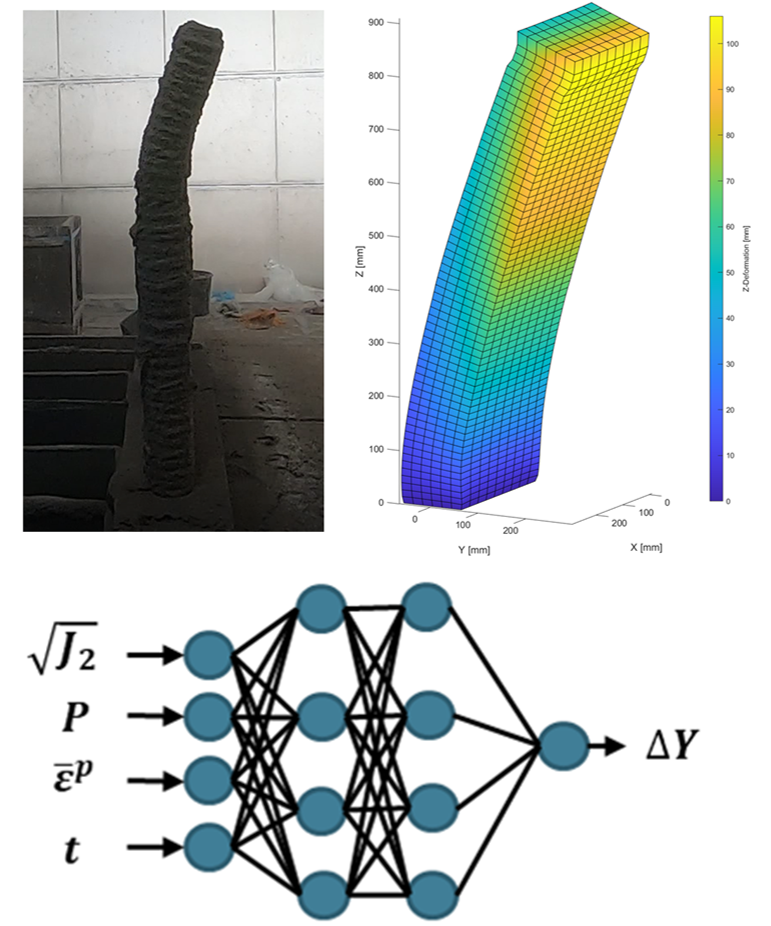

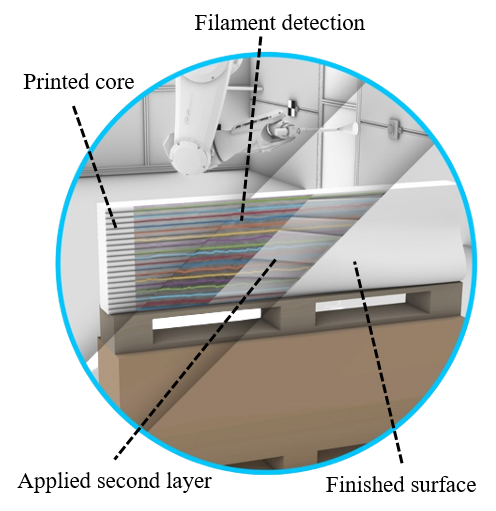

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [30.09.2023] David, Martin; Doctoral Researcher, m.david@tu-braunschweig.de, TU Braunschweig, Institute for Machine Tools and Production Technology (IWF) Summary and Current state of research Project A04 aims to investigate cooperative Additive Manufacturing (AM) processes based on Shotcrete 3D Printing (SC3DP) for the production of material-efficient, force-optimised, reinforced, load-bearing concrete components with precise surface quality and geometrical precision. The goal is to produce large-scale concrete elements using significantly lower amounts of reinforcement and concrete as compared to standard concrete construction principles. Hereby, different robot guided end effectors are subject to research in a flexible and automated process chain. Currently, the following key points are researched by the …

