Research Summary Report of A05

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

[03.02.2023]

Rothe, Tom; Doctoral researcher, t.rothe@tu-braunschweig.de,

Hühne, Christian; Project Leader, Christian.Huehne@tu-braunschweig.de,

TU Braunschweig, Institute for Mechanics and Adaptronics (IMA)

The individual integration of fibre reinforcement into large concrete components produced by Additive Manufacturing allows new design freedoms and reduces concrete consumption due to reduced concrete cover. The project A05 develops strategies to integrate freely formable reinforcement strands for the different AM processes. For doing so, a Dynamic Winding Machine is developed and constantly updated. This machine is used to consolidate and impregnate a primary fibre strand and wind a secondary yarn around it as a surface structuring. Thus, these reinforcement strands can be adapted for different purposes and enable more efficient production of highly customised, reinforced concrete elements.

Summary

Within the WG Hühne of A05, the individualized prefabrication of reinforcement strands by a developed Dynamic Winding Machine (DWM) is addressed, while WG Hack is focusing on strategies for the integration of the reinforcement strands into the different AM methods of the AMC.

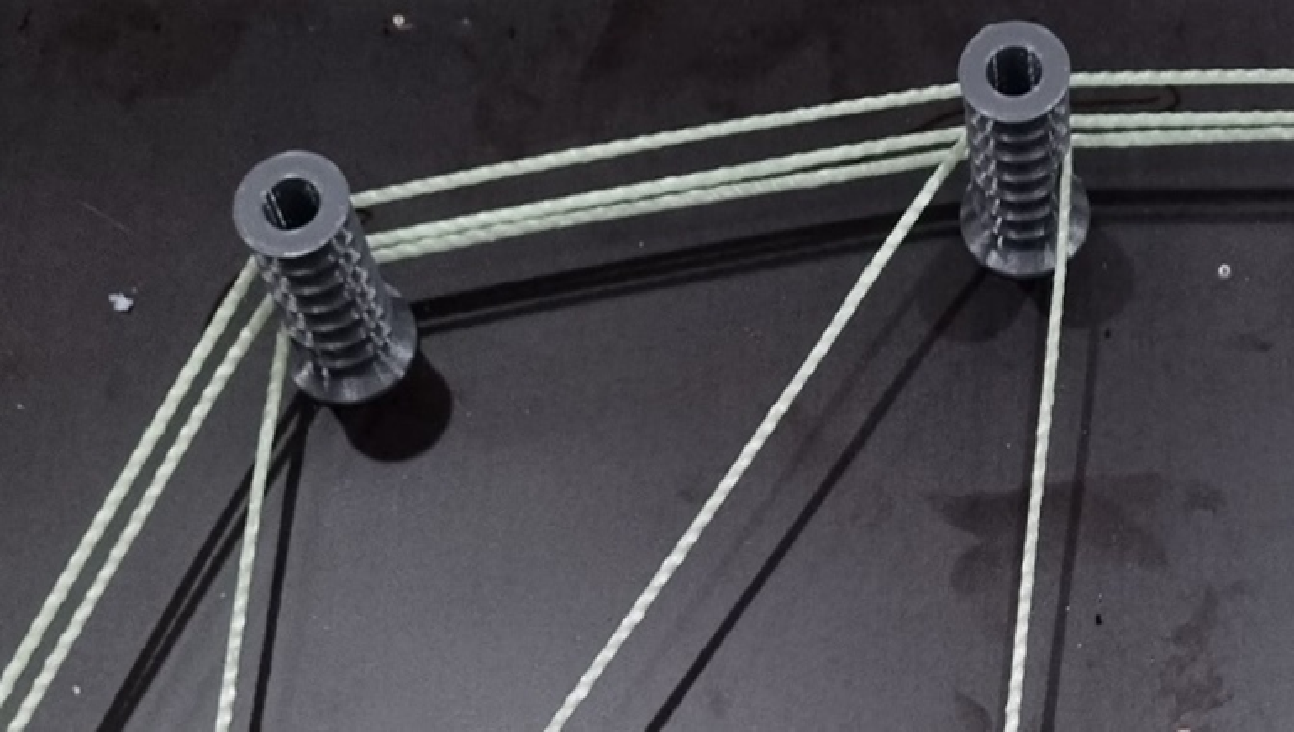

The on-going development of the DWM lead to major improvements in the adjustability of the producible fibre reinforcement strands. In particular, it was possible to achieve significantly more precise settings of the helix winding by means of adapted control electronics. This applies to the helix thread pitch on the one hand and the force with which the helix is wound around the primary fibre strand on the other. This makes it possible to achieve a slack or a tight winding of the secondary yarn. To gain knowledge on the mechanical properties of different reinforcement strands produced by the DWM tension and pull-out testing has been carried out in cooperation with the iBMB and MPA. The test setup for pull-out tests according to Rilem RC6 can be seen in Fig 1. With a sprayable, fine-grained concrete (max. aggregate size = 2 mm) that is also used by project A04 for the SC3DP process, bond strength varied between 15 and 22.5 MPa, depending on the surface structuring. Commercial rebars also tested were in the same range. Tension tests according to ASTM D7205 showed a tension modulus up to 41 GPa and a tensile strength up to 850 MPa, depending on the diameter and surface structuring.

Besides the intense investigation of the mechanical properties robotic winding approaches with a newly designed end effector has been carried out. By using this end effector it should be possible to wind thicker reinforcement strands with high quality. Some results of the first winding experiments can be seen in Fig 2.

Current state of research

The evaluation of the conducted pull-out tests is still ongoing. In a first series of tests fundamental information have been gained. Based on these a second series of tests with changed reinforcement properties has been carried out. The evaluation of the influences of different DWM settings to derive a deeper knowledge of the interlocking processes to concrete is a main focus. In combination with advanced investigations of the robotic winding process for different reinforcement integration strategies of A05 additional mechanical testing will be carried out. The goal is to evaluate the influence of the robotic winding on the mechanical properties of the reinforcement strands.