Research

Focus area A “Materials and Processes”

Focus area A “Materials and Processes” centres on the investigation of basic principles for the development from scratch of unique AMC processes for concrete, steel, and timber. As mentioned above, the innovation potential of the proposal is based primarily on the merging of material and process developments produced in interdisciplinary research teams.

Show More

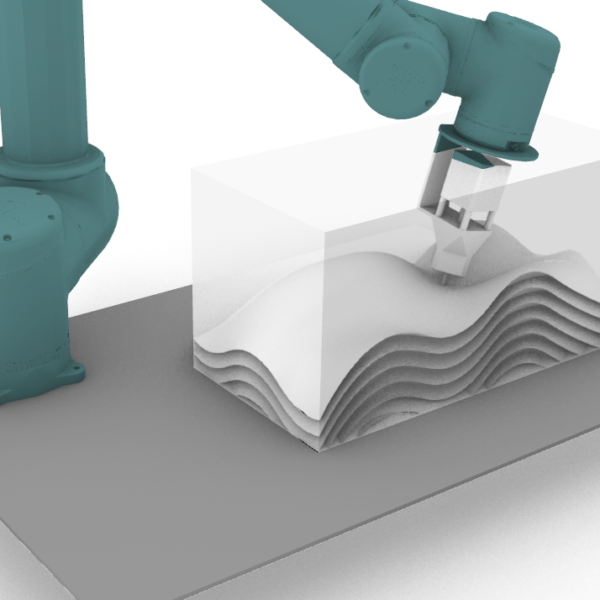

Based on the state of research and the results of preliminary research projects carried out by the applicants, two groups of additive manufacturing technologies are considered promising for implementation in construction: (1) particle-bed 3D printing techniques and (2) deposition 3D printing techniques.

Particle-bed 3D printing techniques include selective cement activation (SCA) (A01) and selective paste intrusion (SPI) (A02) for concrete, as well as selective laser melting (SLM) (A06) for steel and individual layer fabrication (A08) for timber. Among the deposition techniques, extrusion 3D printing (A03) and shotcrete 3D printing (SC3DP) (A04) for concrete, as well as wire and arc additive manufacturing (WAAM) (A07) for steel are considered.

Focus Area B “Computational Modelling and Control”

The experimentally driven investigations of focus area A ‘Materials and Processes‘ are enhanced by the corresponding projects of focus area B ‘Computational Modelling and Control’. All AM processes will be developed by taking into account assigned digital feedback obtained by computational modelling and process control.

Show More

The aim of focus area B is the development of novel models and efficient discretisation schemes for numerical simulation of material–process interactions relevant to additive manufacturing processes in construction.

From the modelling point of view, the focus is on the rheological behaviour of concrete during extrusion (B02, B03) and on the thermo-mechanical behaviour of steel during selective laser melting (B01). On the computational side, a suite of discretisation procedures will be developed, including DEM, FEM, and Lattice Boltzmann methods. Additionally, the coupling of multiple discretisation techniques will be required due to the complexity of the described phenomena.

During the first funding period, primarily A projects A03, A04 and A07, for which sufficient information about the material behaviour is available from preliminary research, will be supported with modelling and simulations (B01-B03). In the course of the second funding period, the area of computational modelling will be expanded to all A projects. Furthermore, a special focus will be on process control and path planning for the robot-assisted AM techniques. Therefore, project B04 is tied to the robotic manufacturing methods of projects A04 and A05. Project B 05 is related to project A03. Kathrin Dörfler, freshly appointed professor for Digital Fabrication at TU Munich, will focus on the integration of mobile robots in the extrusion-based AM process of A03 by investigating the principles of mobile robotics for AM and the potential opportunities that these processes can bring to on-site construction.