Research Summary Report of A06

Category: Research Summary Report

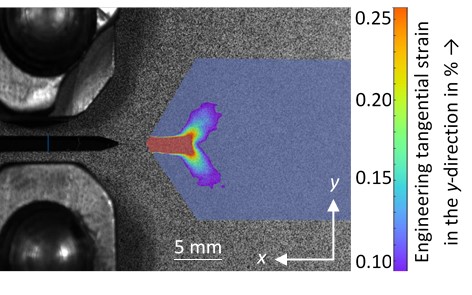

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience [22.09.2023] Wenzler, David; doctoral researcher; david.wenzler@tum.de Technical University of Munich, Institute for Machine Tools and Industrial Management Diller, Johannes; doctoral researcher; johannes.diller@tum.de, Siebert, Dorina; doctoral researcher; dorina.siebert@tum.de Technical University of Munich, Chair of Metal Structures Project The project A06 aims to explore and evaluate the factors influencing the manufacturing of safe and durable structural steel elements by laser powder-bed fusion (LPBF). Thereby, the LPBF process, the post-treatment, and the influence of the part geometry on the microstructure and the mechanical properties will be investigated. From the results, correlations between these aspects will be determined. In the 1st funding period, the project focuses on …

The Collaborative Research Center TRR 277 pioneers the Future of Construction with 3D Printing

The Collaborative Research Center TRR 277 AMC is excited to announce its upcoming event, the First Funding Period Closing Conference, scheduled to take place from October 9th to 11th, 2023. The conference, held at TU Braunschweig’s Audimax, showcases the remarkable research outcomes from the initial four years of the DFG-funded Transregio project, featuring a keynote speech by Achim Menges. TRR 277 AMC’s research is centered around the future of Digital Building, emphasizing resource-efficient and energy-efficient construction methods enabled by 3D printing technology. This innovative approach not only redefines traditional construction practices but also offers new design freedoms by integrating material, process, and design considerations. Presenting a comprehensive overview of the research accomplishments, the AMC Conference provides an exceptional opportunity for …

