Research

Focus area A “Materials and Processes”

Focus area A “Materials and Processes” centres on the investigation of basic principles for the development from scratch of unique AMC processes for concrete, steel, and timber. As mentioned above, the innovation potential of the proposal is based primarily on the merging of material and process developments produced in interdisciplinary research teams.

Show More

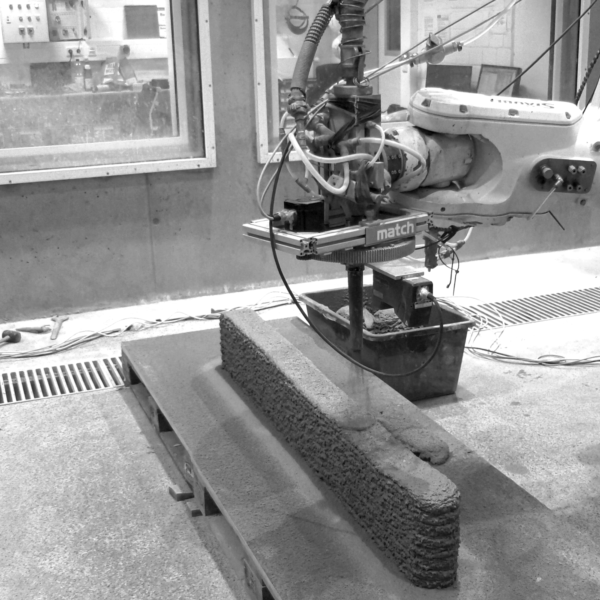

Based on the state of research and the results of preliminary research projects carried out by the applicants, two groups of additive manufacturing technologies are considered promising for implementation in construction: (1) particle-bed 3D printing techniques and (2) deposition 3D printing techniques.

