Research Summary Report

Research Summary Report A03

Category: Research Summary Report

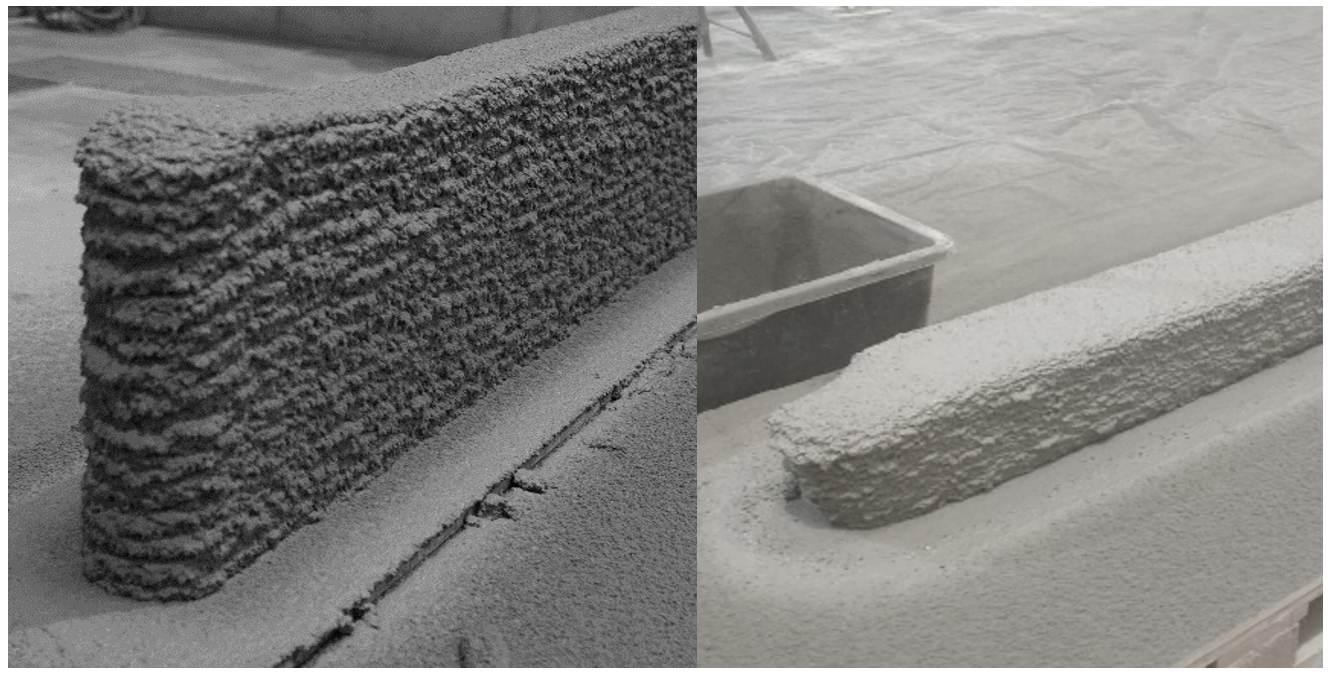

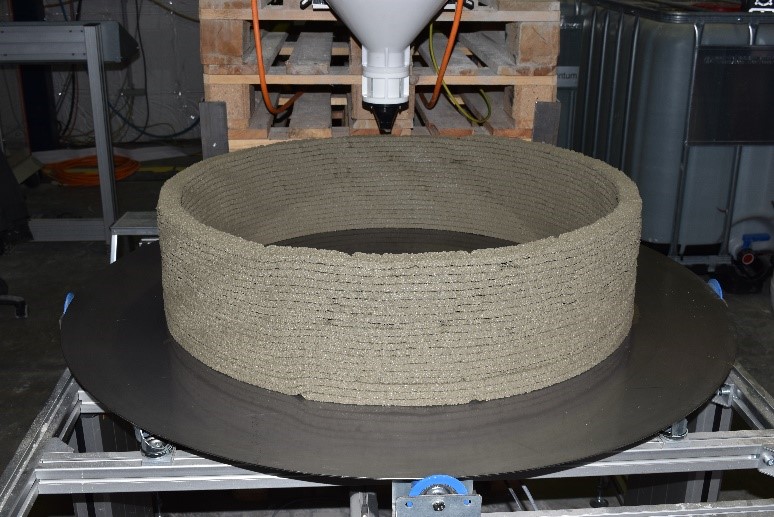

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement [26.08.2022] Hechtl, Christian Maximilian, TP editor, m.hechtl@tum.de, TUM, Chair of Materials Science and Testing (cbm) Dr.-Ing. Matthäus, Carla, TP editor, c.matthaeus@tum.de, TUM, cbm Dr.-Ing. Kränkel, Thomas, PL, thomas.kraenkel@tum.de, TUM, cbm Prof. Dr.-Ing. Gehlen, Christoph, PL, gehlen@tum.de, TUM, cbm The goal of A03 is to establish a concrete extrusion process using a near nozzle mixing approach to enable the change of material properties while printing (gradation). With this approach multifunctional components can be realized. For example, a component can simultaneously fulfill load-bearing and thermal insulation functions by locally changing the material properties. Current state of research The second iteration of the Gradation-ready Extrusion System …

