Project A 08 (completed)

Structural Timber by Individual Layer Fabrication (ILF)

In project A08 a novel fabrication process named ‘individual layer fabrication (ILF)’ is being investigated, which allows the use of wood in the additive manufacturing of structural elements. In this process the parts are built up by laminating successive layers of individually contoured panels that are additively manufactured by selective binding of wood particles. As each layer is fabricated separately, mechanical pressure can be applied in the production of these bespoke wood composite panels, leading to a significant reduction of binder content and an increase of mechanical strength.

Objective

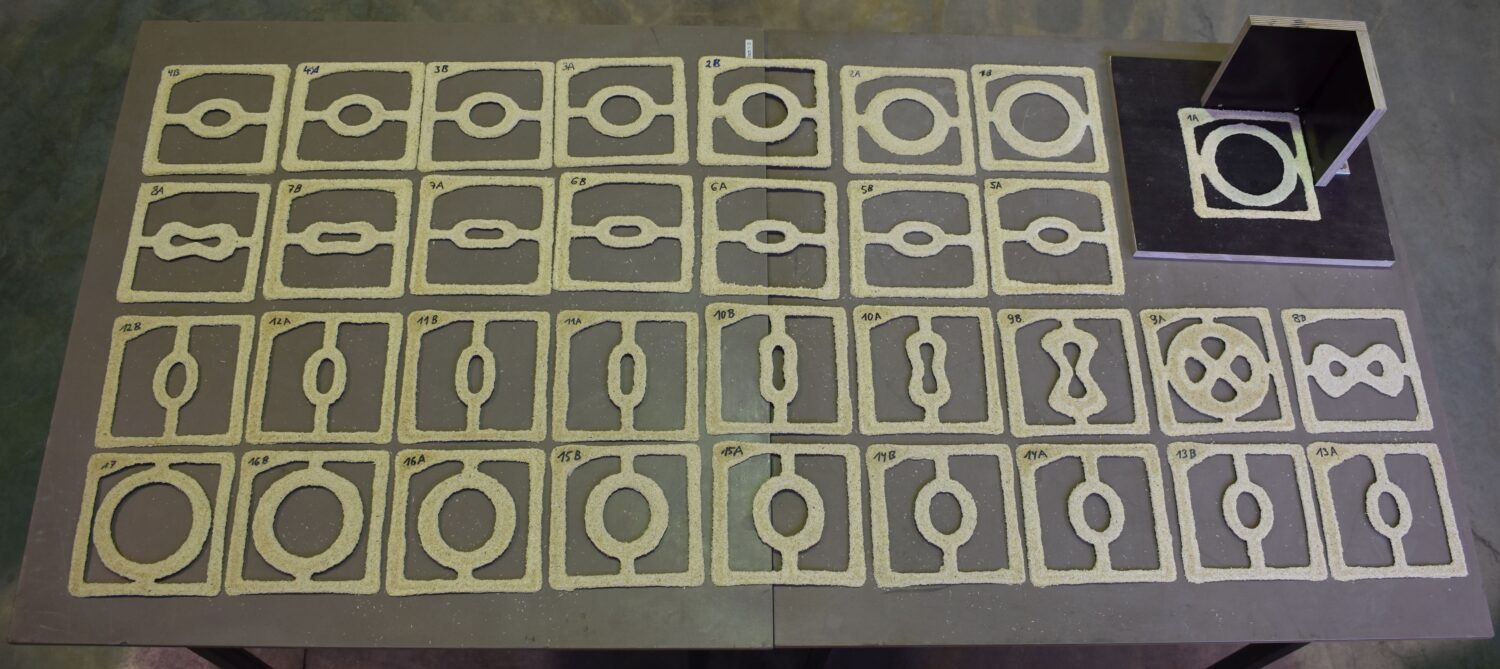

The renewable resource wood is becoming increasingly popular as feedstock material for additive manufacturing. Reasons for this can be environmental aspects, cost reduction or the enhancement of material properties. The aim of project A08 is to facilitate additive manufacturing of wood composite parts that are, in terms of scale and material properties, suitable for an application in construction.

