Research Summary Report of C06

Integration of Additive Manufacturing in the Construction Process

[16.06.2023]

Placzek, Gerrit; Doctoral researcher,

g.placzek@tu-braunschweig.de,

TU Braunschweig, IBB

The integration of additive manufacturing into construction requires an interdisciplinary approach. The different competences of the team – digital fabrication in architecture (Hack), geodesy and photogrammetry (Gerke) and construction management (Schwerdtner) – lead to research from diverse perspectives on the various scalar levels of construction to be viewed holistically: component, building and industry scale.

Within Subproject C06, our goal is to create a continuous digital and lean-based process chain from design (using BIM method) to fabrication (using AM method). Based on process models und strategic decisions, we investigate construction processes and how to change them into a construction industry 4.0.

Summary

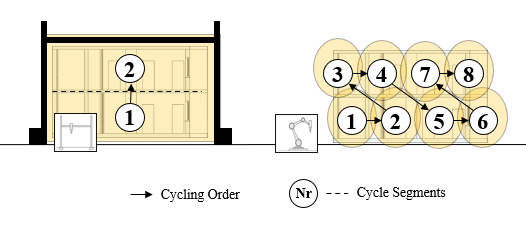

In our latest Research Summary Report (10/22) we introduced four different robotic systems for Extrusion-based in-situ Additive Manufacturing with Concrete. Among these categories, gantry and articulated robots are currently the most prevalent robotic systems in use or under development. Within our latest publication (Placzek/Schwerdtner 2022) we have demonstrated that the design and process-related properties of AR systems significantly affect production planning. This impact was illustrated through the example of construction cycle planning, highlighting how factors such as workspace size, positioning, and the weight and dimensions of the AR systems influence different production strategies.

Considering production planning, the selection of a suitable AR system plays a pivotal role and warrants further in-depth analysis. In future research, it is crucial to conduct quantitative investigations to consider the (rapidly changing) designproperties specific to each manufacturer. This presents a notable challenge in construction-related studies, as it involves the careful selection of AR systems.

Currently, we are intensifying our research in the field of robotic systems and are working together with C04 on the digital planning and positioning of robotic systems.

At the same time, we are working with A04 on a productivity study of the SC3DP process to enable a comparison with conventional formwork-based manufacturing.