Project C 05

Networking with other projects

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Subproject C05 discusses the potentials and challenges of robotic manufacturing techniques for proposing and evaluating the connections utilized for precast printed concrete elements regarding structural criteria.

Considering the properties of various concrete Additively Manufacturing techniques (particle-bed, extrusion, shotcrete), the features of different Subtractive Manufacturing techniques (milling, sawing) along with the diverse capabilities that are expected from connections (regarding their type of structural usages), can illustrate the range of parameters and variables regarded in this subproject.

Hence, based on the AM processes, this project discussed multi issues, including – proposing and assessing different types of dry concrete joints, – tangential behaviours of the milled and/or printed specimens (e.g. effects of smoothness) and – comparing the performances of subtractive and additive manufacturing methods (e.g. direct printed, milled joints).

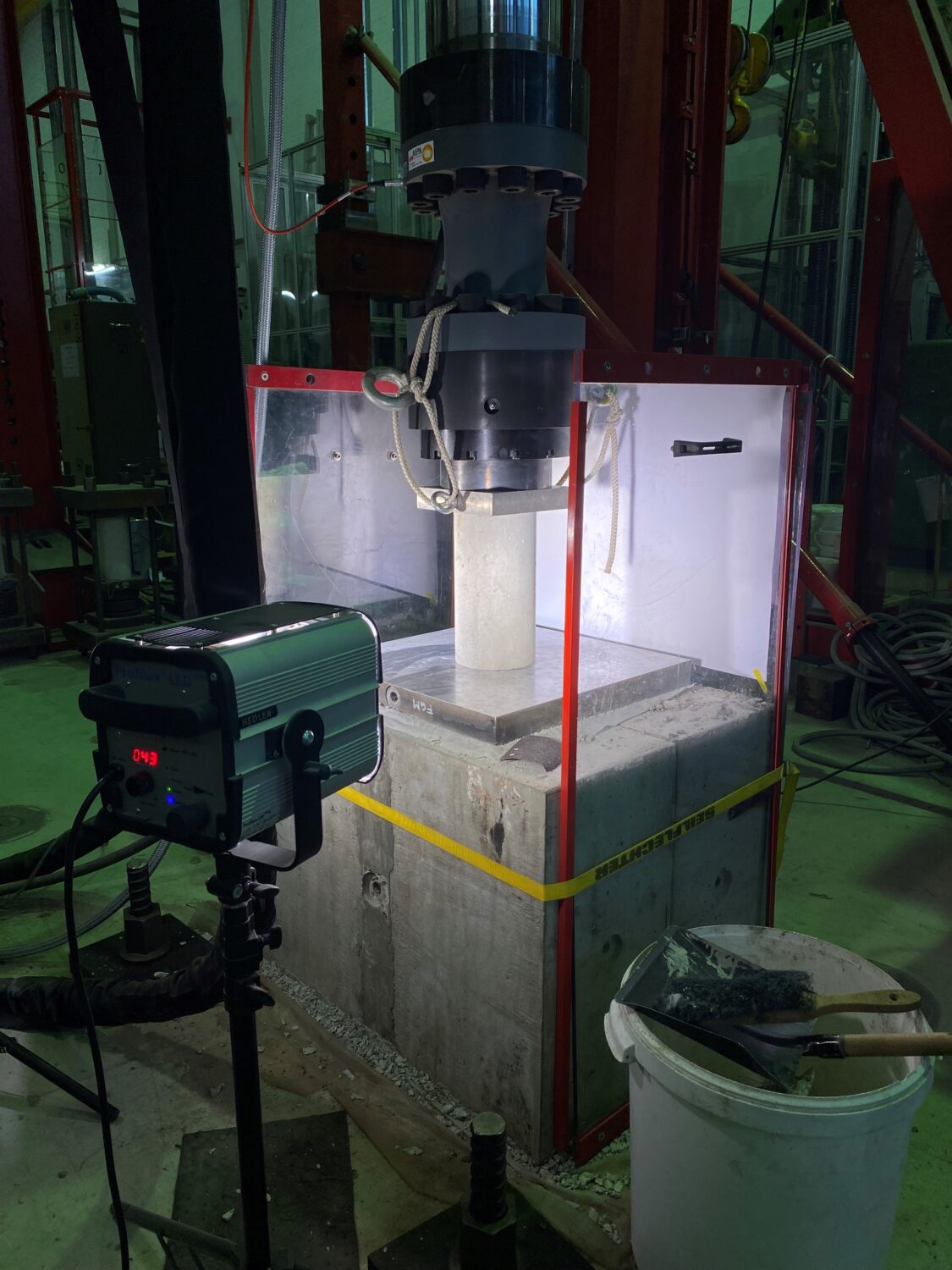

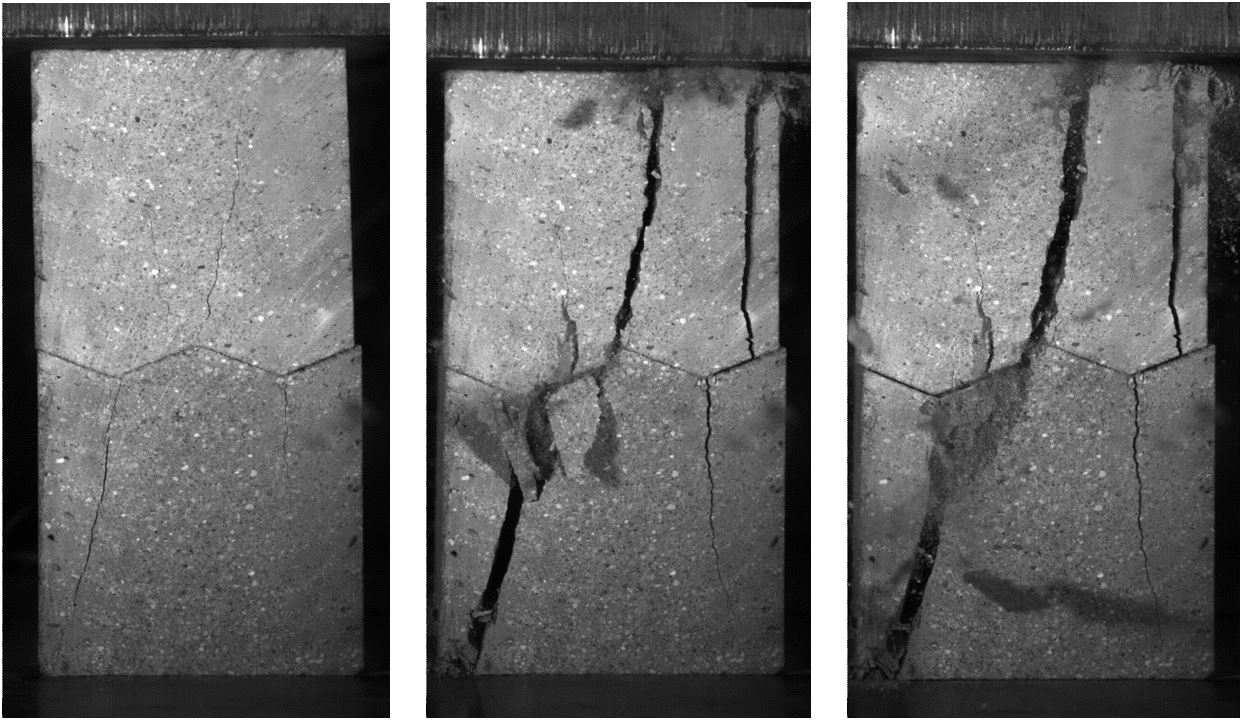

The investigation strategy comprises experimental, numerical and theoretical methods and is consecutive in scale (micro, meso) as well as loading type (compression, shear). Regarding the influences of all mentioned parameters on the performance of each dry milled joint, the results will provide fundamental insight into the load-bearing behaviour of AM dry joints.