Focus area C “Design and Construction”

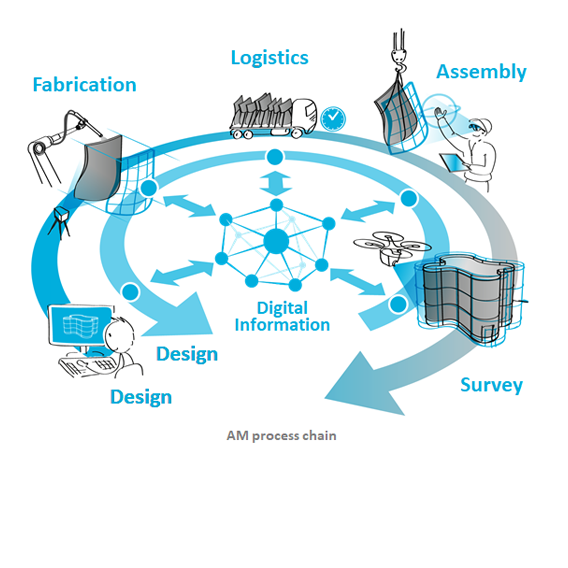

Focus area C “Design and Construction” addresses the most important subjects related to the implementation of additive manufacturing in the process chain of design and construction. The interaction between digital models and physical objects forms the methodical relationship within TRR 277 and connects the focus areas A and C.

Show More

This “digital/real relationship” will be addressed by physical demonstration objects with assigned digital twins (digital/real demonstrators).

This focus area provides feedback to the A projects by investigating novel design techniques and structural optimisation (C01, C02) as well as innovative assembling principles for additively manufactured structural elements (C05).

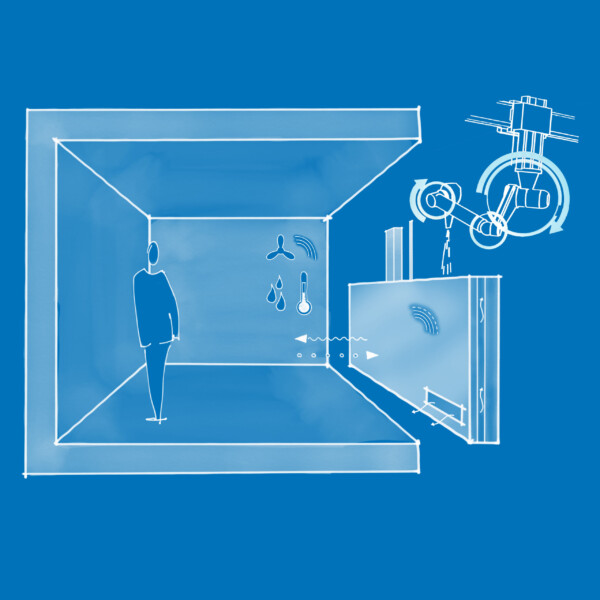

Project C 03 can be considered as a first attempt to integrate extended functions from the area of technical building equipment, building physics, and energy aspects. This research area will be expanded in the following funding periods.

Any information about building information modelling (BIM) will converge in project C04. The central research question of C04 is the investigation of the seamless digitalization in construction, and especially the clarification of the interface between planning and production. In project C04 the information from all the projects of focus area C meshes. In the second funding period, Christoph Herrmann (TUBS / IWF) will join the project to extend the BIM models with controlled material flow models in order to carry out ecological assessments.

The effects associated with the implementation of innovative AM processes in the construction industry will be addressed (C06). In this context, the feedback with respect to element configuration and dimensions of the additively manufactured large-scale structural elements, and the fact that constructions are always immovable, are of central importance. The questions of whether a higher degree of prefabrication due to AMC is a suitable goal or whether in-situ production will keep being of major importance in construction will be addressed in this project.

Finally, future job profiles for skilled workers as well as technical regulations in the area of AMC will be investigated in project C07. This is important for creating the prerequisites for this new technology to be accepted in the construction industry. AMC creates new job opportunities with significantly higher skill levels than traditional construction jobs. Moreover, for the application of additive manufacturing processes in construction practice, the development of adapted technical standards is of essential importance.

Vertex Morphing Applications, SiemensNX PlugIn, Carbody, AeroSpace Shape Opt. Topology Optimization of a Wing Box 3D-Printed Optimized Tensegrity Node, Made of Aluminum and Manufactured using Laser Po…

Project leaders

Dr. Sc. Pierluigi D’Acunto

is TT-assistant Professor at the Professorship of Structural Design –Technical University of Munich. In his doctoral research the focus is on vector- based 3D graphic statics and design of spatial structures based on the relation between form and forces.

Project(s)

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces

Prof Dr.-Ing. Roland Wüchner

He has been Head of the Institute of Statics and Dynamics at TU Braunschweig since September 2021.