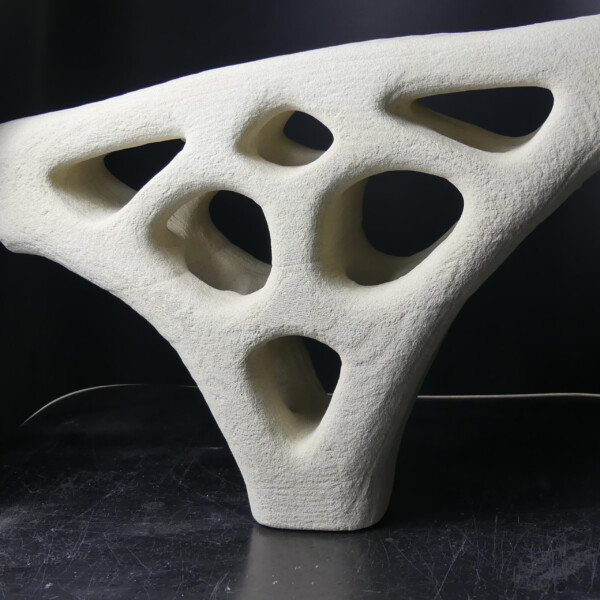

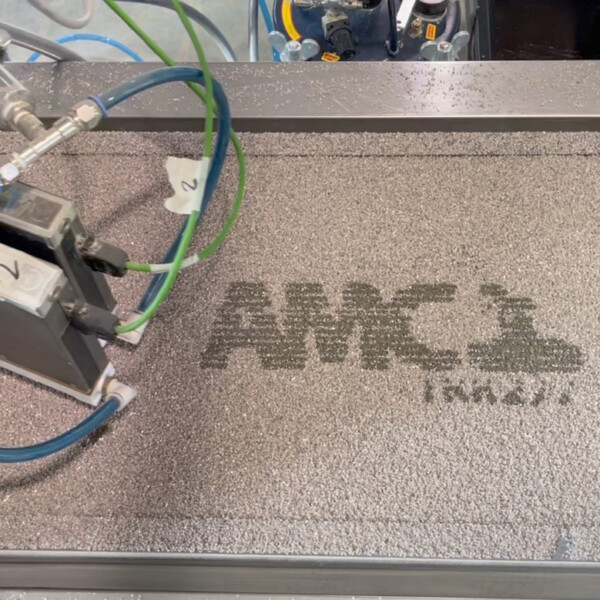

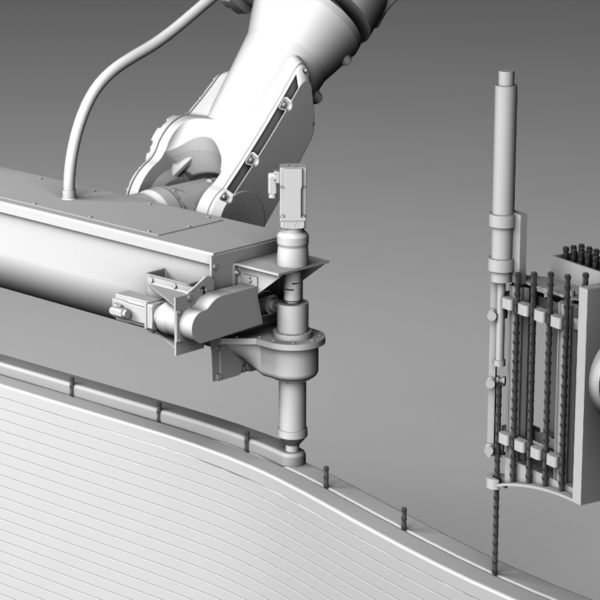

Particle-bed 3D printing techniques include selective cement activation (SCA) (A01) and selective paste intrusion (SPI) (A02) for concrete, as well as selective laser melting (SLM) (A06) for steel and individual layer fabrication (A08) for timber. Among the deposition techniques, extrusion 3D printing (A03) and shotcrete 3D printing (SC3DP) (A04) for concrete, as well as wire and arc additive manufacturing (WAAM) (A07) for steel are considered.

Focus Area B “Computational Modelling and Control”

The experimentally driven investigations of focus area A ‘Materials and Processes‘ are enhanced by the corresponding projects of focus area B ‘Computational Modelling and Control’. All AM processes will be developed by taking into account assigned digital feedback obtained by computational modelling and process control.

Show More

The aim of focus area B is the development of novel models and efficient discretisation schemes for numerical simulation of material–process interactions relevant to additive manufacturing processes in construction.

From the modelling point of view, the focus is on the rheological behaviour of concrete during extrusion (B02, B03) and on the thermo-mechanical behaviour of steel during selective laser melting (B01). On the computational side, a suite of discretisation procedures will be developed, including DEM, FEM, and Lattice Boltzmann methods. Additionally, the coupling of multiple discretisation techniques will be required due to the complexity of the described phenomena.

