Research Summary Report A01

Particle-bed 3D printing by selective cement activation: Particle surface functionalization, particle bed compaction and reinforcement

[12.04.2022]

Meier, Niklas; Researcher,

Zetzener, Harald; Leading researcher,

Kwade, Arno; Project Leader,

all: TU Braunschweig, Institute for particle technology

The main goal of our research at A01 is to improve the mechanical strength and shape accuracy of the printed concrete parts as well as the printing speed. While the project partner iBMB focuses on the material-process interaction, the work packages performed at the iPAT are targeted at improving the powder properties.

Summary

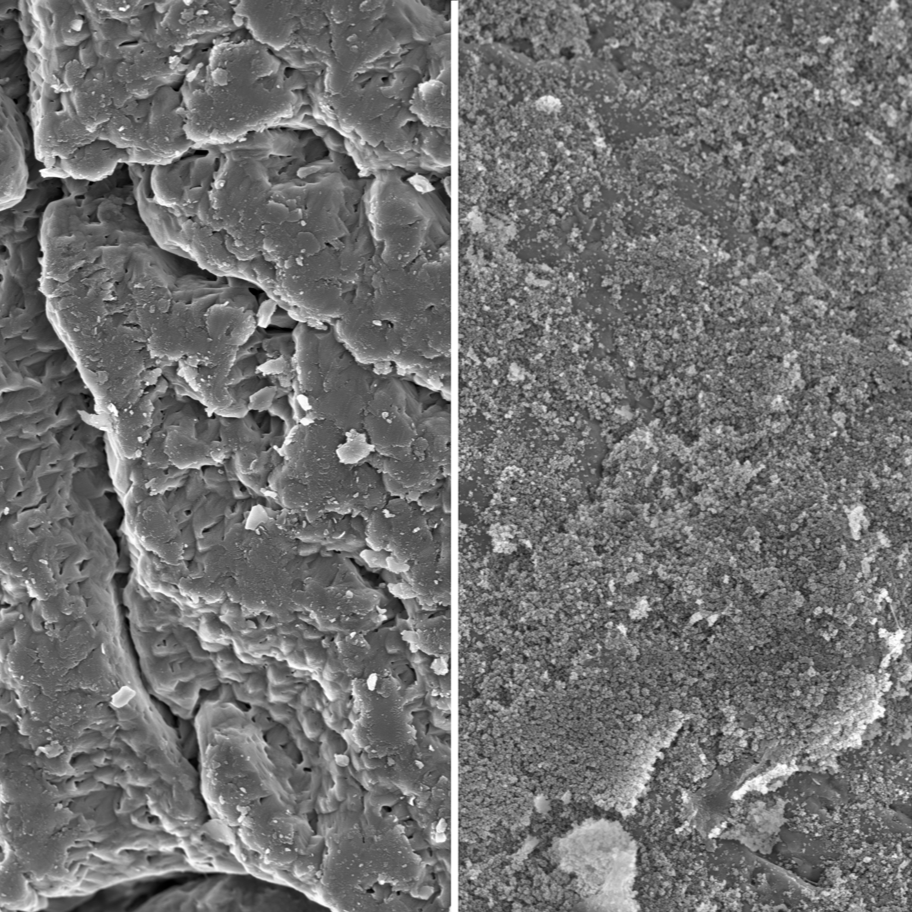

To reach higher mechanical strengths, one approach is to increase the packing density of the powder and therefore the density of the final part. Therefore the particle surfaces are modified, for example with nanoparticles (Figure 1) or liquid additives, to increase the flowability of the sand cement mixture and with it the packing density. To make the advantages of surface modifications available for an actual printing process, the techniques for modifying the particle surfaces need to be scaled up. Therefore, various sizes and types of mixing devices are used to investigate the influence of process parameters on the surface modifications. Additionally, the particle size distribution of the powder is part of the research. One goal is to reach higher packing densities due to a tailored particle size distribution of the sand cement mixture. Another goal is to reduce the necessary cement content, while keeping the strength constant. Furthermore, the spreading and compaction process is investigated, since it has a major influence of the packing density of the powder in the printer.

Current state of research

The above mentioned surface modification techniques gave promising results, regarding the packing density, the flowability ffC, measured with a ring shear tester as seen in Figure 2, and the compressive strength. To better understand the reasons leading to these improvements, experiments are carried out, taking a deeper look onto the surface properties of the modified powders, e.g. inverse gas chromatography is used to measure the surface energy of the powder. This should give hints on the adhesive forces between single particles.

Furthermore, additional research is needed to investigate, if the higher strength of printed specimen is caused by the higher packing density alone, since other aspects like the hydration of the cement could be a reason for this observation, too.

Figure 1: SEM images (mag.: 20,000) of an uncoated (left) and a coated (right) aggregate particle. Credit: iPAT, TU Braunschweig

Figure 2: Ring shear tester. Credit: iPAT, TU Braunschweig