Project(s)

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces

Contributors

M. Sc. Christiane Richter

Christiane Richter is a research associate and doctoral candidate at the Professorship of Structural Design at the TUM School of Engineering and Design. Under the guidance of Prof. Dr. Pierluigi D’Acunto, she is conducting research within the C02 project. With a solid foundation in structural engineering and expertise in concrete Additive Manufacturing, her primary focus lies in formulating a Holi…

Project(s)

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces

Networking with other projects Integration of Passive and Active Functions in Additively Manufactured Construction Elements This project aims to develop and test additively manufactured building compo…

Project leaders

Prof. Dipl.-Ing. Thomas Auer

is the head of the Chair of Building Technology and Climate Responsive Design at TUM. As such, the core focus in teaching and research is a holistic design approach for buildings in consideration of sustainability and energy-efficiency. He guides scientific personnel within research projects on the application of simulation-software as planning instrument for the numerical calculation of thermal, lighting and flow specific processes. These insights with practical relevance can be made in the fields of thermal comfort, energy consumption and daylight supply. In research, the chair is conducting several projects with various sources of funding from public or private sector, on state, federal and European level.

Project(s)

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

Contributors

M. Sc. David Briels

is a doctoral researcher and research associate at the Chair of Building Technology and Climate Responsive Design at TUM. Under the lead of Prof. Thomas Auer he conducts the research activities within C03. In particular he is developing a building simulation framework for a performance-based parametric design process, integrating passive and active functions in AM construction elements.

Project(s)

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

M. Sc. Ahmad Nouman

is a research associate at the Chair of Building Technology and Climate Responsive Design. The doctoral researcher focuses on decentralizing the active strategies to minimize energy consumption and improve thermal and visual comfort in built environments. He shares all responsibilities in the context of C03 essentially, modeling the simulations and designing experiments to develop additive manufac…

Project(s)

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

Networking with other projects Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods The project contributes to bridging the gap between dig…

Project leaders

Prof. Dr.-Ing. André Borrmann

acts as co-lead in project C04. He is responsible for leading and guiding WP2 and WP 3 and parts of WP 4. He is also responsible for coordinating the collaboration with other projects. He leads the doctoral researcher in the design and implementation of the virtual common research environment. He is responsible for the coordination of the projects in the TRR 277 and the coordination with the Leibniz Supercomputing Centre (LRZ).

Project(s)

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods

Prof. Dr.-Ing. Frank Petzold

acts as co-lead in this research project. He is responsible for leading and guiding WP1 and parts of WP 4. He is also responsible for coordinating the collaboration with other projects. He leads the doctoral researcher in the design and implementation of the research data management & publication platform. He is responsible for the coordination of the research projects in the TRR 277 and the coordination with the University Library of the Technical University of Munich.

Project(s)

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods

Contributors

M. Sc. Chao Li

His task is to develop a DDSS at a early design phase integrating AM. The expected system needs to combine both hard rules (boundary conditions) and experts’s experience, in order to advise the designer (architect) for feasible AM methods regarding to different building components.

Project(s)

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods

M. Sc. Martin Slepicka

is developing a data structure and corresponding methods (WP 2) that enable a closed chain between digital design (e.g. BIM) and digital manufacturing (mainly Additive Manufacturing). For backwards communication of “as-built” information during and after a manufacturing process, digital twin methods are incorporated into the developed FIM system (WP 3).

Project(s)

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods

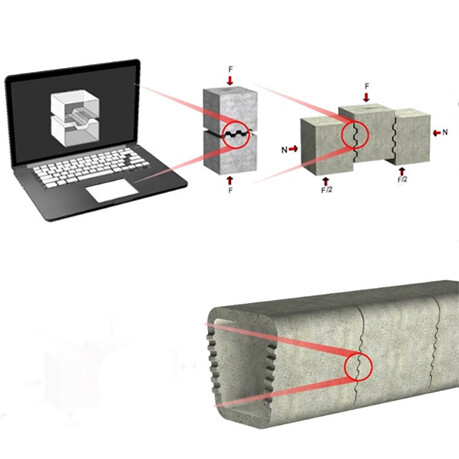

Demonstrator Experimental Testing Specimens for compression strength analysis of dry joints Roughing and finishing tool along with the simulation of the C4 CNC process Evaluation of the 3D geometrical…

Project leaders

Prof. Dr.-Ing. Martin Empelmann

instructs the research engineer at iBMB in the conceptual structure, execution and evaluation of the theoretical, experimental and numerical research work.