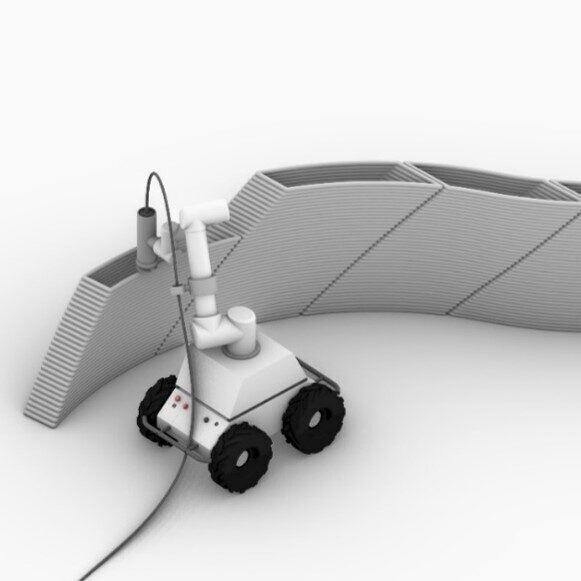

During the first funding period, primarily A projects A03, A04 and A07, for which sufficient information about the material behaviour is available from preliminary research, will be supported with modelling and simulations (B01-B03). In the course of the second funding period, the area of computational modelling will be expanded to all A projects. Furthermore, a special focus will be on process control and path planning for the robot-assisted AM techniques. Therefore, project B04 is tied to the robotic manufacturing methods of projects A04 and A05. Project B 05 is related to project A03. Kathrin Dörfler, freshly appointed professor for Digital Fabrication at TU Munich, will focus on the integration of mobile robots in the extrusion-based AM process of A03 by investigating the principles of mobile robotics for AM and the potential opportunities that these processes can bring to on-site construction.

Focus area C “Design and Construction”

Focus area C “Design and Construction” addresses the most important subjects related to the implementation of additive manufacturing in the process chain of design and construction. The interaction between digital models and physical objects forms the methodical relationship within TRR 277 and connects the focus areas A and C.

Show More

This “digital/real relationship” will be addressed by physical demonstration objects with assigned digital twins (digital/real demonstrators).

This focus area provides feedback to the A projects by investigating novel design techniques and structural optimisation (C01, C02) as well as innovative assembling principles for additively manufactured structural elements (C05).

Project C 03 can be considered as a first attempt to integrate extended functions from the area of technical building equipment, building physics, and energy aspects. This research area will be expanded in the following funding periods.

Any information about building information modelling (BIM) will converge in project C04. The central research question of C04 is the investigation of the seamless digitalization in construction, and especially the clarification of the interface between planning and production. In project C04 the information from all the projects of focus area C meshes. In the second funding period, Christoph Herrmann (TUBS / IWF) will join the project to extend the BIM models with controlled material flow models in order to carry out ecological assessments.

The effects associated with the implementation of innovative AM processes in the construction industry will be addressed (C06). In this context, the feedback with respect to element configuration and dimensions of the additively manufactured large-scale structural elements, and the fact that constructions are always immovable, are of central importance. The questions of whether a higher degree of prefabrication due to AMC is a suitable goal or whether in-situ production will keep being of major importance in construction will be addressed in this project.

Finally, future job profiles for skilled workers as well as technical regulations in the area of AMC will be investigated in project C07. This is important for creating the prerequisites for this new technology to be accepted in the construction industry. AMC creates new job opportunities with significantly higher skill levels than traditional construction jobs. Moreover, for the application of additive manufacturing processes in construction practice, the development of adapted technical standards is of essential importance.

Approach Visuals Figure 2: 3D printing of prismatic specimens for bending tensile and compressive strength / Credit: Dreßler, iBMB TU Braunschweig Figure 3: De-powdering of a printed column / Credit:…

Project leaders

Kwade, Arno Prof. Dr.-Ing.

Head of the institute for particle technology. Head of iPAT and supports the academic staff regarding the conditioning of particle products.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Lowke, Dirk Prof. Dr.-Ing.

Prof. Dr.-Ing. Dirk Lowke is Chair of Materials and Methods in Digital Construction. He will advise the scientific staff in carrying out their work in line with the formulated project aims. He is responsible for the coordination and quality control of all work conducted by the Chair of Materials and Methods in Digital Construction at the Department of Materials Engineering at TU Munich.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Contributors

Dorresteijn, Evelien M. Sc.

is a researcher at Institute of Building Materials, Concrete Construction and Fire Safety and works for the project A01.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Herding, Friedrich M. Sc.

M. Sc. Friedrich Herding is a research associate in the working group of Prof. Dr.-Ing. Dirk Lowke. He is researching the material-process interaction in the SCA process.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Meier, Niklas M. Sc.

is a research associate in the work group of Prof. Dr.-Ing. Arno Kwade. He is responsible for the development of tailored particles for the SCA process.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Zetzener, Harald Dr.-Ing.

deputy director of the institute for particle technology, head of Division Powder and Slurry Processes, supports Prof. Kwade in leading the project.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Figure 1: Production cycle of SPI with WAAM reinforcement: I) application of the WAAM reinforcement, II) spreading of the next aggregate layer, III) intrusion of the cement paste in the target layer,…

Project leaders

Gehlen, Christoph Prof. Dr.-Ing.