Research Summary Report C01

Category: Research Summary Report

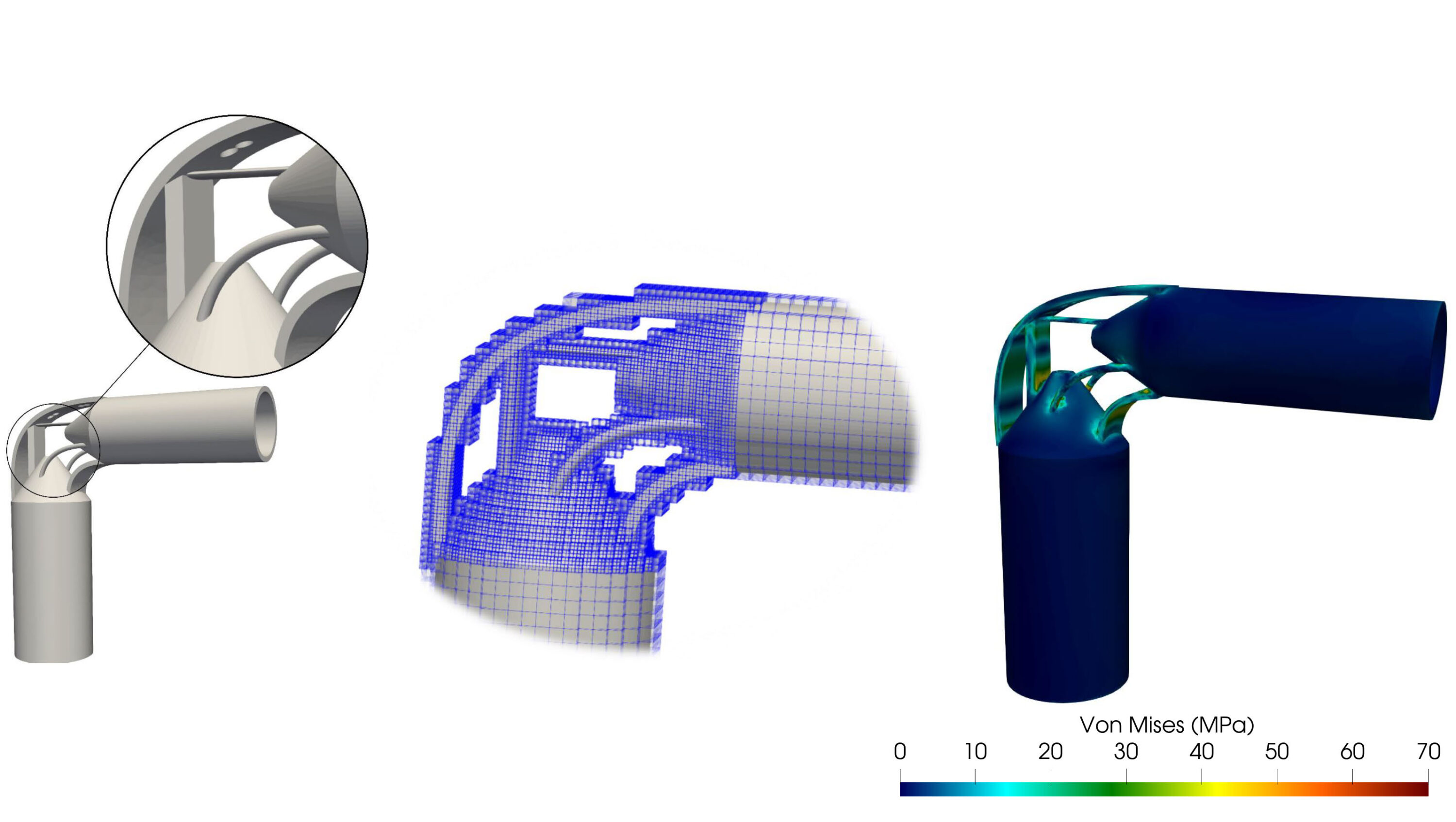

Bridging Scales – From Geometric Part Details to Construction Elements [16.08.2022] Kollmannsberger, Stefan; PL, stefan.kollmannsberger@tum.de, TUM, CMS Rank, Ernst; PL, ernst.rank@tum.de, TUM, Institute for Advanced Study Oztoprak, Oguz; WiMi, oguz.oztoprak@tum.de, TUM, CMS Digital models for Additive Manufacturing (AM) must consider many different geometric scales. The scales range from micrometers up to tens of meters for metal- or concrete-based processes. The TP C01 aims to develop consistent geometric and computational descriptions for the relevant AM products on all of these scales. Based on the multiscale geometric models developed in earlier phases of this research project, we are now focusing on efficient simulation methods for AM products in construction with special emphasis on validation of the developed techniques. Summary The advances …