Project(s)

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Prof. Dr.-Ing. Harald Kloft

leads the scientific staff in the orientation and execution of the design process creation and supports them in an advisory capacity in the creation of test geometries and demonstrators. He is responsible for the content and organisational coordination of all work on the part of ITE. He instructs the research engineer at ITE in the conceptual structure, execution and evaluation of the theoretical and experimental research work. He is the spokesperson of the TRR 277.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Central Tasks of the AMC

Contributors

Dr.-Ing. Abtin Baghdadi

is a research associate at Institute of Structural Design (ITE) of TU Braunschweig. He is responsible for experimental, theoretical and numerical research work as well as for the coordination of the cooperations within the SFB.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Program Networking with other projects Integration of Additive Manufacturing in the Construction Process The introduction of additive manufacturing in construction is expected to lead to fundamental c…

Project leaders

Prof. Dr.-Ing. Markus Gerke

will instruct the other doc. researcher in the fields of surveying, scanning and machine learning. A particular task will be the coordination of participants involved with this and other projects.

Dipl.-Ing. M.A. AA Norman Hack

is supervising ITE`s requested doctoral researcher during all phases of the research. Additionally, he is actively involved in the conceptual phase, developing reinforcement concepts for the different AM methods.

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Integration of Additive Manufacturing in the Construction Process

Prof. Dr.-Ing. Patrick Schwerdtner

is superviser of project C06 and leads one of the Doc. researchers especially concerning the selection and assessment of parameters and the basic layout of the process analysis. His expertise is used to develop (new) process models and innovative delivery approaches in the later phase. He is also responsible for the overall coordination of project C06 and the projects belonging to different Work Programmes ( 1.1, 2.1 and 3.).

Contributors

Dr.-Ing. Mehdi Maboudi

is an associate researcher at the IGP and will help with supervision of one of the doctoral researchers. His expertise in computer vision, scanning technologies and implementing deep learning methods will be used in this project.

M. Sc. Karam Mawas

Doctoral researcher at IGP: The researcher Will Provide an inspection process chain utilizing new digital tools to perform the quality inspection of the as-built model of AMC products (mainly concrete) with its digital twin on the component level. Moreover, the next focus would be building scale monitoring of the construction site and establishing accurate coordinate systems to support the positio…

M. Sc. Gerrit Placzek

Doctoral researcher at IBB: The doc. researcher will perform a cross-sectional role and work closely with both the other doc. researchers in C06 and on all the other projects mentioned in order to investigate fundamental AM processes and their construction-operational parameters. He will extend the basic knowledge of AM processes through the analysis of AM produced components. Furthermore, he will…

Methods Networking with other projects Challenges of Additive Manufacturing – Technical Regulations and Qualification Requirements As a first step and according to the gap in theory, C07 considers a f…

Project leaders

Prof. Dr. phil. Daniel Pittich

leads the research fellows according to the WP in th eprocesses of exploration ,identification and evaluation of AM in the context of technology, parameters and operational processes. On this basis, he supports the analysis and transformation of the data for specific Qualification Concepts as well as the development of the framework of aspects of qualification concepts in AM. In co-operation with PL Winter, he is responsible for the co-ordinating adaptation to the cooperating projects of TRR 277 (WP 1).

Project(s)

Challenges of Additive Manufacturing – Technical Regulations and Qualification Requirements

Prof. Dr.-Ing. Stefan Winter

acts as supervisor for the research fellows and gives special input to the WPs related to Technical Regulations. He is responsible for the above allocated WPs and together with PL Pittich for cooperation with allocated projects of TRR 277 and the management of project C07.