Research Summary Report of A07

Category: Research Summary Report

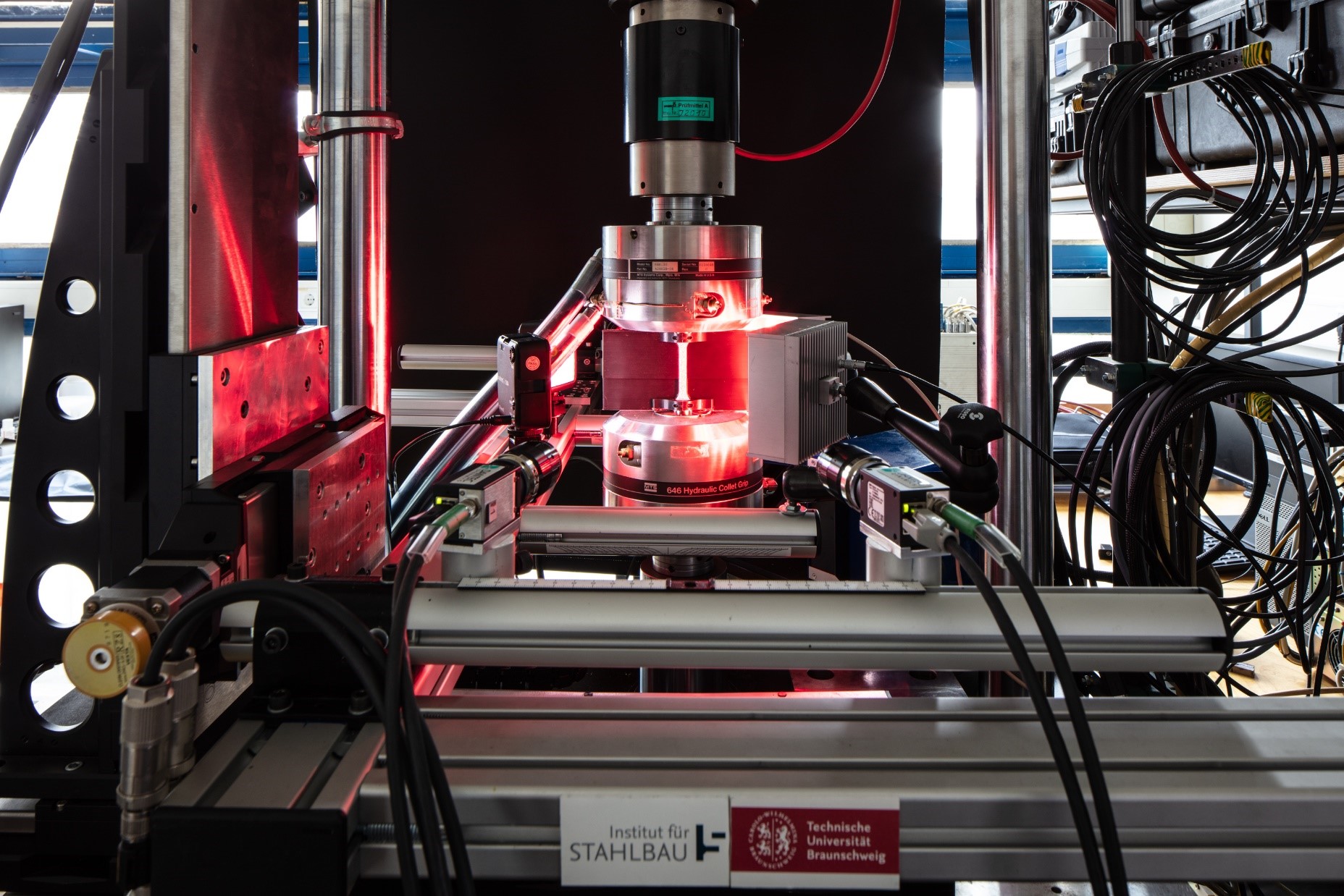

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components [08.09.2023] Jahns, Hendrik; Doctoral researcher; h.jahns@stahlbau.tu-braunschweig.de Unglaub, Julian; Principle Investigator j.unglaub@stahlbau.tu-braunschweig.de Thiele, Klaus; Principle Investigator k.thiele@stahlbau.tu-braunschweig.de Institute of Steel Structures Technische Universität Braunschweig Project – main goal In project A07 the design, manufacturing and mechanical properties of complex individualized WAAM steel nodes for use in construction is investigated. A new method is developed to design force flow optimized steel nodes as connectors between semi-finished parts and anchorage structures considering the manufacturing possibilities of the WAAM-process and the resulting material behavior. The manufacturing possibilities will be identified by case study demonstrators, which represent occurring features of the designed node. The produced parts are characterized regarding their mechanical properties. …