Research Summary Report B04

Category: Research Summary Report

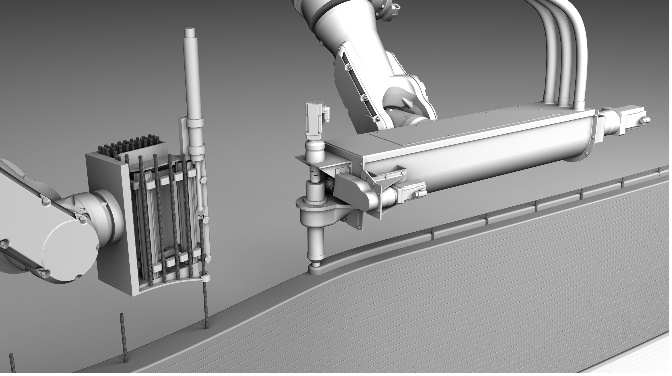

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom [19.08.2022] Lachmayer, Lukas; Doctoral researcher, lachmayer@match.uni-hannover.de Leibniz Universität Hannover, Institute of Assembly Technology (match) Function integration, topology optimization and automation increase productivity through the reduced workload, sustainability by less applied material and safety by decreasing manual labour. These benefits are condensed in most additive manufacturing processes, and thus, these are of significant interest to the construction industry. However, the time- and environment-dependent material properties of fresh concrete reduce the predictability of the material and thus often lead to component collapses during the manufacturing process. This project aims to achieve repeatability within concrete-based robot-guided additive manufacturing processes. Summary As expected and …

Research Summary Report A02

Category: Research Summary Report

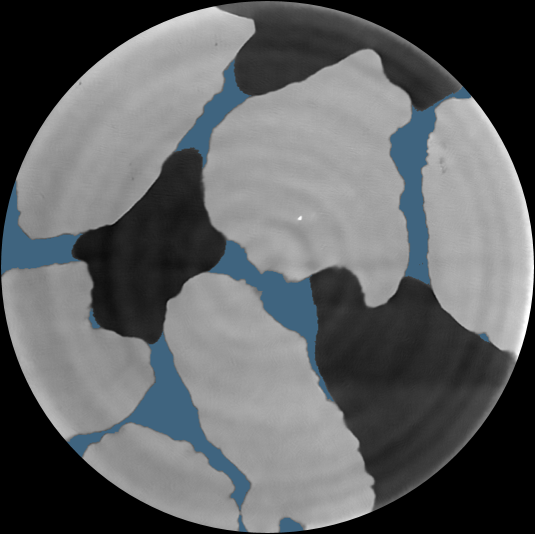

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [09.08.2022] Straßer, Alexander, TP editor, alexander.strasser@tum.de, TUM, Chair of Materials Science and Testing Matthäus, Carla, TP editor, c.matthaeus.@tum.de, TUM, Chair of Materials Science and Testing Kränkel, Thomas, TP editor, thomas.kraenkel@tum.de, TUM, Chair of Materials Science and Testing Gehlen, Christoph, PL, gehlen@tum.de, TUM, Chair of Materials Science and Testing The goal of A02 is to implement reinforcement by Wire and Arc Additive Manufacturing (WAAM) in concrete elements produced by Selective Paste Intrusion (SPI), see Figure 1. Since the cement paste is applied to the aggregates and must penetrate the cavities between the aggregates by gravity, consistent rheological properties of the cement …