Dean of TUM School of Engineering and Design, Head of cbm and leads project A02 and A03. He instructs and advises the academic staff regarding additive manufacturing and concrete technological questions. He is responsible for the coordination and quality control of all work of cbm. Untill Oct. 2021 he was the co-spokesperson of the TRR 277. He then became Dean of TUM School of Engineering and Design and handed over the tasks of Co-Speaker to Kathrin Dörfler.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Kwade, Arno Prof. Dr.-Ing.

Head of the institute for particle technology. Head of iPAT and supports the academic staff regarding the conditioning of particle products.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Zäh, Michael F. Prof. Dr.-Ing.

guides the scientific staff in the execution of the LPBF experiments.He provides guidance in methods for analysing the main mechanisms of action and the correlation of the results for the whole process chain. Head of iwb and supports the academic staff regarding additive manufacturing, alignment and execution of numerical heat transport simulations, questions during validation and process development.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience.

Contributors

Freidhofer, Markus-Sebastian M. Sc.

Markus Freidhofer is a research associate in the workgroup of Prof. Dr.-Ing. Michael F. Zäh. His research focuses on the combined process of stud welding and wire arc additive manufacturing (WAAM) for the production of structural reinforcements. This includes the simulation of the combined process, as well as process control and process monitoring for quality-assured manufacturing

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Hamilton, Leigh Duncan M. Sc.

is a research associate in the work group of Prof. Dr.-Ing. Arno Kwade. He is responsible for the development of tailored particles for the combined process of SPI and WAAM.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Kränkel, Thomas Dr.-Ing.

Head of workgroup concrete technology and assists Prof. Gehlen in leading project A02. He instructs and supports the academic staff regarding additive manufacturing and concrete technological questions.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Riegger, Felix M. Sc.

is a research associate in the workgroup of Prof. Dr.-Ing. Michael F. Zäh. As an expert in WAAM, he is responsible for the simulation and temperature modelling of the process.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Straßer, Alexander M. Sc.

is a research associate at the Workinggroup of Prof. Dr.-Ing. Christoph Gehlen. Responsible for research on selective paste intrusion and development of cement pastes.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Zetzener, Harald Dr.-Ing.

deputy director of the institute for particle technology, head of Division Powder and Slurry Processes, supports Prof. Kwade in leading the project.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Networking with other projects Poster TRR277_A03_230601_TP_Poster_FP1 TRR277_A03_230601_TP_Poster_FP2 Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Re…

Project leaders

Bos, Freek PhD M.Sc.

Team Leader for Extrusion-Based Additive Manufacturing of Concrete at the TUM School of Engineering and Design

Project(s)

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Fottner, Johannes Prof. Dr.-Ing.

Project leader in A03 and B02. He instructs and supports the academic staff regarding bulk conveying and machine design questions.

Project(s)

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Gehlen, Christoph Prof. Dr.-Ing.

Dean of TUM School of Engineering and Design, Head of cbm and leads project A02 and A03. He instructs and advises the academic staff regarding additive manufacturing and concrete technological questions. He is responsible for the coordination and quality control of all work of cbm. Untill Oct. 2021 he was the co-spokesperson of the TRR 277. He then became Dean of TUM School of Engineering and Design and handed over the tasks of Co-Speaker to Kathrin Dörfler.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Contributors

Cheng, Shengbo M. Sc.

is a research associate at TUM School of Engineering and Design. He works on structural analysis of functional graded concrete produced by near-nozzle mixing system in A03 and is responsible for evaluating the properties of graded concrete by means of experiments and modelling.

Project(s)

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Dahlenburg, Maximilian M. