News

Research Summary Report of A04

Category: Research Summary Report

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [23.02.2024] Dörrie, Robin Phd candidate r.doerrie@tu-braunschweig.de Technische Universität Braunschweig ITE Institut für Tragwerksentwurf Main Goal The project aims to fundamentally understand SC3DP technology to manufacture sustainable, multi-objective optimised, reinforced concrete components with precise surface quality and improved building physics via functional integration. It seeks to minimise carbon footprint by exploring varied material strategies, such as reducing cement content and design methods to decrease overall concrete volume. Additionally, it focuses on establishing reliable material and process control, emphasising fresh material laws for printability and durability, real-time monitoring of concrete properties, and component build-up strategies. Integration of large-scale reinforcement enhances structural suitability, while precise surface finishing …

Research Summary Report of B04

Category: Research Summary Report

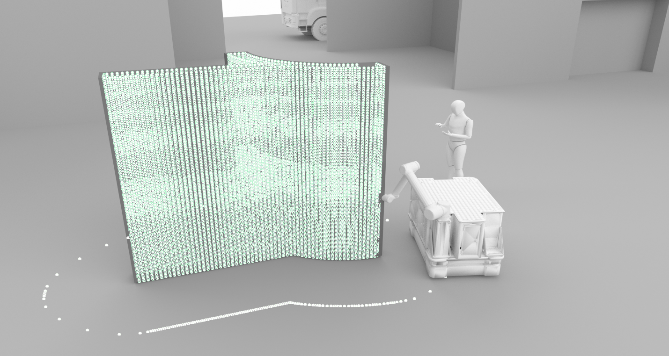

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom [07.02.2024] Raatz, Annika; raatz@match.uni-hannover.de LUH, Institute of Assembly Technology and Robotics Lachmayer, Lukas; lachmayer@match.uni-hannover.de LUH, Institute of Assembly Technology and Robotics Heeren, Hauke; heeren@match.uni-hannover.de LUH, Institute of Assembly Technology and Robotics Main Goal The research of project B04 is dedicated to extending the current state-of-the-art path planning and process control algorithms for concrete-based additive manufacturing. The objective is to enable reproducible production of multi-material components utilizing mobile robot systems in motion, known as print-while-driving. Achieving this requires precise localization, considering system dynamics, such as acceleration and jerk limitations, as well as accounting for varying material properties and building installation …

