Education

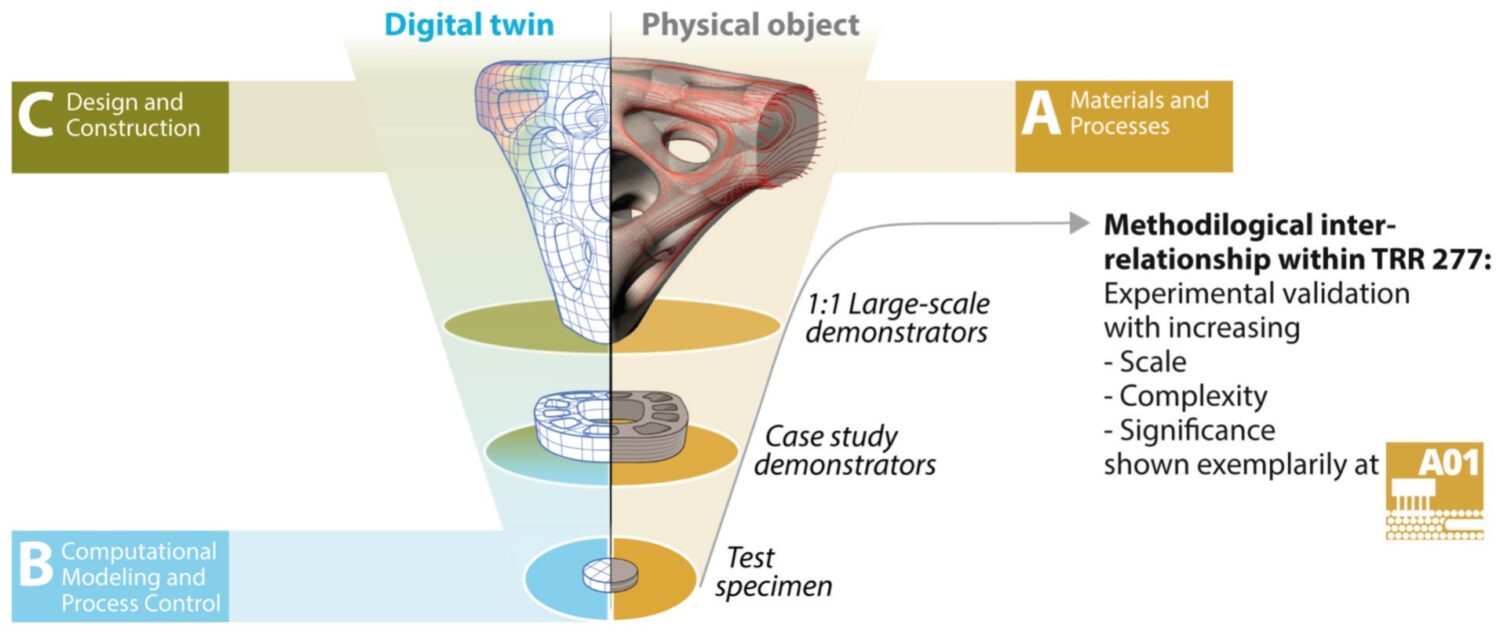

Figure 1 The methodological connection between the three focus areas A, B, and C, within the TRR 277 AMC is being investigated through the validation of their interaction via test specimen, prototypes, and large-scale demonstrators.

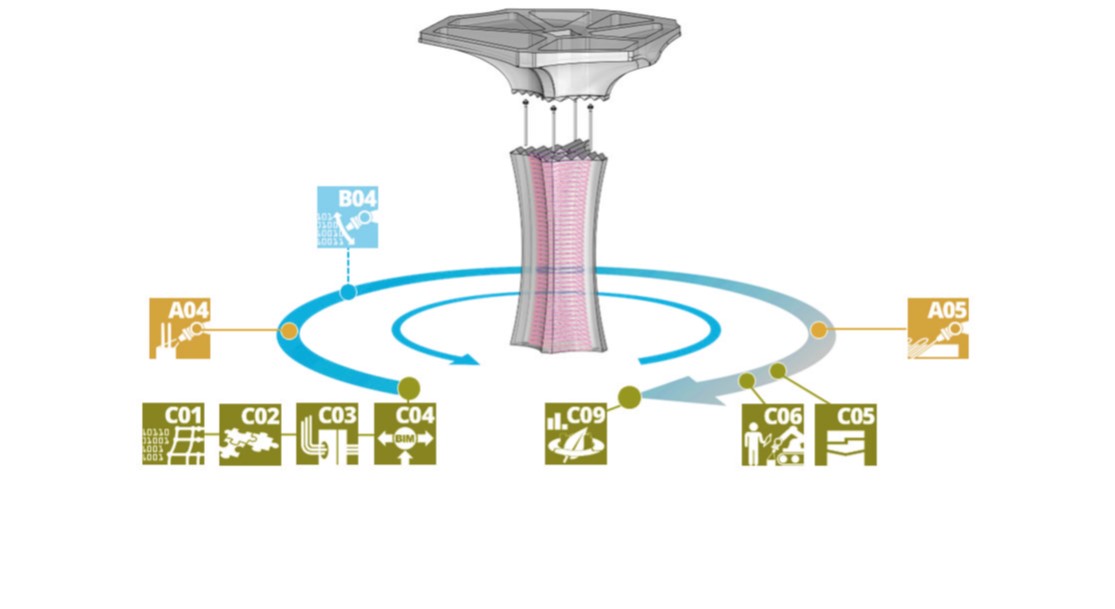

Figure 2 Exemplary networking scheme within the three focus areas A, B and C on behalf of the Shelltonics Collaborative Demonstrator.

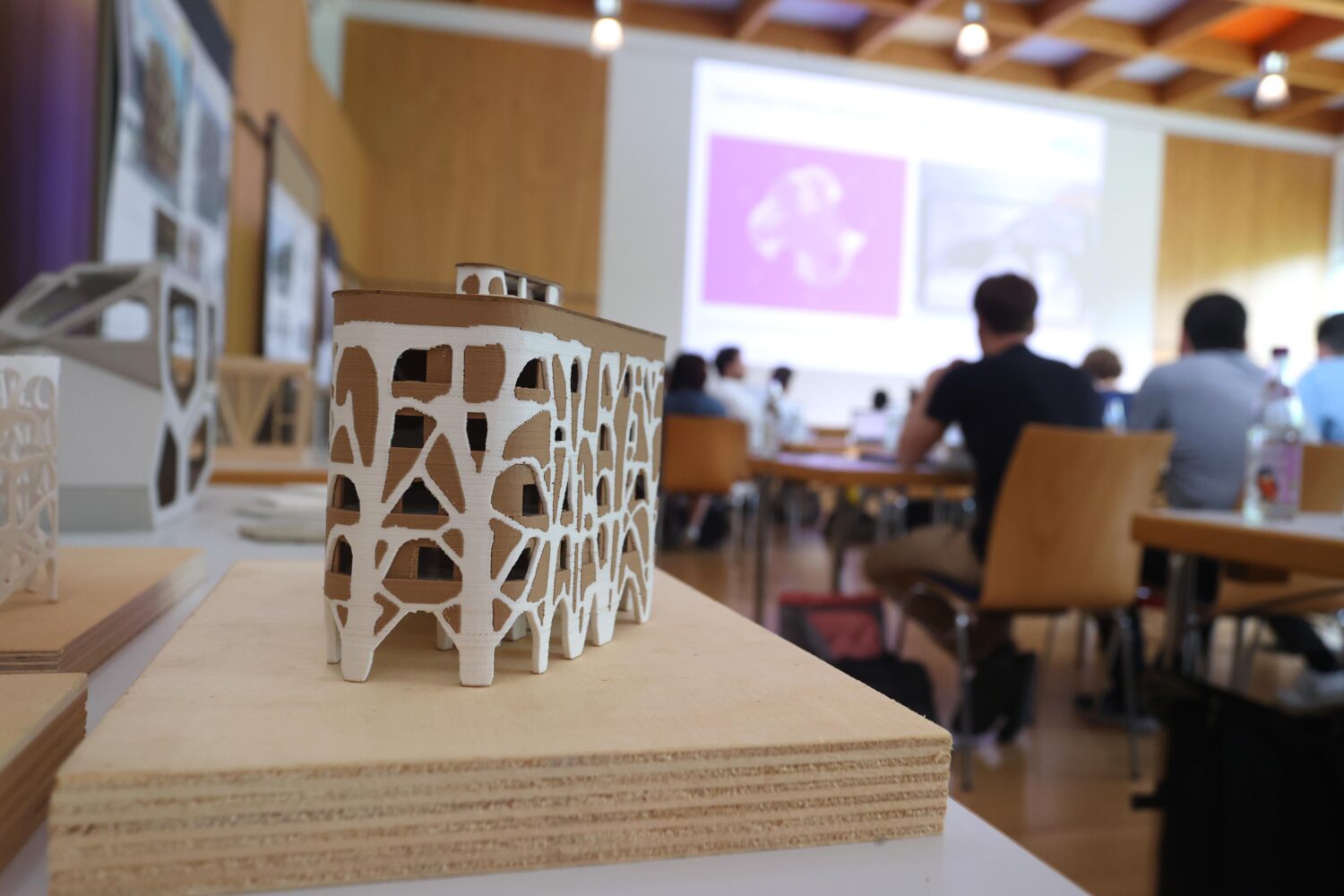

Explorative Teaching – from AM to Arch, Credit: Karl Joseph Hildenbrand / TUM

Explorative Teaching – from AM to Arch, Credit: Karl Joseph Hildenbrand / TUM

Final presentation; Explorative Teaching – from AM to Arch, Credit: Karl Joseph Hildenbrand / TUM