Research Summary Report B03

Category: Research Summary Report

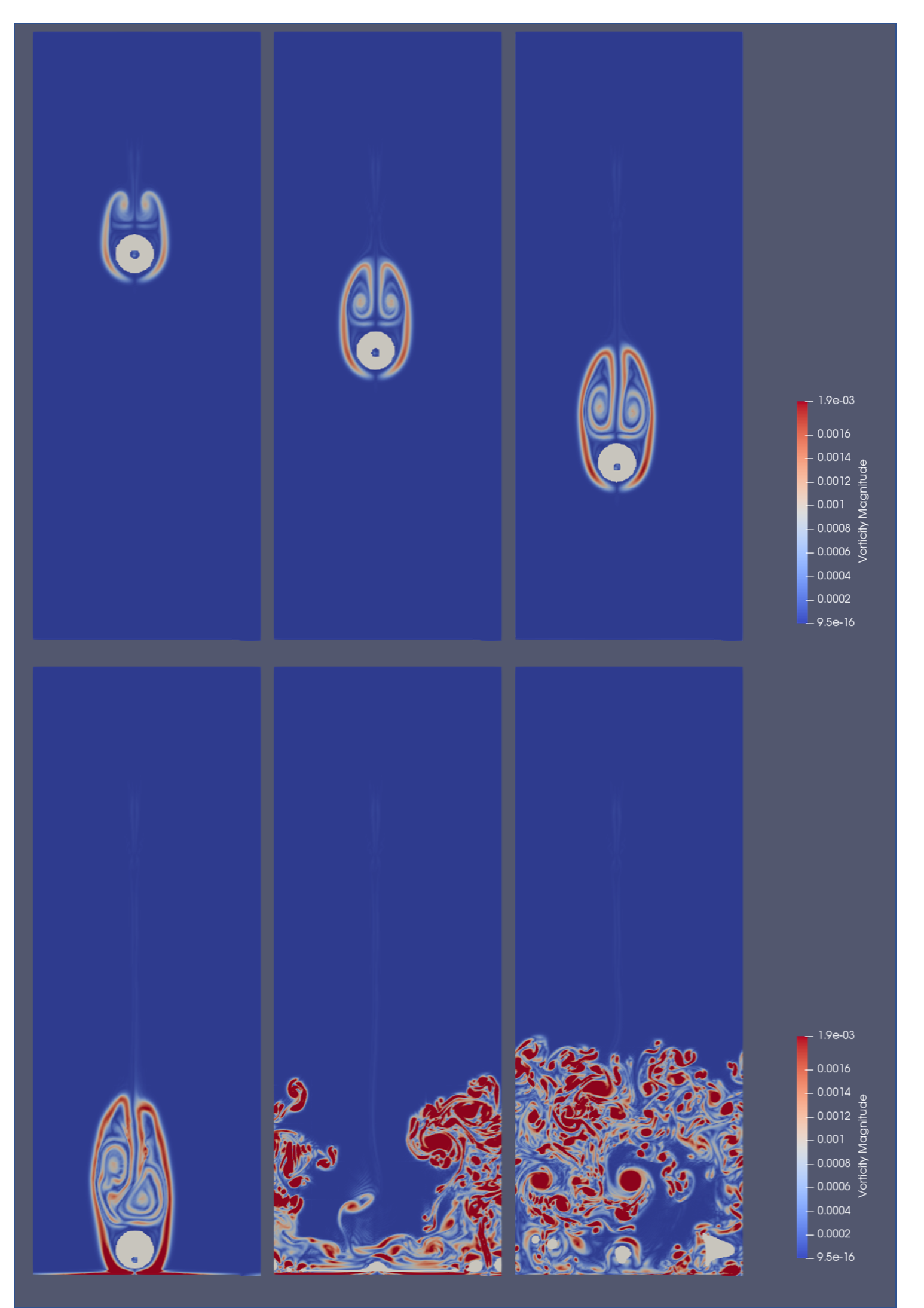

Modelling and Simulation of Shotcrete 3D Printing (SC3DP) Based on a Massively Parallel Multi-Phase, Multi-Component Coupled LBM-DEM Approach [26.07.2022] Kutscher, Konstantin; Researcher Geier, Martin; Project leader Krafczyk, Manfred; Project leader all: TU Braunschweig, Institut für rechnergestützte Modellierung im Bauingenieurwesen (IRMB) B03 goals The primary aim of the project is to understand and quantify the dynamic distribution of material components (fluid, air and particles) and kinetic energy inside the jet of liquid concrete present in the shotcrete process. The information is required as a basis for future optimization of the process with regards to process and material parameters as well as for the prediction of material inhomogeneities. Summary The application of the conservative phase field method to the modeling of droplets …