Research Summary Report of C01

Category: Research Summary Report

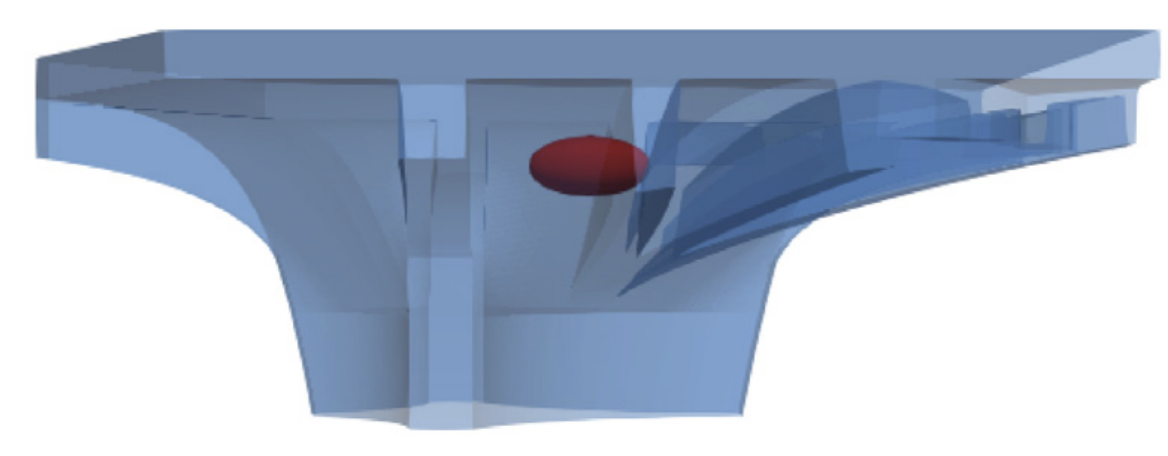

Bridging Scales – From Geometric Part Details to Construction Elements [02.02.2024] Kollmannsberger, Stefan; stefan.kollmannsberger@tum.de TUM, Computational Modeling and Simulation Bürchner, Tim; tim.buerchner@tum.de TUM, Computational Modeling and Simulation Rank, Ernst; ernst.rank@tum.de TUM, Institute for Advanced Study Digital models for Additive Manufacturing (AM) must consider many different geometric scales. The scales range from micrometers up to tens of meters for metal- or concrete-based processes and mutually influence each other. Project C01 aims to develop consistent geometric and computational descriptions for the relevant AM products on all these scales. As-built structures naturally deviate from as-designed structures in geometry, topology, and material properties especially in additive manufacturing. The consequences of such deviations upon the structural behaviour are commonly termed the effect of defect. …

Research Summary Report of A03

Category: Research Summary Report

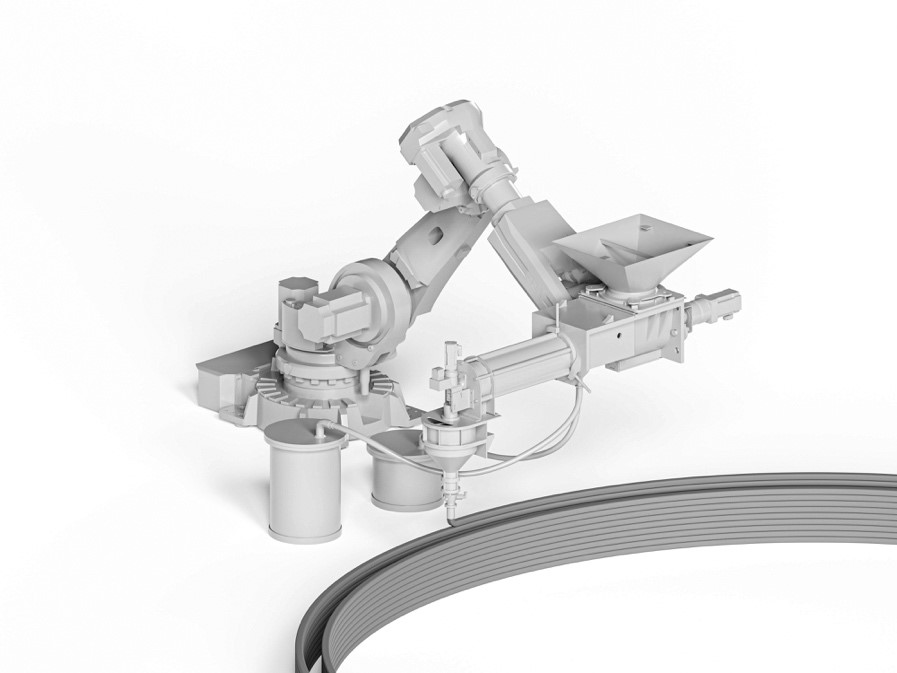

Extrusion of Near-Nozzle Mixed Concrete – Individually Graded in Density and in Rate of 3D Fibre Reinforcement [1.12.2023] Hechtl, Christian Maximilian, TP editor, m.hechtl@tum.de, TUM, cbm Dr.-Ing. Kränkel, Thomas, PL, thomas.kraenkel@tum.de, TUM, cbm Prof. Dr.-Ing. Gehlen, Christoph, PL, gehlen@tum.de, TUM, cbm The goal of A03 is to establish a concrete extrusion process using a near nozzle mixing (NNM) approach to enable the gradual variation of material properties during printing (gradation). This approach allows for the creation of multifunctional components, such as structures merging both load bearing and thermally insulating zones, by precisely altering material properties as required throughout the printing process. Summary and Current State of Research GRES V1 is a gradation-ready extrusion system that demonstrates the potential …

The AMC at parliamentary evening in Berlin

Future Mobility Under the motto ‘Future Mobility – autonomous and digital,’ the city of Braunschweig, along with TU Braunschweig, presents itself to the capital’s politics and press. Bundled in one evening, participants get to know, among other things, the connection between a functioning infrastructure and a digital and 3D-printed construction industry. More information at TUBraunschweig -future mobility About TRR 277 AMC: The Collaborative Research Center TRR 277 Additive Manufacturing in Construction (AMC) is dedicated to advancing research in the field of construction, with a focus on leveraging 3D printing technology to revolutionize sustainable and energy-efficient building practices. Through innovation and collaboration, the center aims to usher in a new era for the construction industry. In the interdisciplinary, cross-location and …

