Project B 06

Material Modelling and Simulation of Deposition AM Processes on the Part Scale

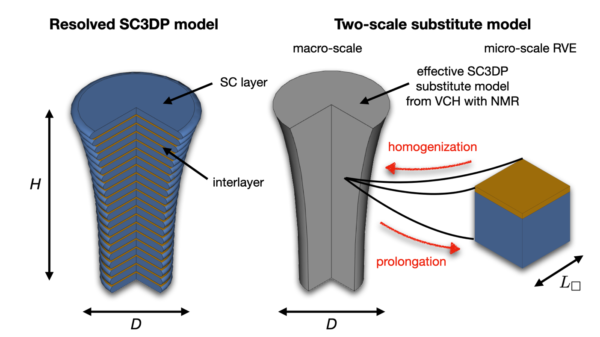

This project aims at providing a modelling and simulation approach across the scales starting from consistent material models for bulk deposited AM concrete and its interlayers towards a reduced substitute model for fast simulations of complex geometries on the part-scale. More explicitly, the goal is to describe the material properties of AM parts during the printing process, whereby the material modelling of a layer sets in directly after the deposition of the fresh concrete. Without loss of generality, shotcrete (SC3DP, shotcrete 3D printing) is considered as a prototype material throughout this project in the 2nd funding period.

Methods

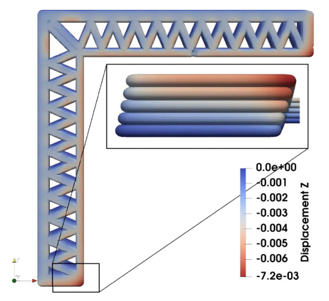

To achieve these objectives, the project combines visco-plastic material modelling of fresh bulk SC3DP as well as its interlayers. A novel experimental setup will be developed in close collaboration with project A04 within the 2nd funding period. The resulting material model together with geometry information is processed via Variationally consistent Computational Homogenisation with Numerical Model Reduction. This allows to reduce the complexity of the problem and to derive a unified visco-plastic surrogate model that comprises both bulk and interface properties as well as their evolution over time. Finally, the properties of SC3DP can be simulated for complex geometries on the part-scale in an inexpensive fashion by means of the Finite Cell Method. Furthermore, the effective material model on the part-scale will be integrated into the surrogate modelling approach developed in project B04.

Networking with other projects

This project sets out to provide a scientifically sound and accurate material formulation for the novel process of SC3DP as investigated in project A04. It combines this material formulation with the geometric flexibility of the Finite Cell Method to be able to deliver a highly accurate predictive tool for deformations and failure during the manufacturing process. Such highly accurate models, however, may by construction not be fast or deliver an online monitoring per se. Yet, other B projects such as B04 will either directly use the material description or derive even simpler, faster coarse grain computations for a quick assessment of stability on the basis of the fundamental research results in B06. Moreover, the methodology and framework developed in this project are constructed to be as general as possible. They are, therefore, to be adapted to other kinds of deposition processes. In addition to providing such fundamental analysis, we investigate the incorporation and applicability of fabrication information models as generated by C04 for production processes and will profit from the process monitoring planned in C06.