Research Summary Report A01

Category: Research Summary Report

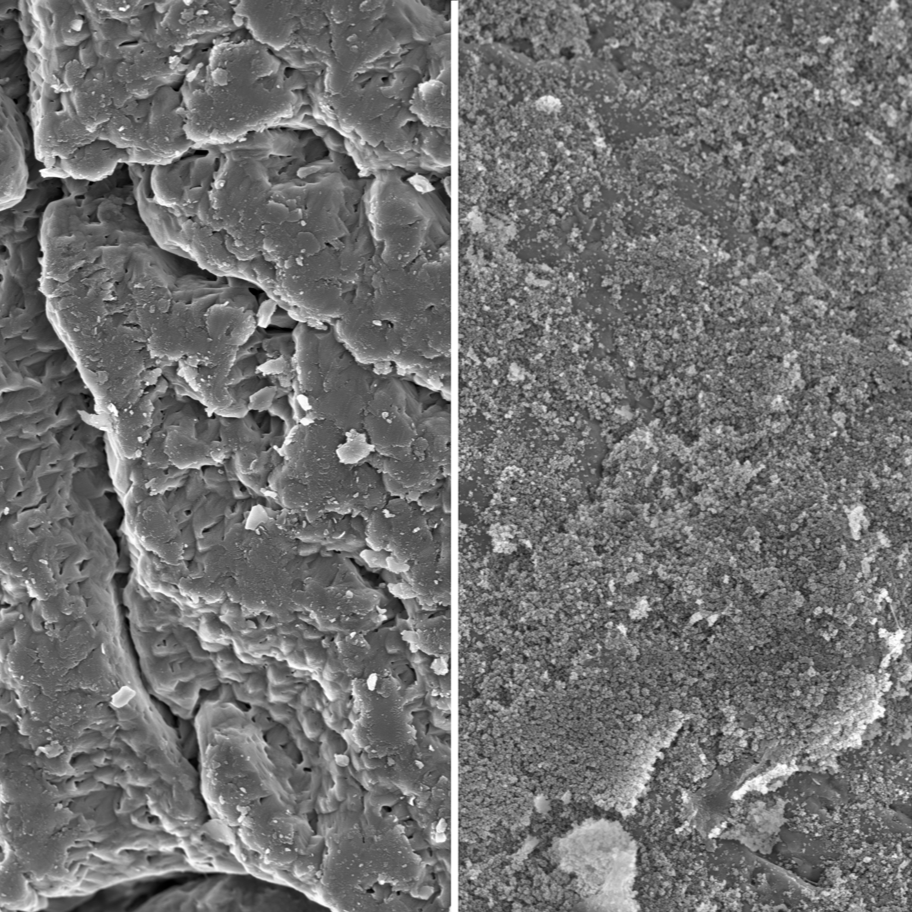

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Particle Surface Functionalisation, Particle-Bed Compaction and Reinforcement Implementation [15.07.2022] Herding, Friedrich; Researcher, f.herding@ibmb.tu-bs.de Mai, Inka; Leading researcher, i.mai@ibmb.tu-bs.de Lowke, Dirk; Project leader, d.lowke@ibmb.tu bs.de all: TU Braunschweig, Institute of Building Materials, Concrete Construction and Fire Safety (iBMB) The main objective of our research in TP A01 is to understand the material-process-interactions in particle bed 3D printing by Selective Cement Activation (SCA) in order to produce concrete elements with high mechanical strength and geometric precision. Besides, we are also investigating different ways of reinforcement integration, which is crucial for the manufacturing of load-bearing building components. Summary In Particle Bed 3D Printing (PB3DP) by Selective Cement Activation the water to cement ratio (w/c‑ratio) …

Research Summary Report C05

Category: Research Summary Report

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes [12.07.2022] The Technical University of Braunschweig, Institute of Structural Design (ITE) Prof. Dr. Harald Kloft.eng (ITE) Prof. Dr. Martin Empelmann.eng (iBMB) Author: Abtin Baghdadi a.baghdadi@tu-braunschweig.de Researchers: Jan-Paul Lanwer, Hendrik Weigel (iBMB), Abtin Baghdadi (ITE) This project, as close cooperation between ITE and iBMB (Concrete-Construction) by subtractive robotic process, aims to investigate the jointing principle to combine different additively manufactured elements. C05 investigates the execution process and load-bearing capacity of the concrete milled dry joints, considering different concrete printing techniques to be utilized in the construction of prefabricated structures. Accordingly, C05 mainly investigates the application of the post-processing grinding technique (milling and cutting) for developing innovative connections and …