Research Summary Report of A08

Category: Research Summary Report

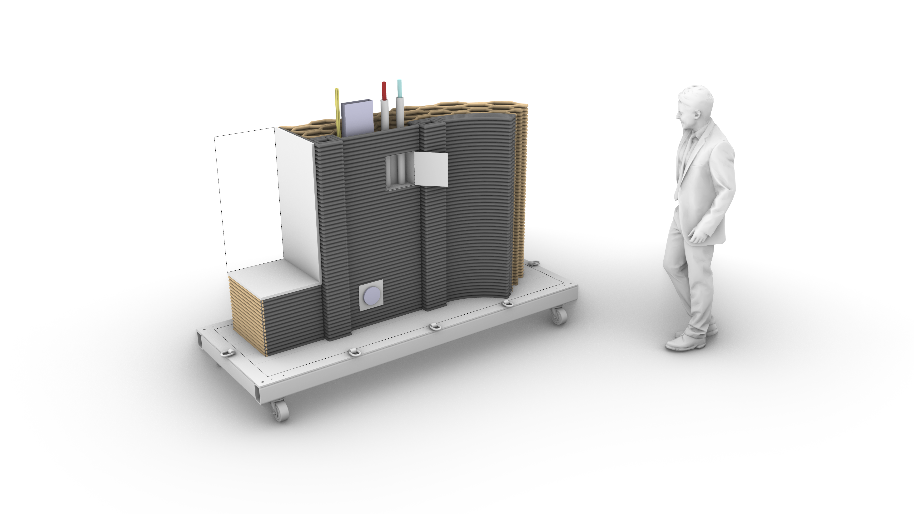

Structural Timber by Individual Layer Fabrication (ILF) [01.09.2023] Asshoff, Carsten; Doctoral researcher; carsten.asshoff@wki.fraunhofer.de Fraunhofer Institute for Wood Research Wilhelm-Klauditz-Institut WKI Main goal The main goal of the project ’A08 – Structural Timber by Individual Layer Fabrication (ILF)’ is to develop a process to additively manufacture large-scale, wood composite objects with a maximum content of wood material and strength values suited for applications in construction. In the course of the project multiple process variants and material combinations are explored. For this, the necessary machinery is developed in iterative steps and the mechanical properties of the resulting objects as well as the geometric capacity of the processes are investigated. Finally, multiple demonstrators are fabricated for showcase purposes. Summary Working …

AMC Conference 9./10./11. October 2023

Join us now! AMC Conference with a Keynote by Achim Menges Start: 1:30 PM (10th Ocotber 2023) With the following access data you can join the web broadcast: Zoom Meeting https://us02web.zoom.us/j/86763005356?pwd=aGlhWVhoM0s0R3dLTEhONUh2QzF5dz09 Meeting-ID: 867 6300 5356 Kenncode: TRR277-AMC Meeting-ID: 867 6300 5356 Kenncode: TRR277-AMC You can also download the detailed programme from our website: https://lnkd.in/ex6v_PkU The Collaborative Research Center TRR 277 AMC is excited to announce its upcoming event, the First Funding Period Closing Conference, taking place on October 9th – 11th, 2023. Set within the TU Braunschweig’s Audimax, the conference will showcase the remarkable research highlights achieved during the initial four years of the Transregio. Presenting a comprehensive overview of our research accomplishments, the event provides an opportunity for a …

