Project C 03

Networking with other projects

Poster

TRR277_C03_Poster_01-DFG-Begutachtung (2)

TRR277_C03_Poster_02-DFG-Begutachtung (2)

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

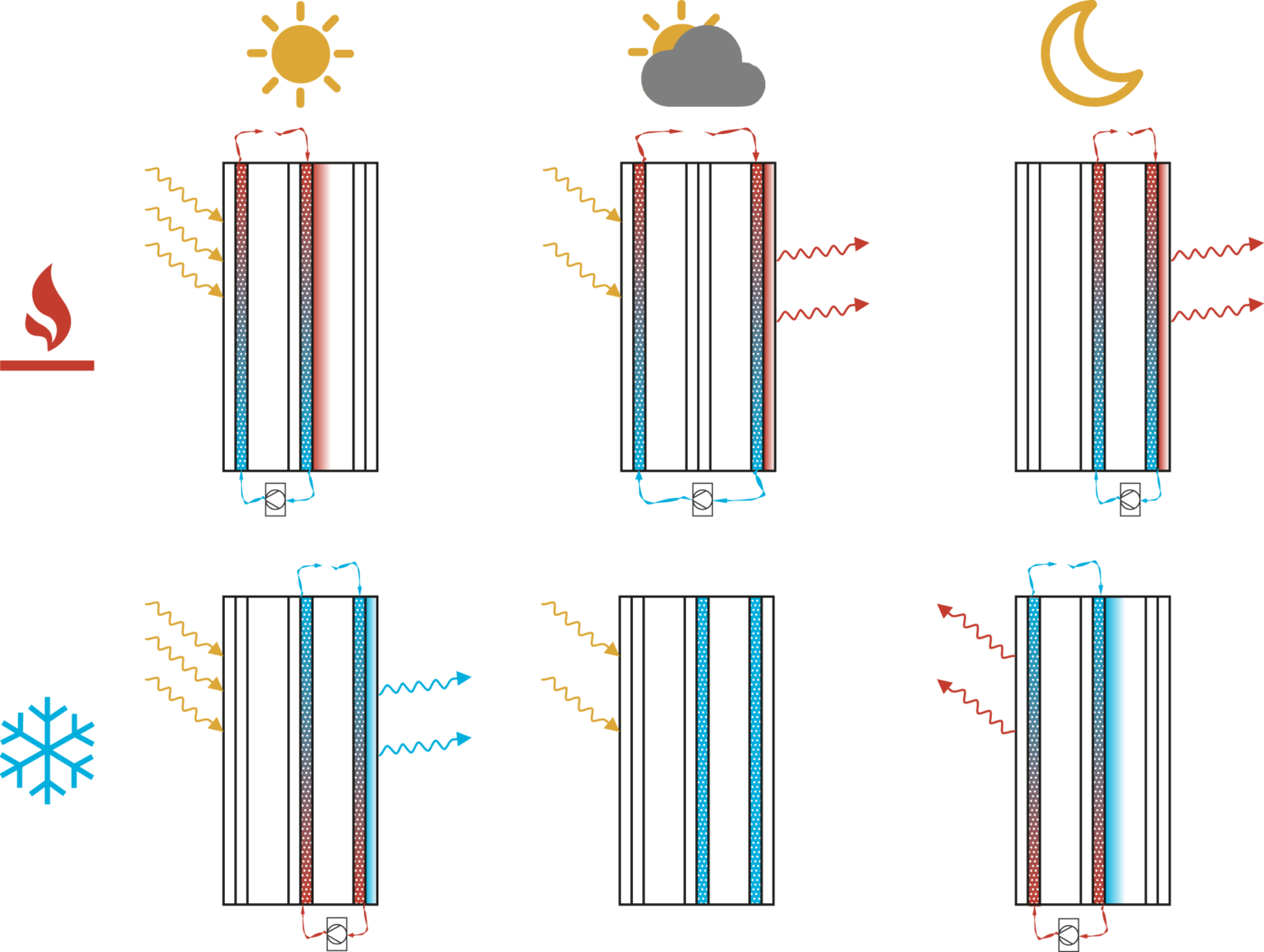

This project aims to develop and test additively manufactured building components that integrate multiple passive and active functions to improve building operation and environmental quality. The performative features are directly incorporated into building components to fully exploit the potential of AM. Thus, recyclability and performance are enhanced by shifting the approach from complex multi-layered and multi-material to mono-material and multi-functional components. These components are developed and optimized through a simulation-based parametric design process for integrated performative functions. Thereby, this research aims for high robustness through functional integration in the design and fabrication process and intends to improve building performance.

Objective

The primary objective is to identify passive and active strategies to integrate into AM building components. And to verify suitable AM processes, geometries, functional scenarios, and their optimization potentials.