Research Summary Report C04

Category: Research Summary Report

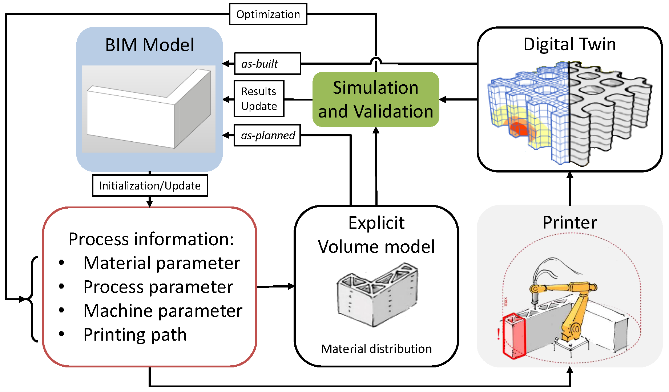

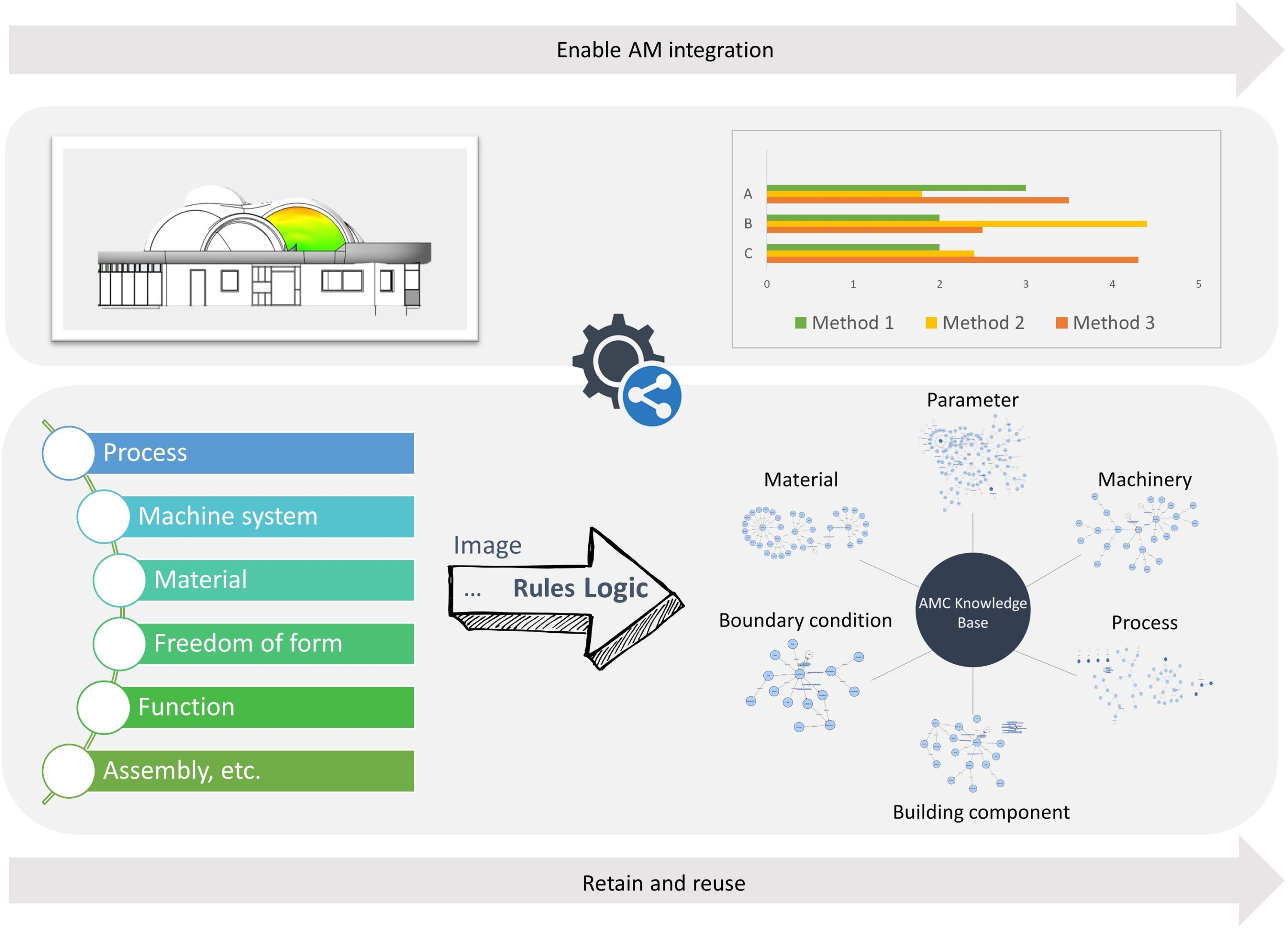

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods [05.07.2022] Borrmann, André, Project leader, andre.borrmann@tum.de, Technical University of Munich, Chair of Computational Modeling and Simulation; Slepicka, Martin, Researcher, martin.slepicka@tum.de, Technical University of Munich, Chair of Computational Modeling and Simulation; Computer Aided Manufacturing (CAM) methods, such as Additive Manufacturing (AM), are becoming increasingly popular in the construction industry, since they offer more geometrical freedom than conventional methods. However, more complex data preparation is required for these methods and thus they have been considered separately from digital design so far. To increase the usefulness of AM for the industry, this project aims to integrate AM methods into the digital design methodology BIM. To achieve this, a framework …

Research Summary Report A05

Category: Research Summary Report

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete [10.06.2022] Rothe, Tom; Doctoral researcher, t.rothe@tu-braunschweig.de, TU Braunschweig, Institute for Mechanics and Adaptronics (IMA) Prof. Hühne, Christian; Project Leader, Christian.Huehne@tu-braunschweig.de, TU Braunschweig, Institute for Mechanics and Adaptronics (IMA) The individual integration of fibre reinforcement into large concrete components produced by Additive Manufacturing (AM) allows new design freedoms and reduces concrete consumption due to the lower cover height. The project A05 develops strategies to integrate freely formable reinforcement strands for the different AM processes of the AMC. For doing so, a Dynamic Winding Machine is developed and constantly updated. Thus, fibre strands can be adapted for different purposes and enables more efficient and easier production of highly customised, reinforced concrete …

Research Summary Report A02

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [17.06.2022] Hamilton, Leigh Duncan; Researcher; Leigh-Duncan.Hamilton@tu-braunschweig.de Zetzener, Harald; Leading researcher; H.Zetzener@tu-braunschweig.de Kwade, Arno; Project leader; A.Kwade@tu-braunschweig.de TU Braunschweig, Institute for Particle Technology Our research mission for A02 is the implementation of Wire and Arc Additive Manufacturing (WAAM) as a means of simultaneously printing the reinforcement during the particle bed concrete 3D-printing method selective paste intrusion (SPI). The combination of SPI and WAAM is accompanied by obstacles that must be overcome in order to ensure collaborated functionality. One major challenge occurs from the propagated thermal load of WAAM (approx. 1600 °C), which has negative effects on the paste rheology and resulting …

Research Summary Report A06

Category: Research Summary Report

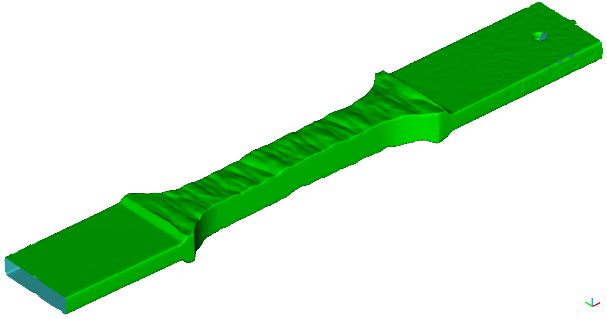

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience [03.06.2022] Wenzler, David; Doctoral researcher; david.wenzler@tum.de Technical University of Munich, Institute for Machine Tools and Industrial Management Diller, Johannes; Doctoral researcher; johannes.diller@tum.de, Siebert, Dorina; Doctoral researcher; dorina.siebert@tum.de Technical University of Munich, Chair of Metal Structures The project A06 aims to explore and evaluate the factors influencing the manufacturing of safe and durable structural steel elements by Powder Bed Fusion of Metals using a Laser Beam (PBF-LB/M). Thereby, the PBF-LB/M process, the post-treatment, and the geometrical aspects in terms of microstructure and mechanical properties will be investigated and correlations will be determined. In the first funding period, the project is focused on analyzing small-scale …