Research Summary Report of B04

Category: Research Summary Report

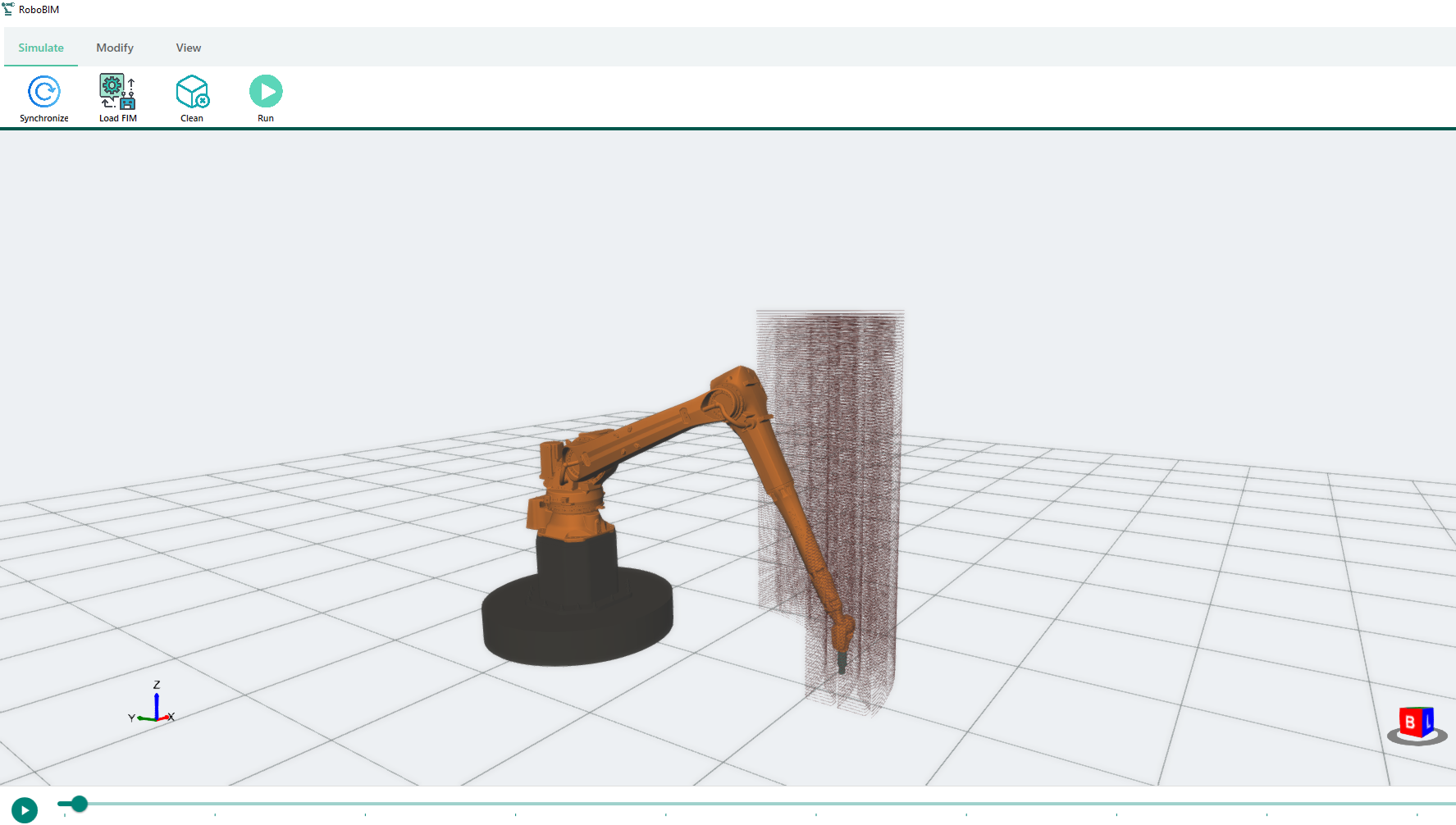

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom [26.08.2023] Ekanayaka, Virama; Doctoral researcher, v.ekanayaka@tu-braunschweig.de, TU Braunschweig, Institute of Machine Tools and Production Technology (IWF) Hürkamp, André; Project Leader, a.huerkamp@tu-braunschweig.de, TU Braunschweig, Institute of Machine Tools and Production Technology (IWF) Main goal The integration of robot-guided additive manufacturing in the construction industry increases the degree of automation and can thus lead to an increased productivity and increased component quality. In shotcrete 3D printing (SC3DP), reproducible manufacturing results and ensuring component quality are major challenges, as the properties of shotcrete depend on many different parameters (e.g. temperature, pressure, water-cement ratio, hardening accelerator). The goal of this research project is …

Research Summary Report of C03

Category: Research Summary Report

Integration of Passive and Active Functions in Additively Manufactured Construction Elements [25.08.2023] Auer, Thomas; PL, thomas.auer@tum.de * Briels, David; doctoral researcher, david.briels@tum.de * Nouman, Ahmad; doctoral researcher, ahmad.nouman@tum.de * all: Technical University of Munich, TUM School of Engineering and Design, Chair of Building Technology and Climate Responsive Design Main goal To fully leverage the potential of additive manufacturing (AM) processes explored within the AMC, a fundamental shift in the design of building elements is necessary. Through the capabilities of AM, we can create highly specialized components that seamlessly integrate and enhance both passive and active functions, encompassing building physics (such as heat transfer and acoustics) and building services (including heating, cooling, and ventilation). Our overarching goal is to achieve …

Research Summary Report of C06

Category: Research Summary Report

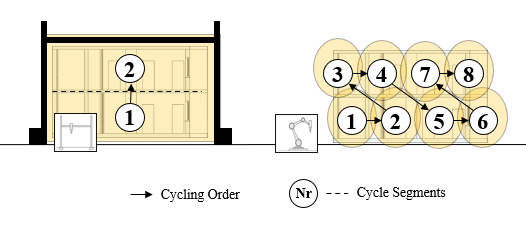

Integration of Additive Manufacturing in the Construction Process [18.08.2023] Mawas, Karam; Doctoral researcher, k.mawas@tu-braunschweig.de Gerke, Markus; Project leader, m.gerke@tu-braunschweig.de Maboudi, Mehdi; Associated scientist, m.maboudi@tu-braunschweig.de all: TU Braunschweig, Institute of Geodesy and Photogrammetry (IGP) Main goal To guarantee adherence to a resilient process and faithful realization of the designed model in the printed object, it is essential to implement ongoing and automated data capture and process inspection. Additionally, quality control plays a pivotal role in enabling the seamless integration of components into objects. Summary An essential phase within 3D printing is quality assurance. Incorporating automated quality control into the production cycle can significantly augment productivity. With the rapid construction capabilities offered by 3D concrete printing (3DCP), upholding stringent quality standards …

