Project A 09

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

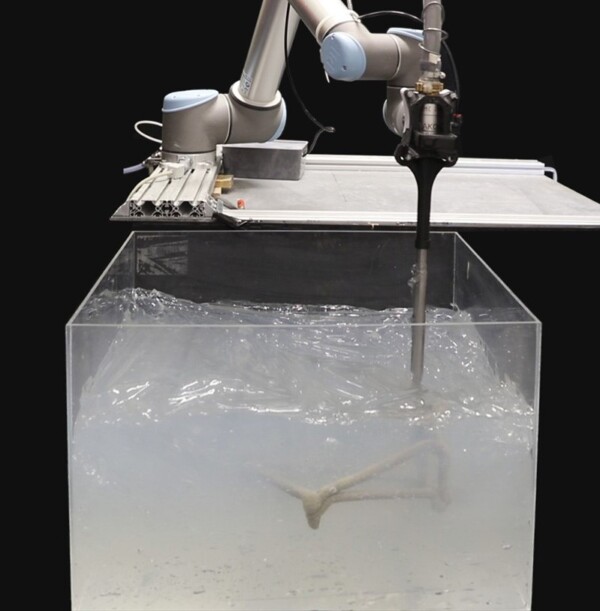

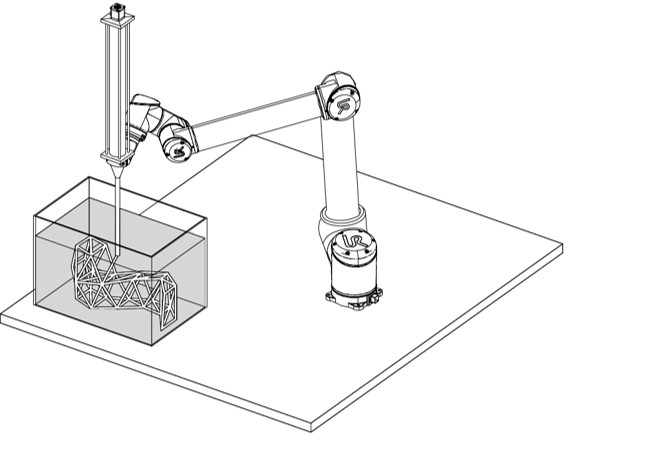

Injection 3D Concrete Printing (I3DCP) is a new additive manufacturing process that was developed independently of the AMC in 2018 by researchers at Technische Universität Braunschweig and in variants by others, e.g. I3DCP will hence join the TRR 277 as a new project. The basic principle of I3DCP is that a fluid of material A is robotically injected into another fluid of another material B. The role of material B is to support material A such that material A maintains a stable position. In general, I3DCP can be categorized into three sub-categories:

(a) Concrete in Suspension (CiS): injection of concrete into a non-hardening carrier liquid;

(b) Suspension in Concrete (SiC): injection of a non-hardening suspension into a concrete; and

(c) Concrete in Concrete (CiC): the injection of a concrete into another concrete with different properties.

Aim

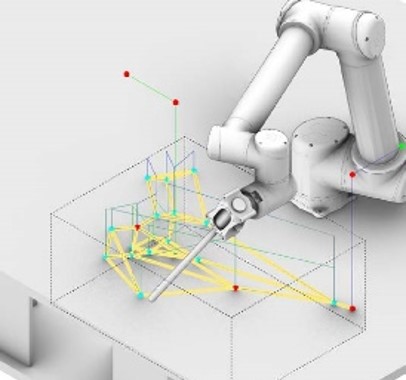

The research project aims to fundamentally understand the two I3DCP techniques CiS and CiC with regard to the underlying material and process interaction as well as its process applications and control. Therefore, the following topics need to be investigated in thorough depth in order to enable a robust and controlled process: (i) rheology and interaction of the two materials, (ii) path-planning algorithm and structural design with graphic statics, (iii) reinforcement integration, and (iv) failure mechanisms and predicting print stability.

Networking with other projects

The project A09 is in direct collaboration with projects from the TRR 277 in order to improve the basic understanding of the principle of I3DCP and enhance the process. Therefore, in the planning phase of physical specimen and demonstrators, a collaboration with C02 (finding design and shape) and B04 (3D path planning) is planned. For the production of specimens, data will be provided to B03 who will focus in modelling the process details such as multi-strand-crossing. For data acquisition after production a collaboration with C06 is envisaged and the obtained data will be also provided to C01 in order to enable an as-is-simulation. Overarching is a collaboration with C09, who will investigate sustainability aspects of the process and will give advice in order to improve the process in this regard. All collaborations are described in detail in the corresponding work packages. In addition to the collaboration with other projects, there are also two associated researchers who have been significantly involved in the research to date, and whose input is also beneficial for further research. On the material side, this is Dirk Lowke, and with regard for structural engineering, Harald Kloft.