Expected outcomes:

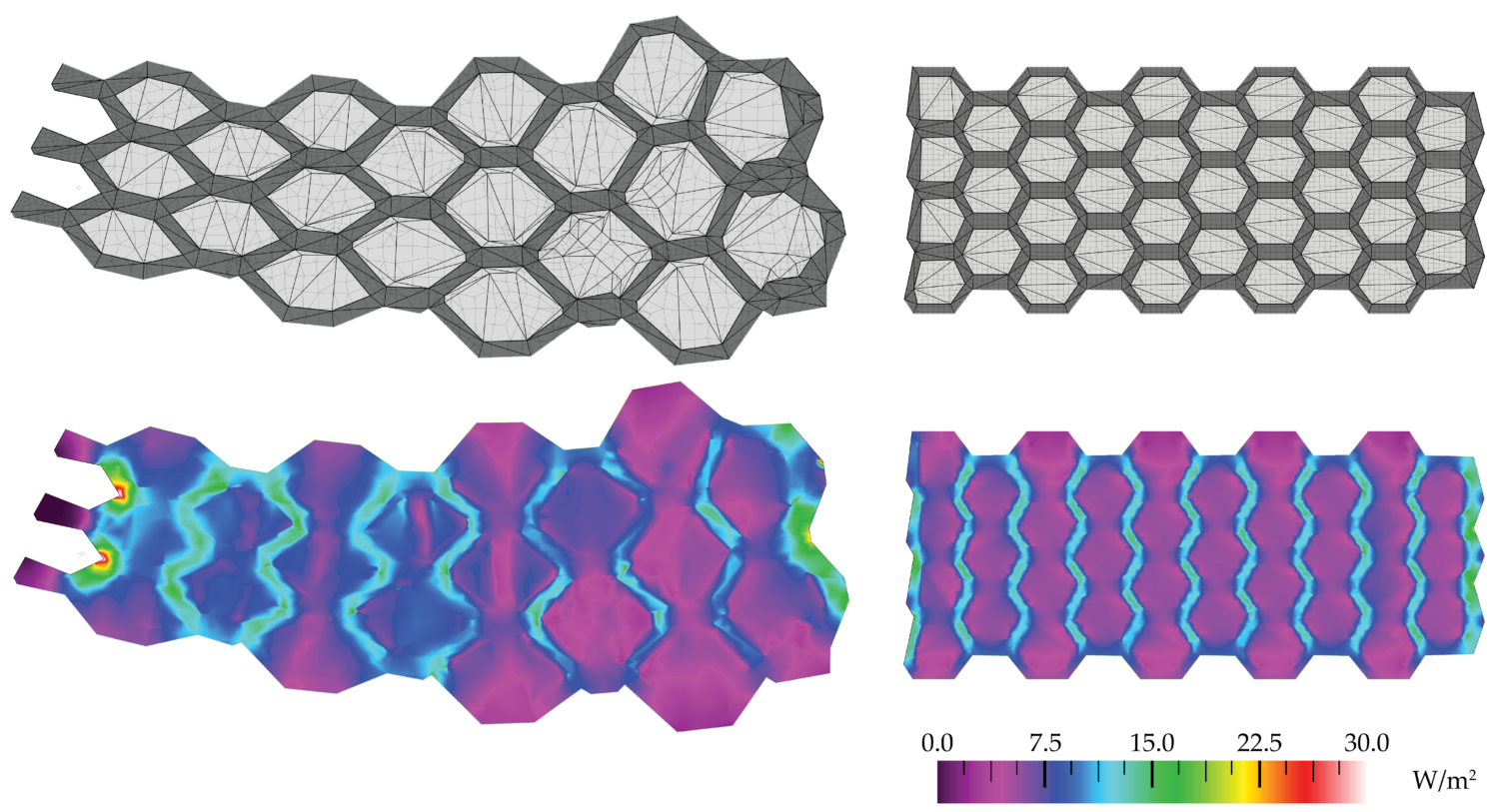

- An analytic process to explore how complex AM component geometries can achieve minimum material usage and performance optimized intrinsic characteristics.

- Methods to incorporate optimized functionalities into AM building components through a simulation-based process.

- AM building components with multiple integrated passive and active functions.

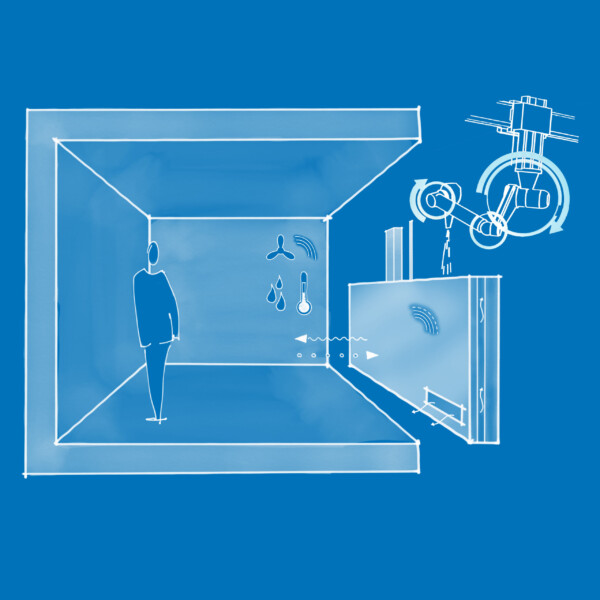

- An intelligent management system for enhanced energy performance and better thermal and visual comfort in built environments.