Research Summary Report of A03

Category: Research Summary Report

Extrusion of Near-Nozzle Mixed Concrete – Individually Graded in Density and in Rate of 3D Fibre Reinforcement [06.08.2023] M.Sc. Dahlenburg, Maximilian; TP editor, maximilian.dahleburg@tum.de, TUM, Chair of Materials Handling, Material Flow, Logistics Prof. Dr.-Ing. Fottner, Johannes; Project leader, j.fottner@tum.de, TUM, Chair of Materials Handling, Material Flow, Logistics Main Goal The main goal of A03 is to establish a novel concrete extrusion process using a near nozzle mixing (NNM) process to enable the change and non-discrete gradation of material and its properties during printing. With this approach, multi-functional and multi-material parts can be printed, with an overall higher building rate due to a lower workability demand of the process and higher structuration rates of the used materials. Printed parts can thus simultaneously fulfil load-bearing …

Research Summary Report of A01

Category: Research Summary Report

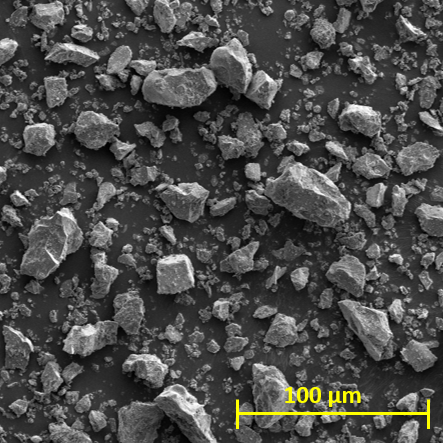

Particle-bed 3D printing by selective cement activation: Particle surface functionalization, particle bed compaction and reinforcement [21.07.2023] Meier, Niklas; Researcher, niklas.meier@tu-braunschweig.de Zetzener, Harald; Leading researcher, h.zetzener@tu-braunschweig.de Kwade, Arno; Project Leader, a.kwade@tu-braunschweig.de all: TU Braunschweig, Institute for particle technology The main goal of our research in project A01 is to improve the mechanical strength and shape accuracy of the printed concrete parts as well as the printing speed. While our work at the iPAT is improving the powder properties the project partner iBMB focuses on the material-process interaction. Summary Previous research has shown, that a higher packing density of the particle bed leads to an increase in compressive strength. On the one side the process parameter during printing e.g. compaction heigt …

Research Summary Report of C04

Category: Research Summary Report

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods [14.07.2023] Li, Chao; doctoral researcher, chao1.li@tum.de Petzold, Frank; PL, petzold@tum.de Technical University of Munich, TUM School of Engineering and Design, Chair of Architectural Informatics The application of Additive Manufacturing (AM) technology requires careful consideration of AM methods‘ boundary conditions. Determining suitable AM methods is critical during the early design stages since changes in design are costly when design becomes more mature. To this end, WP1 of sub-project C04 aims to develop a design decision support system (DDSS) that assists architects and engineers in choosing feasible AM methods for BIM-based design. To achieve this, a knowledge base is formalized, which consists of information on different AM …

Research Summary Report of A04

Category: Research Summary Report

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [07.07.2023] Rudolph, Jennifer; doctoral researcher, j.rudolph@ibmb.tu-bs.de Freund, Niklas; doctoral researcher, n.freund@ibmb.tu-bs.de Lowke, Dirk; project leader, d.lowke@ibmb.tu-bs.de all: TU Braunschweig, Institute of Building Materials and Concrete Construction and Fire Safety (iBMB) Summary Project A04 investigates cooperative Additive Manufacturing (AM) processes based on Shotcrete 3D Printing (SC3DP) for the production of material-efficient, force-optimised, reinforced, load-bearing concrete components with precise surface quality and high geometric precision. The goal is to produce large-scale concrete elements using significantly lower amounts of reinforcement and concrete as compared to standard concrete construction principles. Current state of research Reinforcement integration is one of the key topics of current research in the field …

Research Summary Report of C06

Category: Research Summary Report

Integration of Additive Manufacturing in the Construction Process [16.06.2023] Placzek, Gerrit; Doctoral researcher, g.placzek@tu-braunschweig.de, TU Braunschweig, IBB The integration of additive manufacturing into construction requires an interdisciplinary approach. The different competences of the team – digital fabrication in architecture (Hack), geodesy and photogrammetry (Gerke) and construction management (Schwerdtner) – lead to research from diverse perspectives on the various scalar levels of construction to be viewed holistically: component, building and industry scale. Within Subproject C06, our goal is to create a continuous digital and lean-based process chain from design (using BIM method) to fabrication (using AM method). Based on process models und strategic decisions, we investigate construction processes and how to change them into a construction industry 4.0. Summary In …

Research Summary Report of C05

Category: Research Summary Report

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes [19.05.2023] Empelmann, Martin; Project Leader, m.empelmann@ibmb.tu-bs.de Lanwer, Jan-Paul; Doctoral Researcher, j.lanwer@ibmb.tu-bs.de TU Braunschweig, Institute of Building Materials, Concrete Construction and Fire Safety (iBMB), Division of Concrete Construction The C05 project deals with the design, the manufacturing and the calculation of suitable connections for segmental AM-components. Principally, the connections should be based on the dry joint approach manufactured by subtractive post-processing. Alternatively, they could be also directly printed with the segment. The joint design should be efficient in production, apply for all AM-processes (SC3DP, Extrusion, Particle bed) and bear combined normal and shear stresses. Summary The selected joint profiles from the so-called joint catalogue (see Reference) …

Research Summary Report of A08

Category: Research Summary Report

Structural Timber by Individual Layer Fabrication (ILF) [09.06.2023] Buschmann, Birger; Doctoral researcher, birger.buschmann@tum.de, Talke, Daniel; Doctoral researcher, talke@tum.de Henke, Klaudius; Project leader, henke@tum.de Technical University of Munich, Chair of Timber Structures and Building Construction Summary The main goal of the project ‘A08 -Structural Timber by Individual Layer Fabrication (ILF)’ is to develop a process to additively manufacture large-scale, wood composite objects with a maximum content of wood material and strength values suited for applications in construction. In the course of the project multiple process variants and material combinations are explored. For this, the necessary machinery is developed in iterative steps and the mechanical properties of the resulting objects as well as the geometric capacity of the processes are investigated. Finally, …