Research Summary Report of A02

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [17.11.2023] Straßer, Alexander, TP editor, alexander.strasser@tum.de, TUM, Chair of Materials Science and Testing Kränkel, Thomas, TP editor, thomas.kraenkel@tum.de, TUM, Chair of Materials Science and Testing Gehlen, Christoph, PL, gehlen@tum.de, TUM, Chair of Materials Science and Testing The goal of A02 is to implement reinforcement by Wire and Arc Additive Manufacturing (WAAM) in concrete elements produced by Selective Paste Intrusion (SPI), see Figure 1. Since the cement paste is applied to the aggregates and must penetrate the cavities between the aggregates by gravity, consistent rheological properties of the cement paste are essential. The welding process with WAAM generates high temperatures …

A New Era for Sustainable Construction

AMC Enters Second Funding Phase The collaborative project “Additive Manufacturing in Construction” (AMC), explores new perspectives for the construction industry. Research on 3D printing in construction at the Technical University of Braunschweig and the Technical University of Munich receives four more years of funding from the German Research Foundation (DFG). 3D printing methods for building with clay and flood protection Challenges in Traditional Construction: Conventional construction processes are characterized by inefficient material usage, high environmental impact, and stagnant productivity. With a growing global population and an increasing demand for housing, the construction industry is reaching its limits. Faced with these challenges and the global significance of the construction sector as a major contributor to CO2 emissions with substantial resource …

Research Summary Report of B03

Category: Research Summary Report

Modelling and Simulation of Shotcrete 3D Printing (SC3DP) Based on a Massively Parallel Multi-Phase, Multi-Component Coupled LBM-DEM Approach [10.11.2023] Kutscher (PostDoc), M. Geier (PI), M. Krafczyk (PI) TU Braunschweig, IRMB The primary aim of the project is to understand and quantify the dynamic distribution of material components (fluid, air and particles) and kinetic energy inside the jet of liquid concrete present in the shotcrete process. The information is required as a basis for future optimization of the process with regards to process and material parameters as well as for the prediction of material inhomogeneities. Summary In order to overcome the numerical difficulties arising from sustaining a high-density ratio in the diffuse interface lattice Boltzmann model we developed a new …

Research Highlights of the 1st funding period (2020-2023)

Take a look at all the highlights of the TRR 277 AMC projects. The videos show the project and their achievements of the entire first four years at a glance. In short presentations you will learn about the main findings, collaborations and gain an overview of the publications and the people behind the projects. This overview was produced at the last AMC Conference in October 2023. The AMC Conference focused on the future of construction with 3D printing technologies. Researchers from the Technical University of Braunschweig and the Technical University of Munich, part of TRR 277 AMC, aim to make construction more resource-efficient, lower-emission, and economical through innovative 3D printing processes. The conference provided insights into AMC’s research areas, including …

Research Summary Report of A01

Category: Research Summary Report

Particle bed 3D printing by selective cement activation: Particle surface functionalization, particle bed compaction and reinforcement integration [03.11.2023] Herding, Friedrich; Researcher, f.herding@ibmb.tu-bs.de Lowke, Dirk; Project leader, lowke@tum.de TU Braunschweig, Institute of Building Materials, Concrete Construction and Fire Safety / Technical University of Munich, Department of Materials Engineering Our main research objective is the fundamental understanding of the material-process interactions in particle bed 3D printing (PB3DP) by Selective Cement Activation (SCA). This will allow for the manufacturing of concrete elements with high mechanical strength and dimensional accuracy. Besides we also investigate different ways of reinforcement integration, which is crucial for the manufacturing of load-bearing building components. Summary In particle bed 3D printing by Selective Cement Activation, the particle mixture mainly …

Code.Craft.Construct. Navigating the Digital Transformation in Architecture and Construction

Inaugural lecture by Prof. Dr. Norman Hack Code.Craft.Construct. Navigating the Digital Transformation in Architecture and Construction Wednesday, 8. November 2023, 5.00 pm | Pockelsstr. 11, TU Braunschweig, Aula, Haus der Wissenschaft As of today, the computer and the digitally controlled machine have a 70-year history in the architectural discourse. Over the years, the fields of application and the potentials of the computer in architecture have been constantly reinterpreted and implemented, whereby the natural sciences, philosophy and art have always had a significant influence on this discourse. In the inaugural lecture „Code.Craft.Construct. Navigating the Digital Transformation in Architecture and Construction“, Professor Hack gives an overview of the influential developments in the discourse of digital architecture and locates his own research on …