LabDay, Jan´23 source: Dieter Beckert

Flyer Workshop PDF-Format

AMC-Workshop „revAMp“ at the AdvanceAEC autmn school 2022

Collaborative Demonstrator

download here the AMC Collaborative Demonstrator Booklet

The „AMC Collaborative Demonstrators“ . large-scale additively manufactured sections of building and infrastructure designs at 1:1 scale – serve the purpose of investigating and experimentally

validating the methodological connection and interaction between the three main focus areas A (Materials and Processes), B (Computer-aided Modelling and Process Control), and C (Design and Construction) within the Collaborative Research Centre TRR 277 Additive Manufacturing in Construction (AMC).

The AMC was established by the Technische Universität Braunschweig and the Technical University of Munich in 2020, investigating large-scale Additive Manufacturing (AM) as a new key technology for tomorrow‘s construction. The research is based on the hypothesis that AMC can combine the advantages of artisanal construction and craft, namely individualised and non-standardised manufacturing, with the advantages of industrial mass production, namely precision and cost-efficiency. With the concept of mass customisation, new degrees of freedom in design and higher material efficiency in construction can be achieved, mainly because material can be applied only where it is structurally and functionally needed. Within the scope of the AMC, a wide range of mineral-based materials, mineral composites, metals, earth-based materials, fibre-reinforced polymers, and wood are being explored for various additive manufacturing processes. What unifies this diversity of materials methodologically is a profound focus on material-process interaction. In the integrated approach to digitally supported construction, the material and the manufacturing process are consciously considered as a cohesive entity, deeply interrelated and complementary to each other.

Furthermore, the research conducted by the AMC is essentially interdisciplinary and goes beyond purely technological investigations. It not only examines material-process interactions but also encompasses simulation and modelling, structural design, and the integration of additive manufacturing in the wider construction ecosystem. The methodological interconnection of the three main focus areas A, B, and C, is based on experimental validation through the production of test specimens, demonstrators of case studies, and large-scale demonstrators. This approach is used for the validation of projectspecific research questions. (Figure 1).

Additionally, the design and fabrication of large-scale Collaborative Demonstrators serve as a platform for interdisciplinary teams of AMC researchers across the fields of civil engineering, architecture, materials science, and mechanical engineering to experimentally test and validate the integration of materials and processes (focus area A), computer-aided modelling and process control (focus area B), and design and construction (focus area C) featuring sections of building and infrastructure designs at 1:1 scale (Figure 2).

The goal is to test, compare, and evaluate the typical characteristics of individual AMC processes, such as resolution and granularity, mechanical properties, and load-bearing capacity, building physics usability, geometric freedoms, etc., in various building and infrastructure applications. Contrary to focusing on a single process, new AMC technologies are examined and explored in terms of their broad applicability and potential in sustainability, productivity, and resource efficiency. As such, the Collaborative Demonstrators aim to transfer research results into technically mature applications outside market mechanisms. In summary, this approach aims not only to make the research findings of the AMC tangible through potential applications of AMC technologies in the construction sector but also to provide conceptual perspectives and drive and motivate future AMC research.

AMC COLLABORATIVE DEMONSTRATORS

Validation of Integrated Research Methodologies through Collaborative AMC Prototyping

In association with Additive Manufacturing in Construction AMC TRR 277

Publishers: Dörfler K., Hack N., Henke K., Kloft H.,

Published at: Technische Universität Braunschweig

Place of Publication: Braunschweig

Managing Editor: Janna Vollrath

Associate Editors: Moritz Scheible, Julia Fleckenstein, Anne Niemann

Layout: Janna Vollrath, Lea Löwe, Moritz Scheible

Typeface: Dinamo, ABC Favorit

Printing and Binding: Offsetdruckerei Karl Grammlich GmbH

ISBN: 978-3-910750-05-0

DOI: 10.24355/dbbs.084-202310041154-0

© 2023 Technische Universität Braunschweig

All rights reserved

No parts of this book may be used or reproduced in any manner without the written permission of the publisher