Approach

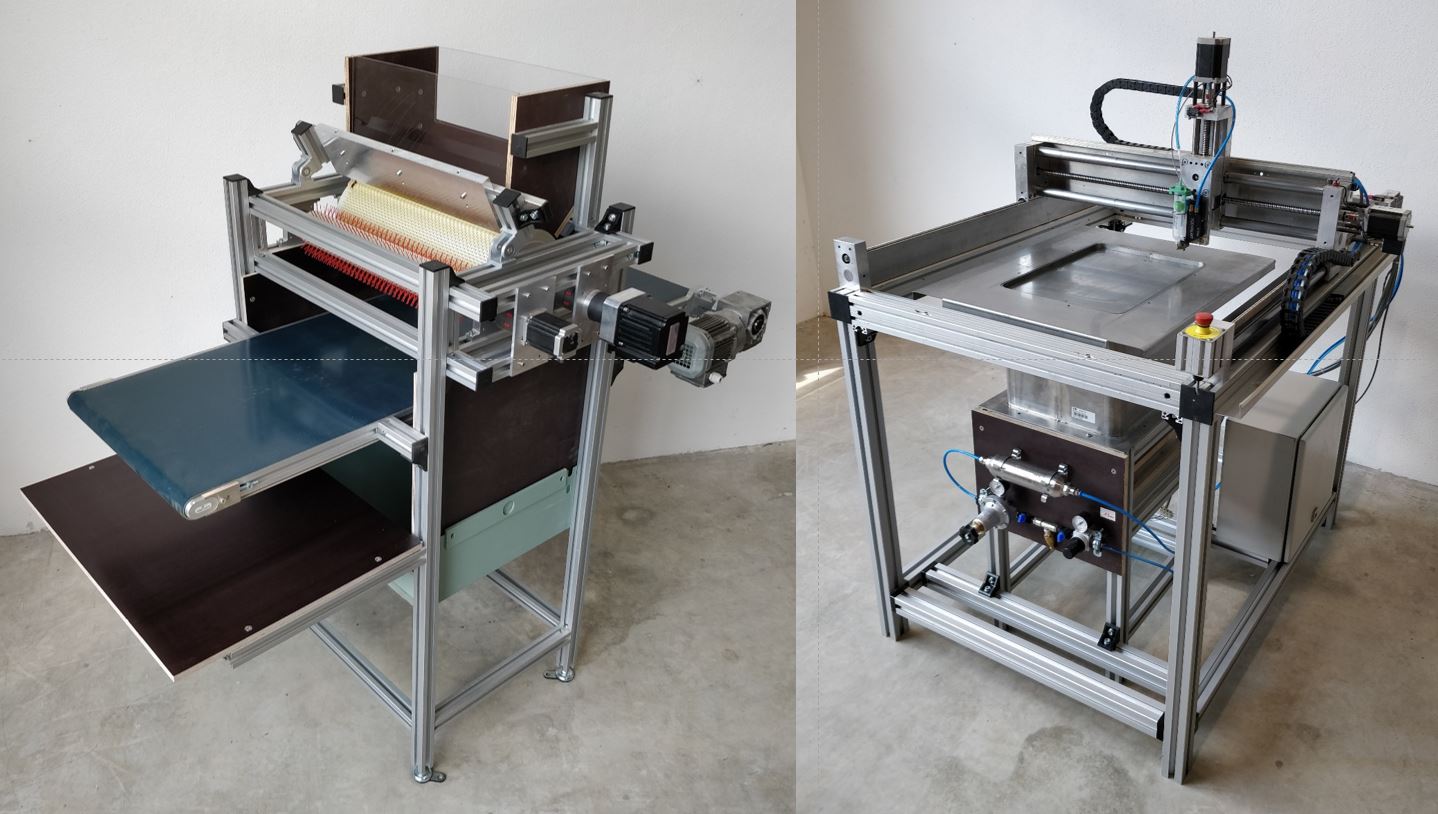

The core idea of ILF is to integrate a work step of mechanical pressing into an additive manufacturing process based on binder jetting technology. Mechanical pressing, rarely applied to additive manufacturing but common practice in the production of conventional wood composite boards, enables the reduction of binder content and an increase of mechanical strength. The integration of pressing is made possible through the individual fabrication of the layers.