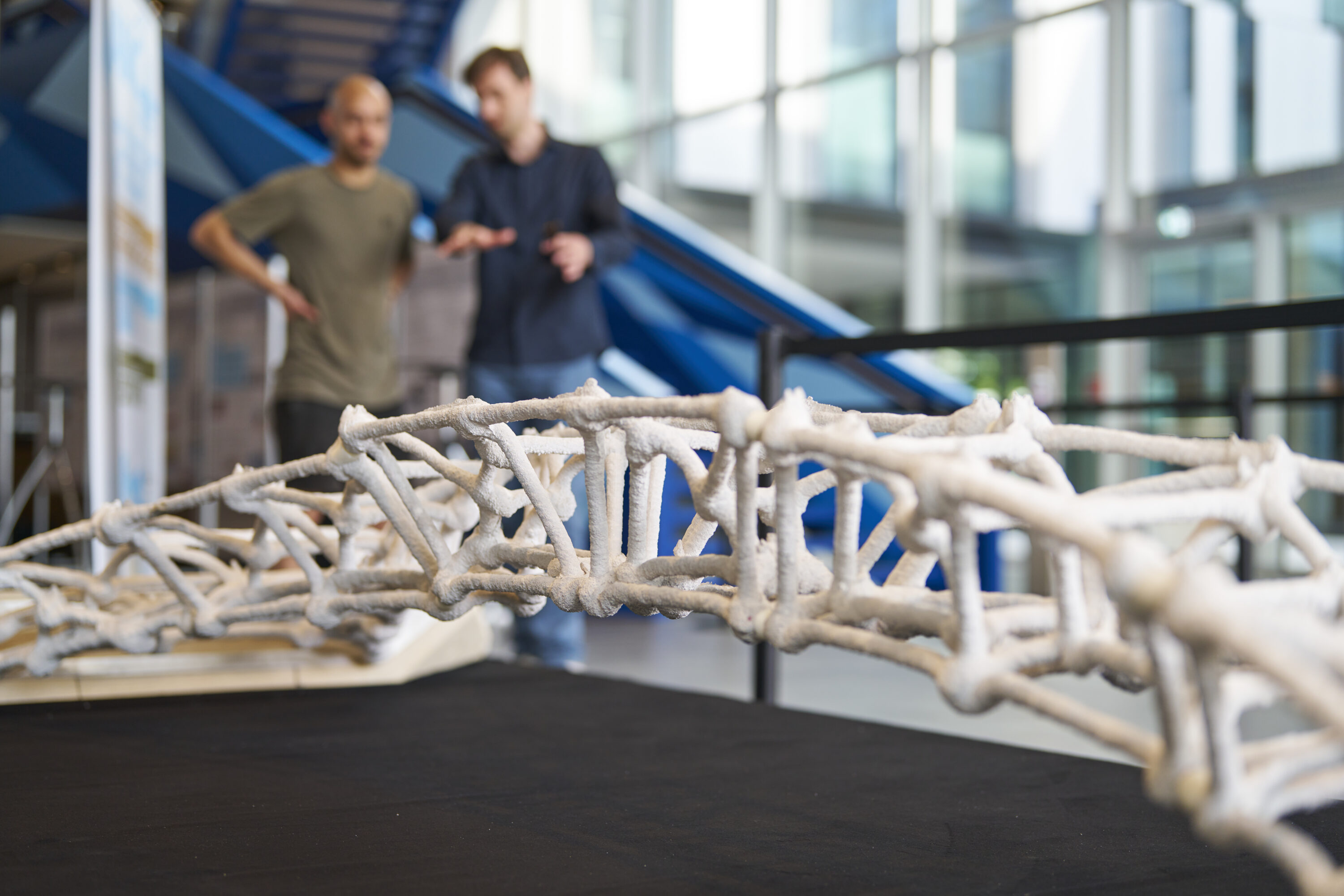

Build with the 3D printer: Stephan Weil visits TU Braunschweig

Buildings are part of our cultural development. New technologies are now needed to make construction more environmentally friendly, faster and more economical. Scientists at the AMC Collaborative Research Centre see additive manufacturing, or 3D printing, as a key digital technology for the construction of the future. On 23 October, the scientists showed Lower Saxony’s Minister President Stephan Weil how they are conducting fundamental research into 3D printing together. “Research from Lower Saxony is a real driver of innovation, as I was once again able to see for myself today at the TU Braunschweig. New technologies are being developed here that make construction more environmentally friendly, faster and more economical – a real milestone,” says Stephan Weil, Minister President of Lower …