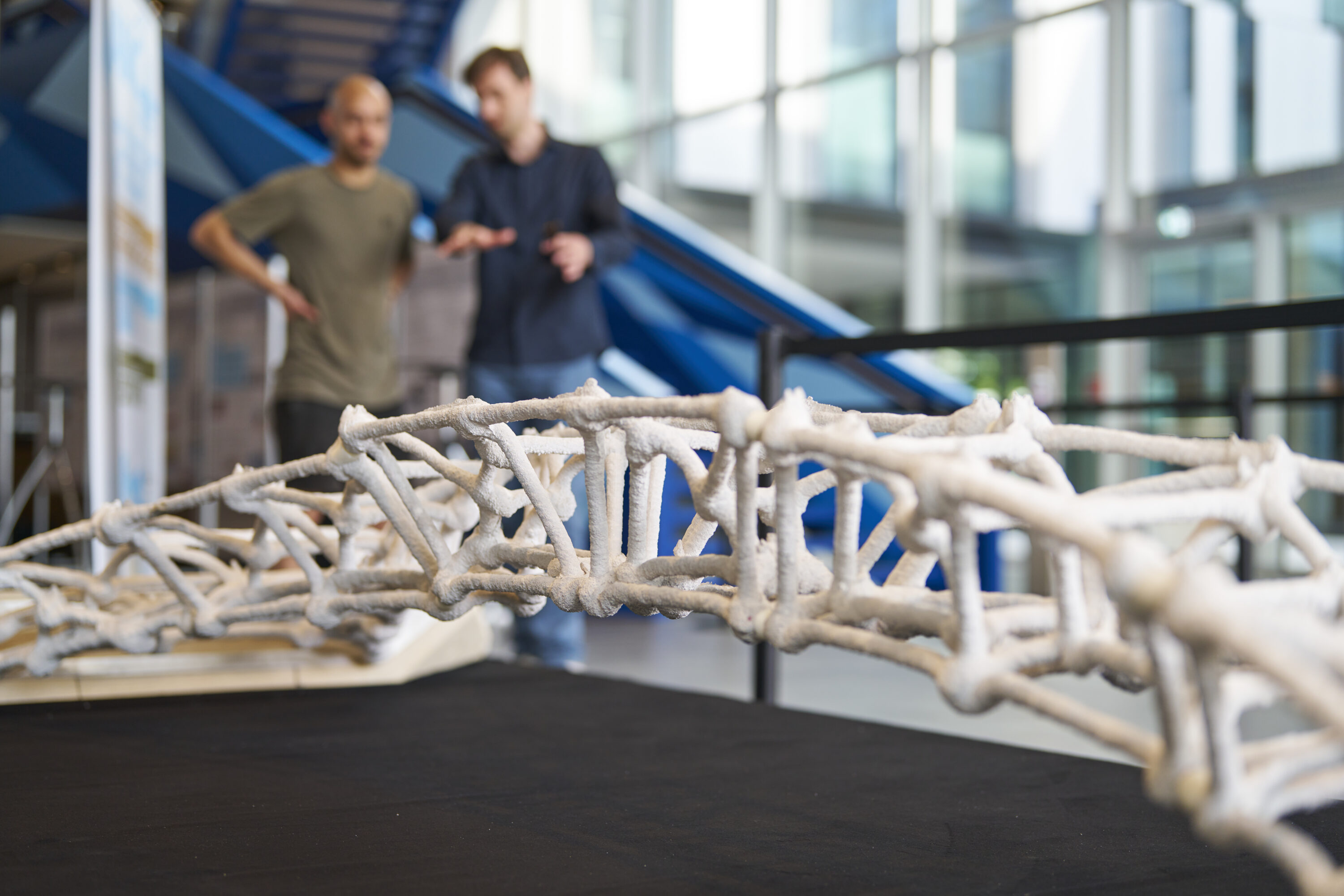

AMC präsentiert Forschungsergebnisse / AMC presents research results

Sonderforschungsbereich AMC präsentiert Forschungsergebnisse Bei strahlendem Sonnenschein fand letzte Woche die Begutachtung des Sonderforschungsbereichs Transregio 277 Additive Manufacturing in Construction (AMC) im Forschungszentrum München/Garching statt. Mit großer Freude präsentierten wir unsere „Collaborative Demonstrators“ und stellten die Ergebnisse unserer intensiven Forschungen aus der ersten Förderperiode vor. Unser herzlicher Dank geht an die Deutsche Forschungsgemeinschaft (DFG) für die Förderung und die Unterstützung. Ebenso möchten wir unseren aufrichtigen Dank an das gesamte AMC-Team mit seinen Wissenschaftler*innen, Techniker*innen, Mitarbeiter*innen sowie Hilfskräften und natürlich auch an die Hochschulleitungen der TU Braunschweig und TU München aussprechen, die alle mit viel Engagement daran gearbeitet haben, den AMC und seine Forschungen bestmöglich zu präsentieren. Der TRR 277 AMC ist nicht nur ein Ort wegweisender Forschung, sondern vor allem …

LABDay at the Collaborative Research Centre AMC

LABDay at the Collaborative Research Centre AMC What possibilities does 3D printing offer for architecture and for the entire construction industry? What can this new technology do and how can it be used creatively? The AMC LABDay was initiated to get to the bottom of these questions with school students. In this one-day workshop, pupils learn details about the digital fabrication process from design to production. The special feature: the school students can digitally design an object themselves and this object is then printed on site by a robot. The first workshop was already a great success. The participants were able to directly participate in creative design, augmented reality, software and robotic 3D printing production. Find out more about the …