Approach

- The methodology is based on simulations that predict specific indoor comfort metrics considering location, function, and climatic conditions under the components’ material properties.

- Assessment of multiple prerequisites for passive and active building component functions.

- A simulation-based parametric design process to explore, forecast, and quantify the benefits of multiple functionalities through energy efficiency and comfort-conscience stance.

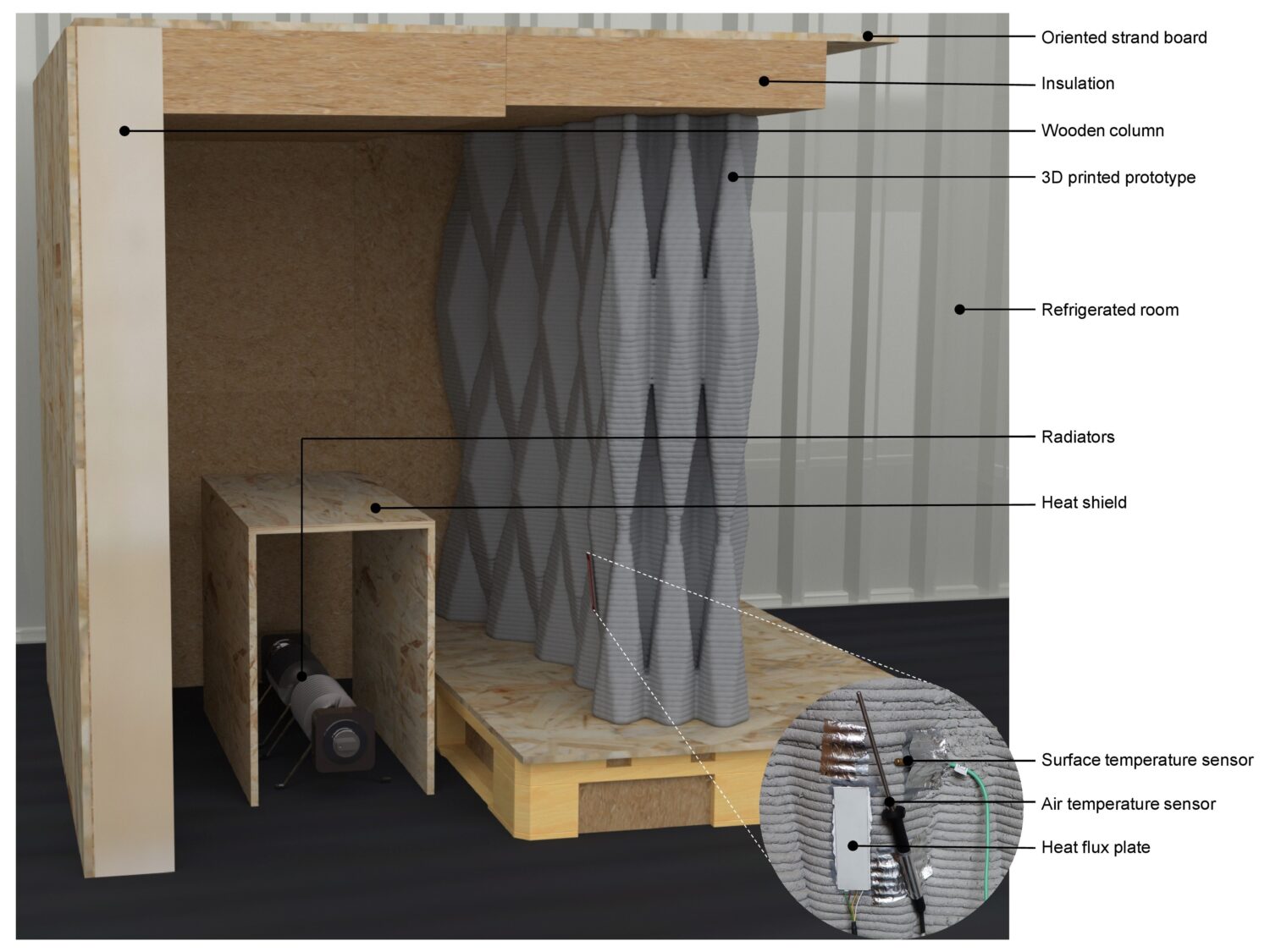

- Established upon performance and potential analysis, variants are turned into physical mock-ups.

- Selection of prototypes, including their functional integrated building components, for testing in the research laboratory.

- Testing manufactured prototypes, using testing protocols to verify and validate the various simulation models.

Networking with other projects

C03 provides performance-based information for the connected projects in research area A. On the other hand, the simulation results will guide practicable design criteria required to fabricate demonstrator objects together with A- and B-projects. Furthermore, the evaluation and test results of C03 for building components with their integrated functions will be exchanged within the area C and provided to the A-projects.