Digital Construction – Conference with visionaries for the construction of the future

Instead of brick on brick built by hand, layer by layer 3D printed with a robot. This is what the future of building could look like. The first buildings in Germany are already standing, and the largest printed building in Europe was recently completed in Heidelberg. At the Technical University of Braunschweig and the Technical University of Munich, scientists of TRR 277 AMC are researching new 3D printing processes to make the construction of the future more resource-efficient, lower-emission and more economical. The AMC had now presented its research results. The keynote speaker was Leibniz Prize winner Professor Achim Menges, spokesperson for the IntCDC Cluster of Excellence (Digital Technologies for Design and Construction of the Future) at the University of …

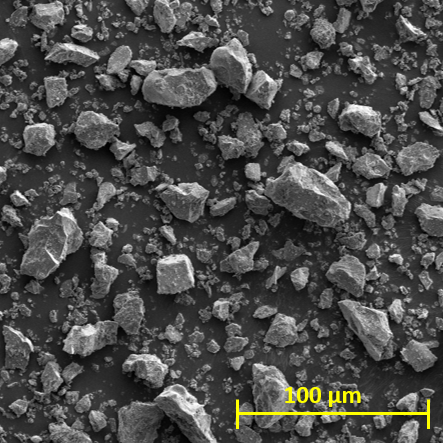

Research Summary Report of A02

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [06.10.2023] Hamilton, Leigh Duncan; Researcher; Leigh-Duncan.Hamilton@tu-braunschweig.de Zetzener, Harald; Leading researcher H.Zetzener@tu-braunschweig.de Kwade, Arno; Project leader A.Kwade@tu-braunschweig.de All: TU Braunschweig, Institute for Particle Technology Our main goal within project A02 is to unite two additive manufacturing (AM) processes, thereby, creating a hybrid AM process for structural concrete. The foundation of A02 is formed around the concrete 3D printing process Selective Paste Intrusion (SPI). SPI creates components in layers by first spreading coarse aggregates (usually quartz) on a surface or previous layer. Subsequently, the cement slurry is applied onto designated areas, where it fills void volumes between aggregate particles. The second …

Research Summary Report of A05

Category: Research Summary Report

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete [29.09.2023] Rothe, Tom; Doctoral researcher, t.rothe@tu-braunschweig.de, TU Braunschweig, Institute of Mechanics and Adaptronics (IMA) Hühne, Christian; Project Leader, Christian.Huehne@tu-braunschweig.de, TU Braunschweig, Institute of Mechanics and Adaptronics (IMA) Fig 2: Robotic integration of reinforcement into the column of the Shelltonics demonstrator The individual integration of fibre reinforcement into large concrete components produced by Additive Manufacturing allows new design freedoms and reduces concrete consumption due to reduced concrete cover. The project A05 develops strategies to integrate freely formable reinforcement strands for the different AM processes. For doing so, a Dynamic Winding Machine is developed and constantly updated. This machine is used to consolidate and impregnate a primary fibre strand …

