Research Summary Report of A08

Structural Timber by Individual Layer Fabrication (ILF)

[09.06.2023]

Buschmann, Birger; Doctoral researcher, birger.buschmann@tum.de,

Talke, Daniel; Doctoral researcher, talke@tum.de

Henke, Klaudius; Project leader, henke@tum.de

Technical University of Munich,

Chair of Timber Structures and Building Construction

Summary

The main goal of the project ‘A08 -Structural Timber by Individual Layer Fabrication (ILF)’ is to develop a process to additively manufacture large-scale, wood composite objects with a maximum content of wood material and strength values suited for applications in construction. In the course of the project multiple process variants and material combinations are explored. For this, the necessary machinery is developed in iterative steps and the mechanical properties of the resulting objects as well as the geometric capacity of the processes are investigated. Finally, multiple demonstrators are fabricated for showcase purposes.

Within A08 the working group Henke is researching the ILF method as a whole and developing a working process chain together with the necessary machinery.

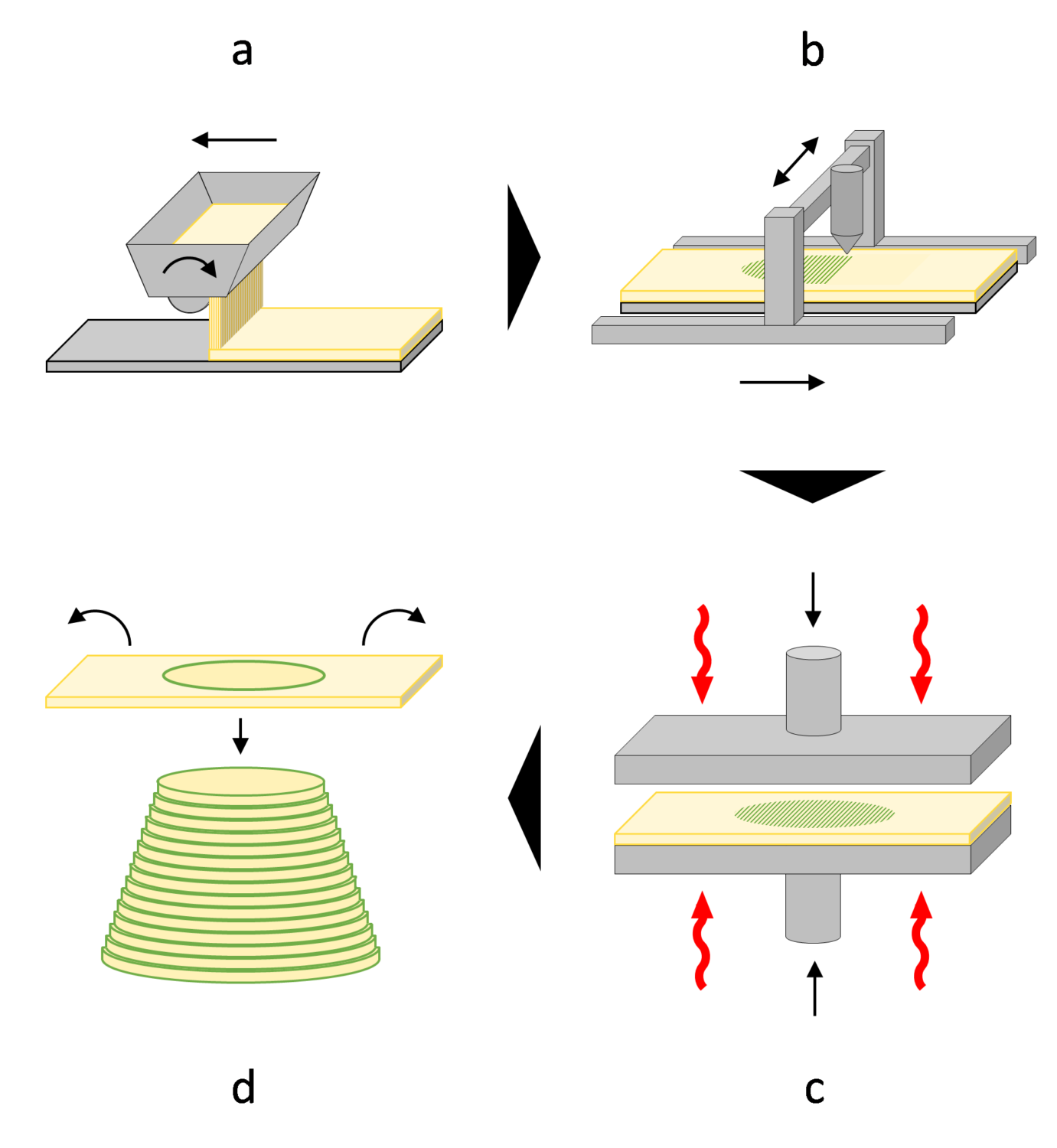

The general scheme of the ILF process is displayed in Figure 2 and can be divided into four main steps. A thin layer of wood particles is scattered (a) and bound by locally dispensing adhesive according to the target geometry of the object (b). After dispensing the adhesive, the wood particle layer is pressed (c). In doing so, the amount of required adhesive is drastically reduced while at the same time the mechanical properties of the wood composite are increased. Finally, the unbound material is removed and the contoured layer of bound material is laminated onto the stack of previously produced layers (d).

For each of these process steps the respective machinery is either developed or acquired and modified if necessary. With the manufacturing of various demonstrators (an example is shown in Figure 1) knowledge is gained about the intricacies of the ILF process and its practical applications. A suitable process parameter framework, geometric limitations and possible improvements are identified.

Current state of research and challenges

The fabrication of the large-scale ILF-Slab demonstrator was the main focus of the last months. The demonstrator has the dimensions of 190 cm x 45 cm x 20 cm and a weight of 30 kg. Most of the machinery for project A08 was finalized for this fabrication. Figure … shows the fabrication steps after the panels were created.

As a modification of the default process described above, for the fabrication of the ILF-slab demonstrator, the unbound particles were not removed immediately after heat pressing. They were rather retained to serve as support material during lamination. Due to the fact, that the unbound particles also gain some solidity by the pressing, the hybrid panels could each be handled easily as one solid piece. By using the 2D geometries of the individual layers to control a gantry system, adhesive was once more applied to these panels). As the panel size is currently limited by the size of the heat press, each layer of the demonstrator had to be composed of several panels. A panel size of 45 cm x 45 cm was chosen and the panels of each second layer were placed with an offset of 22.5 cm resulting in a staggered arrangement (see Figure 3 first). After that they were stacked, laminated and pressed with screw clamps (Fig. 3 second). Only then were the unbound particles removed (Fig. 3 third) to reveal the targeted physical part (Fig. 3 fourth).

Aims for the future

In the second half of year 2023 WG Henke plans to do a study regarding the influence of process parameters on material properties. It was identified that the way adhesive is dispensed and the pressing force both significantly impact the final part properties. This makes it possible to tailor part properties by a controlled variation of process parameters.

Additionally, it is planned to finalize all machinery and process steps in the coming months. With this setup it will then be possible to reliable and consistently produce geometrically complex objects with the ILF-process. The thusly fabricated large-scale objects will then be tested to identify deviations from as-designed properties to as-fabricated properties.