Research Summary Report A04

Category: Research Summary Report

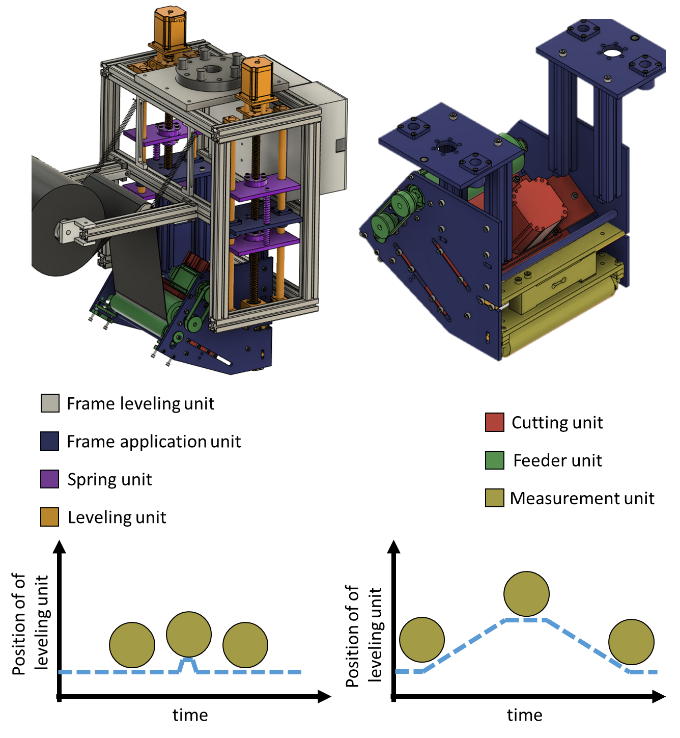

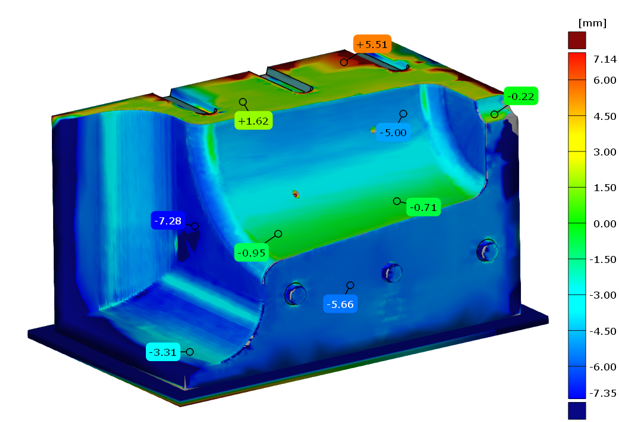

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [25.05.2022] David, Martin; Doctoral Researcher, m.david@tu-braunschweig.de TU Braunschweig, Institute for Machine Tools and Production Technology (IWF) Project A04 aims to investigate cooperative Additive Manufacturing (AM) processes based on Shotcrete 3D Printing (SC3DP) for the production of material-efficient, force-optimized, reinforced, load-bearing concrete components with precise surface quality and geometrical precision. The goal is to produce large-scale concrete elements using significantly lower amounts of reinforcement and concrete as compared to standard concrete construction principles. Hereby, different robot guided end effectors are used for flexible and automated processes. Summary Within SC3DP many process parameters, like volume of sprayed concrete, air volume flow, nozzle to strand distance and …

Research Summary Report A07

Category: Research Summary Report

Wire and Arc Additive Manufacturing (WAAM) of complex individualized steel components [20.05.2022] Jahns, Hendrik; Doctoral researcher Unglaub, Julian, Senior researcher Institute of Steel Structures, Technische Universität Braunschweig In project A07 the design, manufacturing and mechanical performence of complex individualized WAAM steel nodes for use in construction is investigated. A new method is developed to design force flow optimized steel nodes as connectors between semi-finished parts and anchorage structures considering the manufacturing possibilities of the WAAM-process and the resulting material behaviour. The manufacturing possibilities will be identified by case study demonstrators, which represent occurring features of the designed node. The produced parts are characterized regarding their mechanical properties. For that an advanced material testing method was developed to evaluate the potentially …

Research Summary Report A08

Category: Research Summary Report

Structural Timber by Individual Layer Fabrication (ILF) [13.05.2022] Asshoff, Carsten; Doctoral researcher;carsten.asshoff@wki.fraunhofer.de Fraunhofer Institute for Wood Research Wilhelm-Klauditz-Institut WKI The main goal of the project ’A08 – Structural Timber by Individual Layer Fabrication (ILF)’ is to develop a process to additively manufacture large-scale, wood composite objects with a maximum content of wood material and strength values suited for applications in construction. In the course of the project multiple process variants and material combinations are explored. For this, the necessary machinery is developed in iterative steps and the mechanical properties of the resulting objects as well as the geometric capacity of the processes are investigated. Finally, multiple demonstrators are fabricated for showcase purposes. Summary Working group Bunzel is researching the process …