Research Summary Report of A04

Category: Research Summary Report

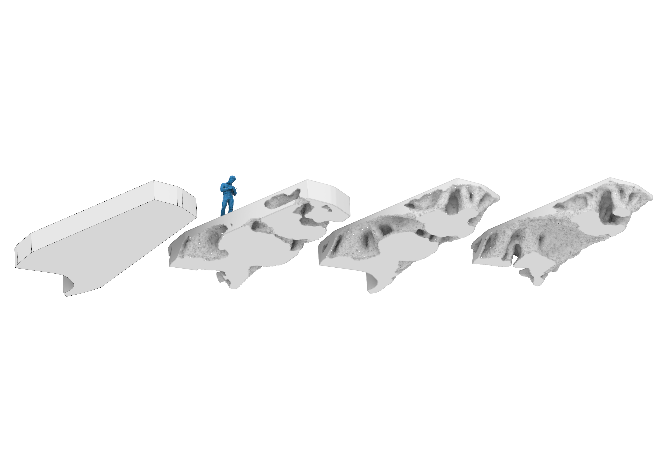

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [30.09.2023] David, Martin; Doctoral Researcher, m.david@tu-braunschweig.de, TU Braunschweig, Institute for Machine Tools and Production Technology (IWF) Summary and Current state of research Project A04 aims to investigate cooperative Additive Manufacturing (AM) processes based on Shotcrete 3D Printing (SC3DP) for the production of material-efficient, force-optimised, reinforced, load-bearing concrete components with precise surface quality and geometrical precision. The goal is to produce large-scale concrete elements using significantly lower amounts of reinforcement and concrete as compared to standard concrete construction principles. Hereby, different robot guided end effectors are subject to research in a flexible and automated process chain. Currently, the following key points are researched by the …

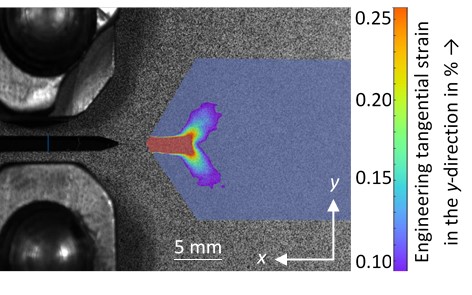

Research Summary Report of A06

Category: Research Summary Report

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience [22.09.2023] Wenzler, David; doctoral researcher; david.wenzler@tum.de Technical University of Munich, Institute for Machine Tools and Industrial Management Diller, Johannes; doctoral researcher; johannes.diller@tum.de, Siebert, Dorina; doctoral researcher; dorina.siebert@tum.de Technical University of Munich, Chair of Metal Structures Project The project A06 aims to explore and evaluate the factors influencing the manufacturing of safe and durable structural steel elements by laser powder-bed fusion (LPBF). Thereby, the LPBF process, the post-treatment, and the influence of the part geometry on the microstructure and the mechanical properties will be investigated. From the results, correlations between these aspects will be determined. In the 1st funding period, the project focuses on …

The Collaborative Research Center TRR 277 pioneers the Future of Construction with 3D Printing

The Collaborative Research Center TRR 277 AMC is excited to announce its upcoming event, the First Funding Period Closing Conference, scheduled to take place from October 9th to 11th, 2023. The conference, held at TU Braunschweig’s Audimax, showcases the remarkable research outcomes from the initial four years of the DFG-funded Transregio project, featuring a keynote speech by Achim Menges. TRR 277 AMC’s research is centered around the future of Digital Building, emphasizing resource-efficient and energy-efficient construction methods enabled by 3D printing technology. This innovative approach not only redefines traditional construction practices but also offers new design freedoms by integrating material, process, and design considerations. Presenting a comprehensive overview of the research accomplishments, the AMC Conference provides an exceptional opportunity for …