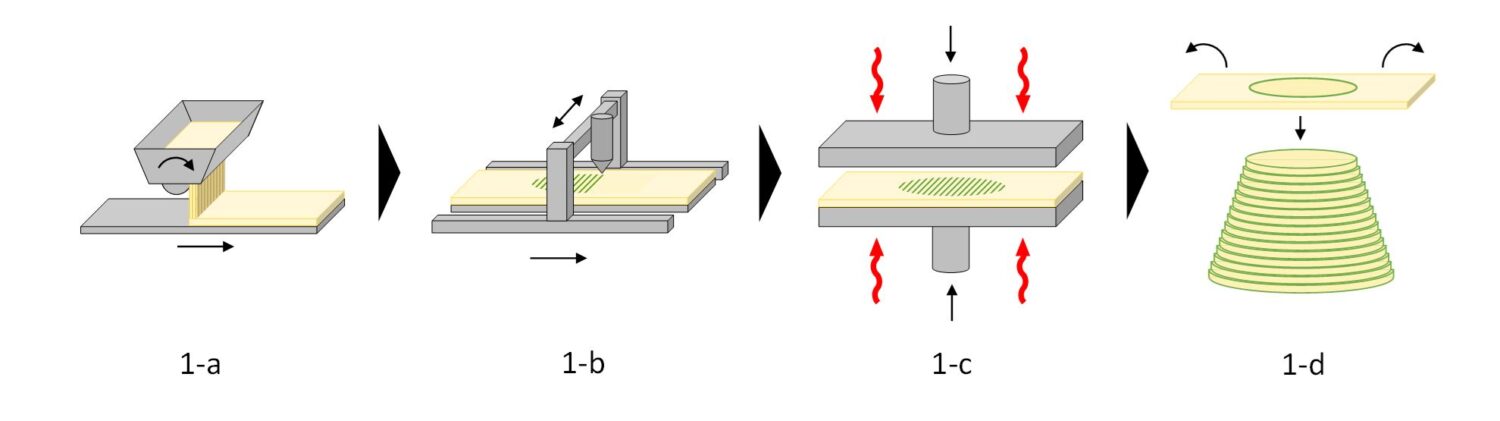

The resulting overall process can be described as a combination of binder jetting and sheet lamination consisting of the following work steps: Particles are spread in a thin layer on a base by a scattering device. A liquid binder is applied locally to this particle bed, limited to those areas that are intended to be bound. The particle binder layer is then pressed and a sheet with bound and unbound bulk material is obtained. Finally, the unbound bulk is removed and the completed panel is transferred and laminated onto the stack of previously fabricated panels. Panel production and lamination are repeated until the desired object is completed.

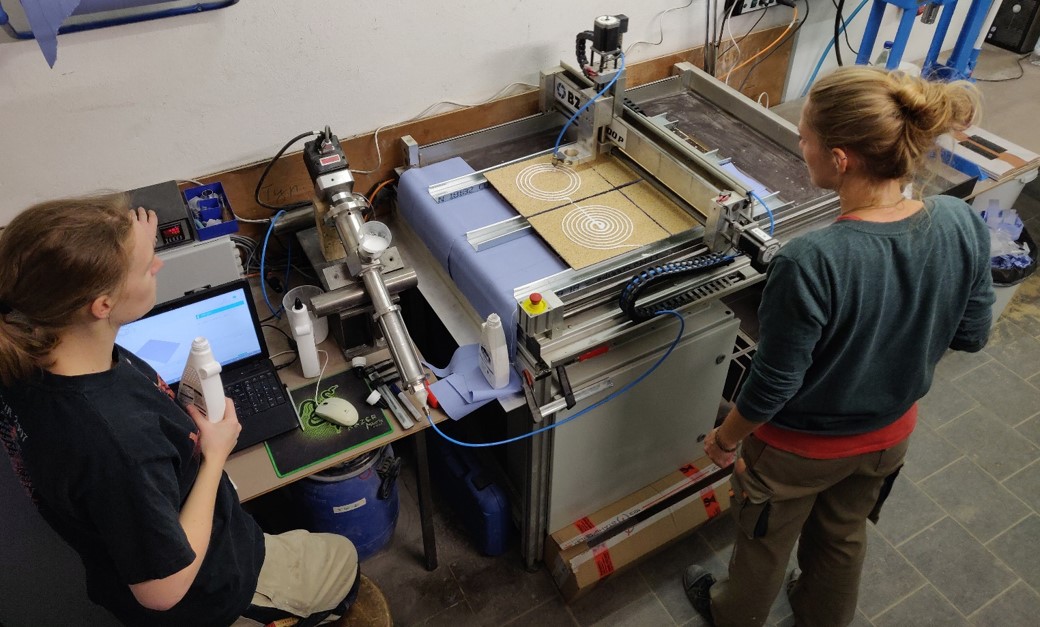

The work program of project A08 is structured into three main work packages. In work package 1 ‘Adhesion systems’ different feedstock materials are investigated to identify wood particles and binders best suited for the process. In work package 2 ‘Process’ devices for the single work steps are developed and combined to form an integrated process. Finally, in work package 3 ‘Applications’ ILF and the parts that can be produced by this process are evaluated concerning their application in the construction industry.

Networking with other projects

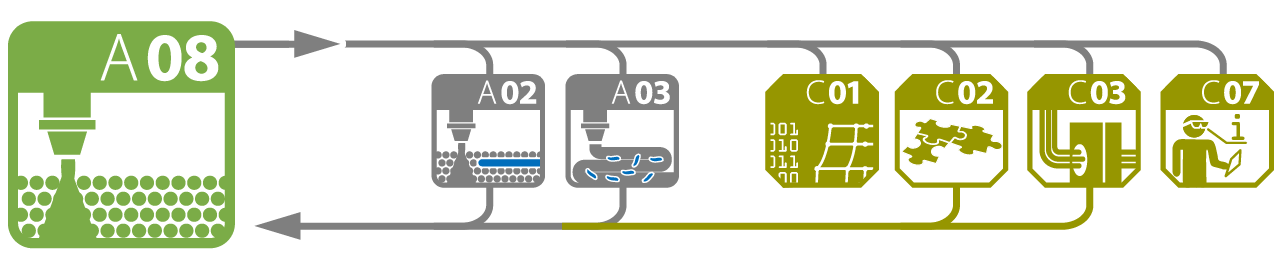

Project A08 is linked to all other projects that apply particle binding processes and particularly to project A02 which uses a similar solution for binder application. Furthermore, it is connected to several C-projects researching questions of design for optimization (project C02) or functional integration (project C03). Finally, there are cooperations with different other projects (A03, A06) working on concepts for large scale joint demonstrators.