Objectives

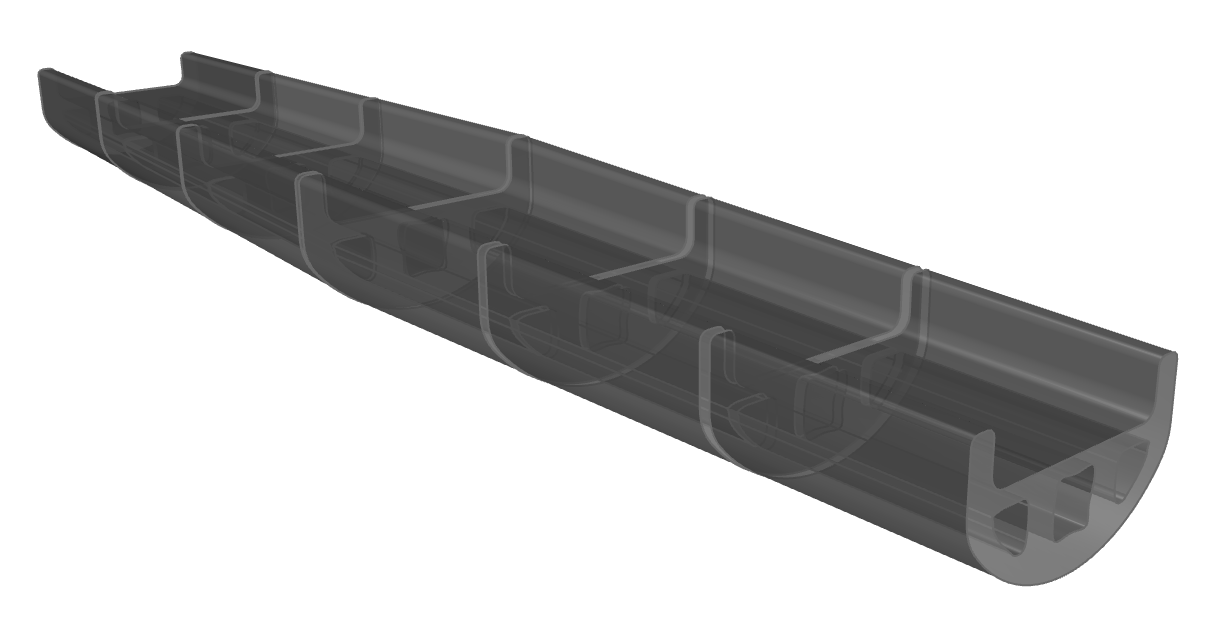

Subproject C05 investigates the execution, production process and load-bearing capacity of dry joints in AM concrete segments. Therefore, it contains four consecutively structured working packages, WP1-WP4 (Figure). WP1 aims to design and select joints’ profiles for 3D-printed elements. A set-up database (joint catalogue) is used, containing the main imaginable joint profile types and geometries taken from timber, steel and bionic connections. Evaluation criteria, weighting factors and an algorithm evaluate the gathered joint profiles regarding the applicability for 3D-printed concrete elements. The algorithm then selects four joint profiles to be further analyzed by packages WP2, WP3 and WP4. In WP2 and WP3, the goals are to understand the load-bearing behaviour under compression and shear by numerical simulation and experimental testing, while in WP4, the results of the previous packages are used to design, simulate and test a 3D-printed and via dry joints connected component.

Methods and Approach

- Joint Selection

The selection of joints is based on a joint catalogue, i.e. database that contains an enormous variety of joint configurations. The ideas of the joint profiles come from segmental concrete constructions, which can be adapted from timber, steel or bionic structures. Regarding the impossibility of investigating all joint profiles numerically and experimentally, along with the disability of the standard analysis in considering different aspects of the dry joints, a preselection based on the engineering judgment is necessary. In principle, various criteria are used to evaluate each joint profile, and then, subsequently, the joint profile with the best evaluation is selected for further investigation. The evaluation is based on a scoring system and weighting factors for each criterion considering the main goals of subproject C05.