Project(s)

Challenges of Additive Manufacturing – Technical Regulations and Qualification Requirements

Contributors

M. Sc. Birger Buschmann

is a mechanical engineer and doctoral researcher at TUM-HBB. For the project A08 he will work out the details of the fabrication process and is responsible for the topic of automatization. In C07 his responsibilities include the development of data acquisition concepts in order to identify relevant process parameters as well as the evaluation of generated data in order to form concepts for regulat…

Project(s)

Structural Timber by Individual Layer Fabrication (ILF)

Challenges of Additive Manufacturing – Technical Regulations and Qualification Requirements

M. Ed. Tobias Ludwig

is a doctoral researcher at the Professorship of Technical Education at TUM School of Social Sciences and Technology. The focus of his work in C07 is on the competence and qualification requirements of the involved experts in order to have trained professionals for a later implementation of AMC. For this, the different processes must be analyzed in their entirety from the perspective of handling a…

Project(s)

Challenges of Additive Manufacturing – Technical Regulations and Qualification Requirements

M. Sc. Daniel Talke

is a doctoral researcher and expert on additive manufacturing in construction. His previous work includes extrusion as well as selective binding processes of concrete. He will be responsible at TUM-HBB for all the collaborative work to be executed in conjunction with WKI in project A08, especially for WP 2.

Project(s)

Structural Timber by Individual Layer Fabrication (ILF)

Challenges of Additive Manufacturing – Technical Regulations and Qualification Requirements

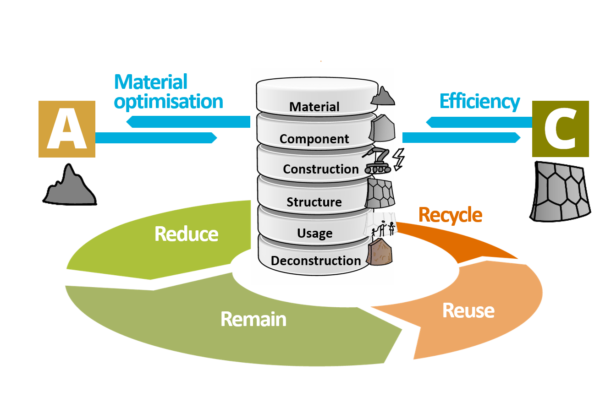

Networking with other projects Environmental Life Cycle Assessment – Determination of Ecological Sustainability Potentials by AMC Additive manufacturing in construction (AMC) is a viable option…

Project leaders

Prof. Dipl.-Ing. Charlotte Thiel

is Professor of „Construction Materials “ at Regensburg University of Applied Sciences. She is Head of Concrete Laboratory and Head of Construction Materials Laboratory. Furthermore she coordinates all scientific and organisational work regarding testing and material modelling.

Project(s)

Environmental Life Cycle Assessment – Determination of Ecological Sustainability Potentials by AMC

Contributors

M. Eng. Sophie Viktoria Albrecht

Is a doctoral researcher at the faculty of civil engineering at the OTH Regensburg. She is responsible for the environmental Life Cycle Assessment of additive manufacturing techniques in construction. Furthermore, the researcher will establish a database for the environmental footprint of additive manufactured materials as well as methods, components and structures using AMC.

Project(s)

Environmental Life Cycle Assessment – Determination of Ecological Sustainability Potentials by AMC

Learning, Sustainability, Design: Gender-equitable introduction of AMC to the public TRR 277 AMC researches innovative additive manufacturing methods, materials, and optimized designs and processes to…

Project leaders

Prof. Dr. sc. Kathrin ETH Dörfler

leads the scientific staff in the conception and execution of the research, and in questions of validation of the proposed methods. She is also responsible for the coordination of the cooperating research projects in the TRR 277. She is the Co-Spokesperson of the TRR 277. Dörfler supports Kloft as contact person for the DFG, in general public relation matters and also in representing the TRR 277 externally. Internally, Dörfler assists Kloft in the coordination between the research projects, as well as in the decisions on the financing of research tasks in the TRR 277.

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Principles of Mobile Robotics for Additive Manufacturing in Construction

Learning, Sustainability, Design: Gender-equitable introduction of AMC to the public

Central Tasks of the AMC

Prof. Dr. Anna Keune

is Professor at the School of Social Science and Technology ( Department of Educational Sciences) –Technical University of Munich. In her research she focuses on Education and learning Sciences.

