Project C 09

Environmental Life Cycle Assessment – Determination of Ecological Sustainability Potentials by AMC

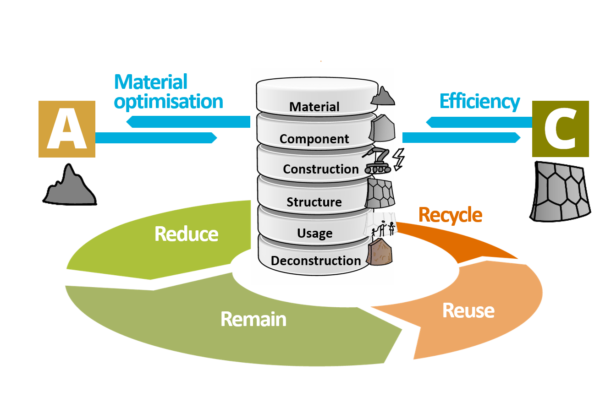

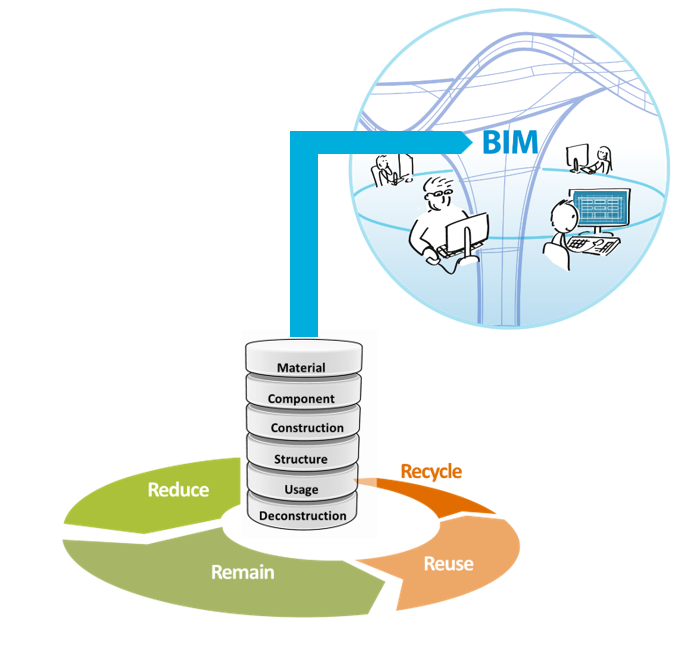

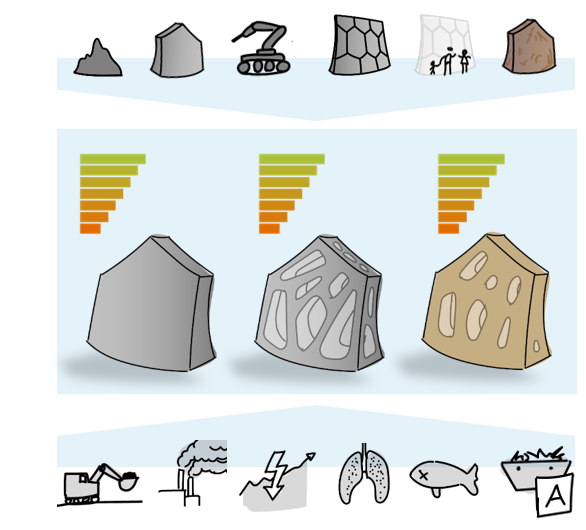

Additive manufacturing in construction (AMC) is a viable option for use in tomorrow’s construction industry due to a diverse set of advantages, e. g. reduced costs, saved time, reduction of waste and a highly increased design flexibility compared to conventional construction. Complex, customised, structural optimised and/or multifunctional components can be designed and may contribute to a material-reduced, durable, and circular way of building. Precisely these potentials will be quantified and optimised in C09 by means of environmental Life Cycle Assessments (E-LCA) from cradle to cradle (from raw material excavation, manufacturing, use, end of life as well as the reintroduction into a technical cycle). Based on global sensitivity analysis, product environmental footprint category rules (PEFCR) are developed to guarantee high quality and transparency of future E-LCAs for AMC. Dominance analyses are used to identify significant environmental impacts.

Aim

This project develops a holistic methodology based on in-depth E-LCA specially tailored to the challenges of AMC to fairly assess and reduce the environmental impacts of the construction sector. Further project aims are the implementation of a modified circularity indicator in environmental sustainability assessment and the creation of an ecological best practice catalogue based on case studies. Uncertainty analysis will be tailored to environmental sustainability assessment of AMC.

Methods

C09 answers the following questions:

- How large is the environmental footprint of additive manufacturing techniques applied in the A-projects and what are the most efficient measures to reduce the footprint?

- How does the implementation of circular design strategies of AMC affect the environmental impact and how can circularity be reliable assessed for AMC?

- Which manufacturing process is best suited for a specific application in terms of general performance (strength, durability, and functionality), and environmental sustainability?

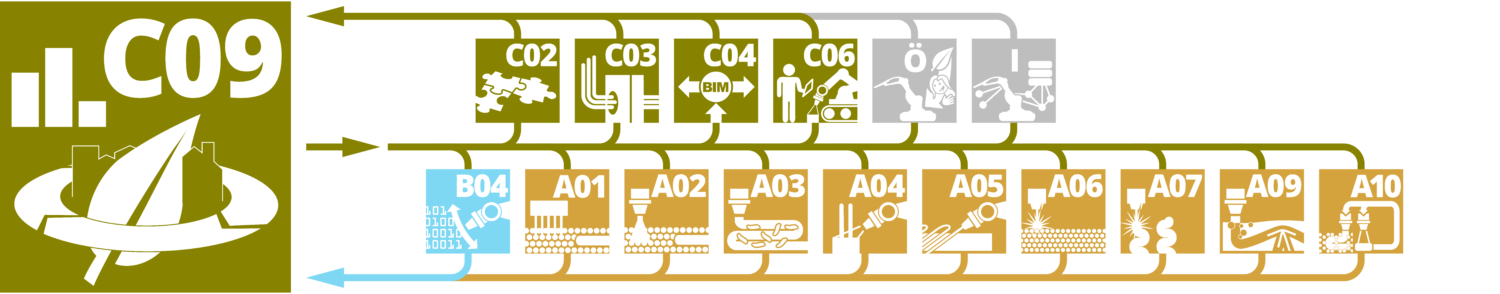

Networking with other projects

C09 provides comprehensive support to assess and reduce environmental impact for all A-projects and collects data on processes and materials of the A-projects and B04 from the beginning. C09 profits from information on technological feasibility in terms of manufacturing complex (all A-projects), material-efficient (C02), deconstructable (all A-projects) and multifunctional (C03) components and structures. Together with the A-projects, design strategies like design for durability (A01, A02, A03, A04, A06, A07, A09), design by availability (A09, A10) and design to reuse (all A-projects) will be assessed in terms of environmental impacts and compared to conventional construction. By working closely with the projects mentioned above, a targeted, holistic and quantitative assessment of the ecological dimension of sustainability can be made, which is completed by considering buildability in collaboration with C06. C04 already has experience in the integration of sustainability aspects and supports C09 in implementing the developed Best Practice catalogue and the developed LCA methodology in FIM. Finally, close cooperation with the Ö-project is anticipated to communicate environmental sustainability of AMC to future decision-makers.