Research Summary Report of A07

Category: Research Summary Report

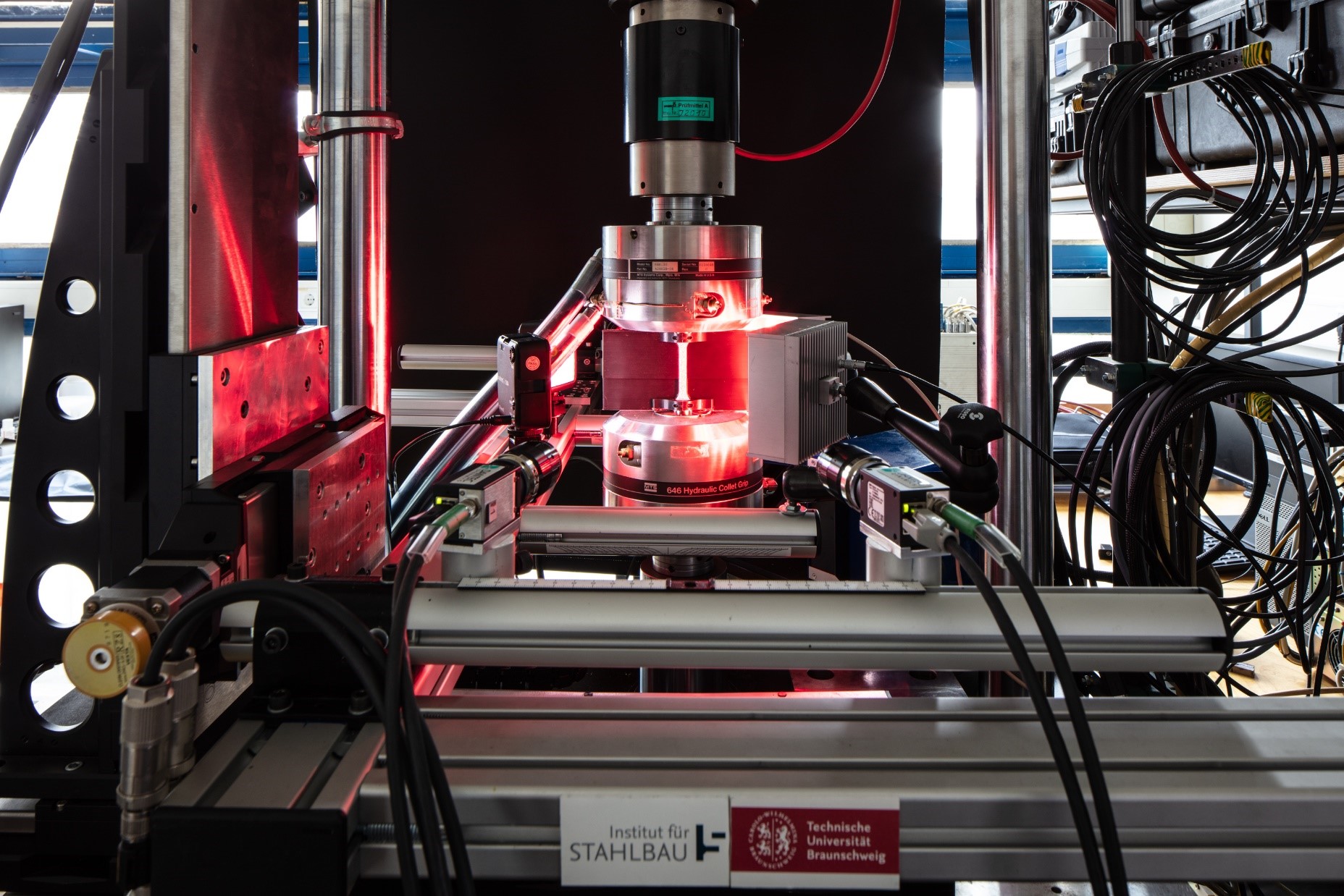

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components [08.09.2023] Jahns, Hendrik; Doctoral researcher; h.jahns@stahlbau.tu-braunschweig.de Unglaub, Julian; Principle Investigator j.unglaub@stahlbau.tu-braunschweig.de Thiele, Klaus; Principle Investigator k.thiele@stahlbau.tu-braunschweig.de Institute of Steel Structures Technische Universität Braunschweig Project – main goal In project A07 the design, manufacturing and mechanical properties of complex individualized WAAM steel nodes for use in construction is investigated. A new method is developed to design force flow optimized steel nodes as connectors between semi-finished parts and anchorage structures considering the manufacturing possibilities of the WAAM-process and the resulting material behavior. The manufacturing possibilities will be identified by case study demonstrators, which represent occurring features of the designed node. The produced parts are characterized regarding their mechanical properties. …

Research Summary Report of A08

Category: Research Summary Report

Structural Timber by Individual Layer Fabrication (ILF) [01.09.2023] Asshoff, Carsten; Doctoral researcher; carsten.asshoff@wki.fraunhofer.de Fraunhofer Institute for Wood Research Wilhelm-Klauditz-Institut WKI Main goal The main goal of the project ’A08 – Structural Timber by Individual Layer Fabrication (ILF)’ is to develop a process to additively manufacture large-scale, wood composite objects with a maximum content of wood material and strength values suited for applications in construction. In the course of the project multiple process variants and material combinations are explored. For this, the necessary machinery is developed in iterative steps and the mechanical properties of the resulting objects as well as the geometric capacity of the processes are investigated. Finally, multiple demonstrators are fabricated for showcase purposes. Summary Working …