Project(s)

Learning, Sustainability, Design: Gender-equitable introduction of AMC to the public

Prof. Dr.-Ing. Harald Kloft

leads the scientific staff in the orientation and execution of the design process creation and supports them in an advisory capacity in the creation of test geometries and demonstrators. He is responsible for the content and organisational coordination of all work on the part of ITE. He instructs the research engineer at ITE in the conceptual structure, execution and evaluation of the theoretical and experimental research work. He is the spokesperson of the TRR 277.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Central Tasks of the AMC

Contributors

M. A. Živa Simšič

is a doctoral researcher at Rudolf Mößbauer Tenure Track Assistant Professorship of Learning Sciences and Educational Design Technologies, TUM School of Social Sciences and Technology, and TUM Institute for Advanced Study (IAS). Živa’s background in arts education serves Project Ö’s constructionist and design-based research initiative to create the AMC Edu:Lab, a dynamic learning space designed fo…

Project(s)

Learning, Sustainability, Design: Gender-equitable introduction of AMC to the public

The service project Information Infrastructure serves and supports all information and data infrastructure aspects of the TRR 277 in close cooperation with the Leibniz-Supercomputing Centre (LRZ) and…

Project leaders

Dr. rer. nat. Christine Wolter

Head of Research Data Services

Project(s)

The service project Information Infrastructure serves and supports all information and data infrastructure aspects of the TRR 277 in close cooperation with the Leibniz-Supercomputing Centre (LRZ) and the University Library at the Technical University of Munich and the University Library Braunschweig.

Contributors

Dr. Silke Sturm

Silke Sturm works at the University Library of the Technical University of Munich. In her function as Data Steward she is responsible for the Data Management strategies and support. She works on defining discipline-specific standards, repositories and research data infrastructure. Moreover, she develops new coaching material for various topics concerning best practices in research data management.

Project(s)

The service project Information Infrastructure serves and supports all information and data infrastructure aspects of the TRR 277 in close cooperation with the Leibniz-Supercomputing Centre (LRZ) and the University Library at the Technical University of Munich and the University Library Braunschweig.

Central Tasks of the AMC Central Tasks (CT) is dealing with day-to-day-management of the TRR 277 AMC. The CT Office supports the spokesperson Harald Kloft and co-spokesperson Kathrin Dörfler in managi…

Project leaders

Prof. Dr. sc. Kathrin ETH Dörfler

leads the scientific staff in the conception and execution of the research, and in questions of validation of the proposed methods. She is also responsible for the coordination of the cooperating research projects in the TRR 277. She is the Co-Spokesperson of the TRR 277. Dörfler supports Kloft as contact person for the DFG, in general public relation matters and also in representing the TRR 277 externally. Internally, Dörfler assists Kloft in the coordination between the research projects, as well as in the decisions on the financing of research tasks in the TRR 277.

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Principles of Mobile Robotics for Additive Manufacturing in Construction

Learning, Sustainability, Design: Gender-equitable introduction of AMC to the public

Central Tasks of the AMC

Prof. Dr.-Ing. Harald Kloft

leads the scientific staff in the orientation and execution of the design process creation and supports them in an advisory capacity in the creation of test geometries and demonstrators. He is responsible for the content and organisational coordination of all work on the part of ITE. He instructs the research engineer at ITE in the conceptual structure, execution and evaluation of the theoretical and experimental research work. He is the spokesperson of the TRR 277.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Central Tasks of the AMC

Contributors

Ms. B.Sc. Cecilia S. Ahumada

Finance Manager of TRR 277

M.A. Meike Bährens

PR & Communication Coordinator. She is in charge of the public relations and communication of the SFB TRR 277 AMC and presents the AMC to a broad interested public. She is part of the AMC office.

M. Sc. Gido Dielemans

is a doctoral researcher at the TT Professorship for Digital Fabrication within TUM. With background in structural design and engineering, he will develop strategies for using mobile robotic systems performing extrusion-based AM on construction sites. Fundamentally, this work is interdisciplinary, and he therefore strives for a high degree of collaboration within, but not limited to, the TRR277.

Project(s)

Principles of Mobile Robotics for Additive Manufacturing in Construction

Central Tasks of the AMC

Dr.-Ing. Jeldrik Mainka

General Manager / administrative coordinator. He is organizing the day-to-day management of the SFB TRR 277 AMC, supports the Speaker and Co- speaker such as the AMC Board in the coordination of the TRR 277. He is reporting to the AMC Board and is head of the AMC Business Office (AMC-Geschäftsstelle).

Ms. Yonca Taube

She supports the AMC in all administrative tasks.

- 1

- 2