- Joint Investigation

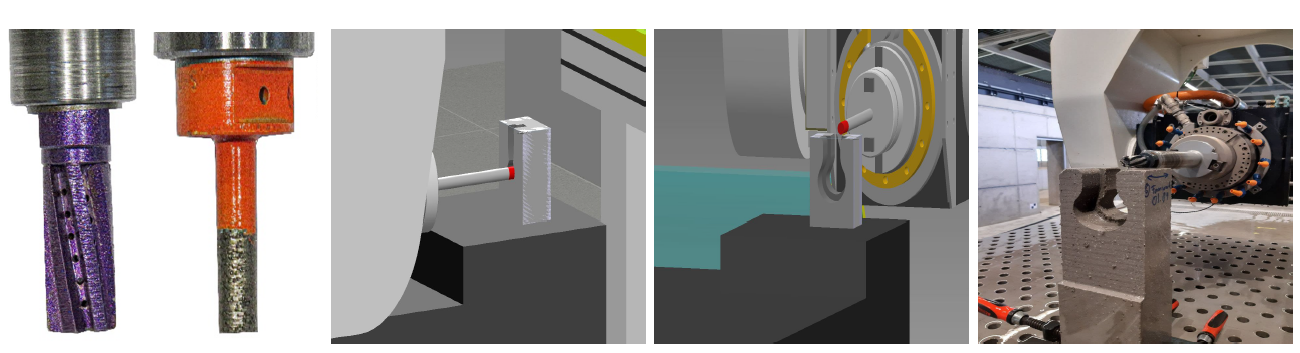

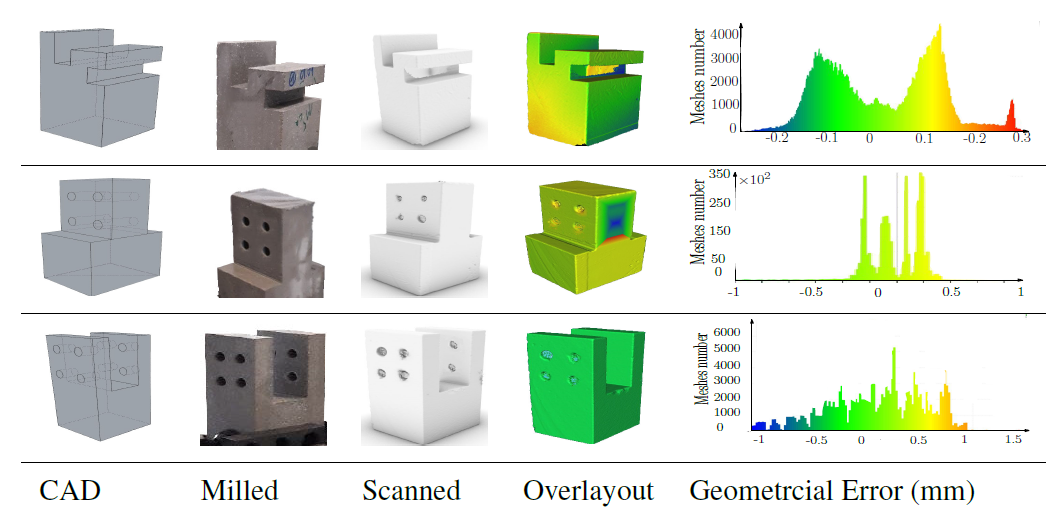

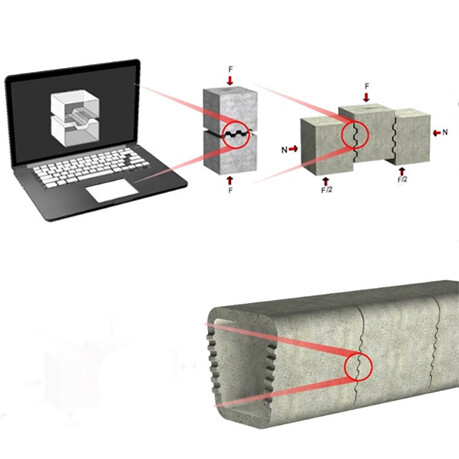

The selected joint profiles are investigated numerically and experimentally to understand the load-bearing behaviour. The blank specimens for the selected joint profiles are produced by every AM process (shotcrete, extrusion and particle-bed). The joint profile geometry is manufactured by subtractive post-processing, i.e. CNC-milling and CNC-sawing. Laser scans evaluate the accuracy of the CNC tools before optimizing the manufacturing process, e.g. which tools suits best for which joint profile. The numerical investigation serves at first as a preliminary test of the experimental investigations. Later, the gained information of the experiments is implemented into the numerical models to simulate the tests with even higher accuracy.

- Calculation approach for dry joints

Every numerical and experimental investigation result, along with the subtractive post-processing outcomes, are collected to set up a calculation approach for dry joints in AMC. The calculation approach is calibrated by a large scale demonstrator test with pre-stressed joints between AMC segments.

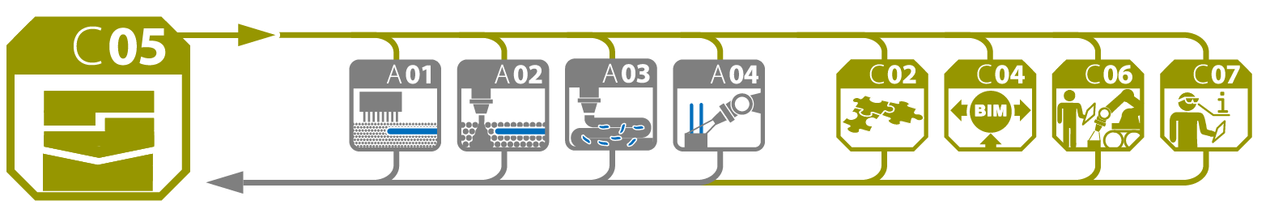

Networking with other projects

Subproject C05 investigates the load-bearing behaviour of dry joints in AMC. The blank specimens for the experimental investigations are manufactured by every AM process (shotcrete, extrusion and particle-bed). Furthermore, the mechanical material behaviour is required to understand the load-bearing behaviour of dry joints and for setting up a calculation approach. Therefore, C05 is closely networked with the A-subprojects, especially A01 to A04 providing the specimens and mechanical behaviour of the material.

B04: Subproject connects, providing C05 with laser scans and evaluation codes to determine the joint profile accuracy. Their contribution in live scans of the printing concrete in C05’s subsequent steps (e.g. subtracting the reinforced joints) is a valuable support.

C02: This contribution is substantial to us regarding their developing technique for 1- optimizing the new types of connections and 2- their technical efforts for assigning the optimum places to the connections. Selecting the places of the connections in the structures is the primary key to designing and assessing desirable connections.

C04: Generation of the Building Information Models can cooperate closely with C05, while the structural performance of the building (all analyzing data) directly relates to their joint performances. Likewise, exchanging the varieties of digital data collected by sensors, scanners elements’ geometries can in a desirable subtractive manufacturing process and assembling the elements be frequently by C05 utilized.

C06: This networking regarding two main technical supports are essential: first to evaluate the geometrical accuracy of C05’s connections through a comparison to the initial CAD files (e.g. as live scan), then their scanned models of A04’s manufactured elements, as the C05’s final large scale demonstrator to be used as our initial models for developing the CNC codes.

C07: This networking, which can be further developed through information exchange, enables the C05’s to ensure accordance with proper construction product regulations and other TRR subprojects.