Explorative Teaching – From Additive Manufacturing to Architecture

Download here the AMtoARC publication as preprint (HighResolution 70MB)

Download here the AMtoARC publication as preprint (LowResolution 32MB)

Explorative teaching breaks with common and standardized design teaching methods. It is the quest for a new symbiosis of ecological materials and digital fabrication. How we design (space and design) and what we design with (materials, processes and simulation techniques) are two inseparable aspects of our future activities as architects and engineers. Substantial sustainability only emerges when all these aspects are combined into a complex whole. The obvious danger of “technification”, as unfolding at the latest with Material Cultures (see Material Cultures: Material Reform, Building for a Post-Carbon Future), versus the potential to combine ecological materials with the benefits of robotics, needs to be explored by experienced architects in research-based teaching. While the first generations of digital developments focused on the challenge of advanced geometry, the urgency of how we treat nature differently is now the driving force. Without innovation in building design, we will not be able to create the buildings of the future. This is where teaching and research must realign to play a leading role in recalibrating the design process.

Explorative design thereby promotes the interaction of technology and design and transfers individual inventions into a coherent overall construct. The holistic questions that come to light in the course of an architectural conception change the perspective within the research work. In turn, scientific findings offer designers a broad spectrum of new procedures and techniques that result in a sustainable architecture within the planetary boundaries.

Explorative teaching was investigated within the project “From Additive Manufacturing To Architecture” in the summer semester of 2022. In a cooperation between TU Braunschweig and TU Munich so-called “A-Projects” from the collaborative research center AMC TRR 277 were examined. This lead to the development of constructive structures in digital fabrication. In a second step, concepts for buildings were drawn up from the structural solutions, giving the constructive idea an aesthetic and architectural form. Finally, these student designs were technically refined and manufactured as collaborative demonstrators on a scale of 1:1. Innovative research approaches were integrated into the design and construction planning process of master student projects from the very beginning. The resulting architectural and technical findings were subsequently critically reflected upon within the scientific spectrum of the AMC TRR 277.

Plenty of inspirations emerged from the collaboration and interaction between teaching and science. Profound questions within the design process opened up various new perspectives on the current research approaches. The format of an interdisciplinary and explorative master project accompanying the science process will therefore be established in a regular manner for the next semesters. In a fruitful exchange between students and researchers Additive Manufacturing can be brought to the scale of Architecture.

Authors: Helga Blocksdorf/Moritz Scheible

From Additive Manufacturing to Architecture Teaching collaboration

Technische Universität Braunschweig:

ITE Professorship for Digital Fabrication

Prof. Dr. sc. ETH Norman Hack; M.sc. Philipp Rennen

www.tu-braunschweig.de/ite/

IKON Institute for Construction

Prof. Helga Blocksdorf; Dipl. Ing. Moritz Scheible

www.ikon-institute.com

Technische Universität München:

TT Professorship Digital Fabrication

Prof. Dr. sc. ETH Kathrin Dörfler; Dipl. Ing. Julia Fleckenstein

https://www.arc.ed.tum.de/df/professorship/

Chair for Design and Construction

Prof. Florian Nagler; Dipl. Ing. Anne Nieman

https://www.arc.ed.tum.de/lek/aktuelles

From Additive Manufacturing to Architecture – Information

AMC LABDay

The basic idea is to introduce students to the possibilities of 3D printing for architecture and for the entire building industry. For this purpose, a workshop is initiated that gives students a concrete understanding of the digital fabrication process from design to production. Using clay as an example, the students can directly participate in creative design, augmented reality, software and robotic 3D printing production. The special feature of the workshop is that the students themselves directly design an object digitally and this object is then printed by a robot.

Result

an understanding of the processes of digital building – from creative design to 3D-printed building – and their own designed object. The new 3D technologies are massively changing the construction industry and opening up interesting new job profiles.

Aim

To get students excited about the new technologies of 3D printing and to see themselves in the field of additive manufacturing. Increase the number of female students in STEM courses such as civil engineering, mechanical engineering and architecture.

Target group

High school students/Upper School (from grade 11)

“revAMp”

As part of the AdvanceAEC network, TRR 277 has organised lectures within the AdvanceAEC network and doctoral researchers gave a well-regarded workshop at the AdvanceAEC Autumn School 2022.

The Autmn School is aimed at early career researchers, e.g. master students, PhD students and postdocs from the partner institutions of the network.

The full-day workshop “revAMp – Additive Manufacturing in Construction: In situ Retrofitting Using AM with Mobile Robots” was going to experimentally explore whether the deployment of mobile robots on building sites could be utilized for retrofitting, customized renovation, or repair by applying in situ extrusion 3D printing technology.