Research Summary Report B04

Category: Research Summary Report

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom [06.05.2022] Ekanayaka, Virama; Doctoral researcher, v.ekanayaka@tu-braunschweig.de TU Braunschweig, Institute of Machine Tools and Production Technology (IWF) Hürkamp, André; Project Leader, a.huerkamp@tu-braunschweig.de TU Braunschweig, Institute of Machine Tools and Production Technology (IWF) The integration of robot-guided additive manufacturing in the construction industry increases the degree of automation and can thus lead to an increased productivity and increased component quality. In shotcrete 3D printing (SC3DP), reproducible manufacturing results and ensuring component qualities are a major challenge, as the properties of shotcrete depend on many different parameters (e.g. temperature, pressure, water-cement ratio, hardening accelerator). The goal of this research project is to …

Research Summary Report C06

Category: Research Summary Report

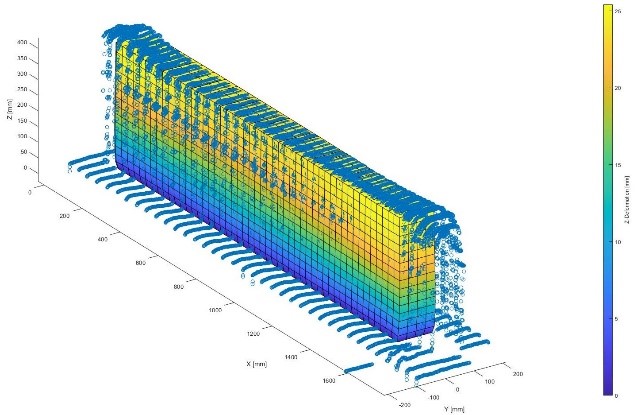

Integration of Additive Manufacturing in the Construction Process [29.04.2022] Mawas, Karam; Doctoral researcher Gerke, Markus; Project leader Maboudi, Mehdi; Associated scientist Riedel, Björn; Associated scientist all: TU Braunschweig, Institute of Geodesy and Photogrammetry (IGP) In order to ensure a robust process is followed and the printed object adheres faithfully to the designed model, continuous and automatic data capturing and inspection of the process is required. As a result, quality control would ensure the original vision of the designer comes to light and that the combination of components into objects actually would work. Summary Digital fabrication is a design and manufacturing workflow where digital data directly drives manufacturing equipment to form various part of geometries on demands using digital data. …

Research Summary Report A07

Category: Research Summary Report

Wire and Arc Additive Manufacturing (WAAM) of complex individualized steel components [22.04.2022] Müller, Christoph; doctoral researcher, TU Braunschweig, Institute for Structural Design (ITE) The aim of TP A07 is the design, the manufacturing and the testing of complex individualized steel components by means of WAAM. That contains the fundamental investigation of design and the design process for WAAM components. For the manufacturing of steel components by WAAM, stable and reliable processes for basic geometries are qualified and based on that, case study demonstrators for the identification of manufacturing restrains are fabricated. Furthermore a novel approach for material and component testing is developed to identify local material and component properties. Summary In the regularly published literature on additive manufacturing, the fabrication …

Research Summary Report A01

Category: Research Summary Report

Particle-bed 3D printing by selective cement activation: Particle surface functionalization, particle bed compaction and reinforcement [12.04.2022] Authors: Meier, Niklas; Researcher, Zetzener, Harald; Leading researcher, Kwade, Arno; Project Leader, all: TU Braunschweig, Institute for particle technology The main goal of our research at A01 is to improve the mechanical strength and shape accuracy of the printed concrete parts as well as the printing speed. While the project partner iBMB focuses on the material-process interaction, the work packages performed at the iPAT are targeted at improving the powder properties. Summary To reach higher mechanical strengths, one approach is to increase the packing density of the powder and therefore the density of the final part. Therefore the particle surfaces are modified, for …

Research Summary Report A03

Category: Research Summary Report

Extrusion of Near-Nozzle Mixed Concrete – Individually Graded in Density and in Rate of 3D Fibre Reinforcement [15.04.2022] Authors: Dahlenburg, Maximilian; Researcher Fottner, Johannes; Project Leader all: TUM, Chair of Materials Handling, Material Flow, Logistics A03 has the main goal to make graded concrete extrusion possible. Therefor an innovative near-nozzle-mixing system is being developed, optimized, and tested. Summary The evolution of 3D-concrete printing is advancing at a fast pace worldwide due to the great potential of these technologies regarding time-, resource efficiency and sustainability. This project focuses on enabling graded concrete extrusion by manipulating material properties in-situ. Furthermore, it targets to handle general additive manufacturing (AM) problems with concrete regarding limitations in the material design. In state-of-the-art concrete printers material …

Research Summary Report C04

Category: Research Summary Report

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods [25.03.2022] Li, Chao; doctoral researcher, chao1.li@tum.de Petzold, Frank; PL, petzold@tum.de Technical University of Munich, TUM School of Engineering and Design, Chair of Architectural Informatics The application of Additive Manufacturing (AM) methods in the construction process requires the careful consideration of its applicability and the necessary boundary conditions in the early design phase of construction. Project C04-WP1 aims to conceive a design decision support system (DDSS) to integrate AM technologies in the early design phase. The DDSS allows the analysis of the early-stage building design regarding the geometric features and functional properties of the individual components and provide recommendations for the manufacturing method. Summary Consideration of …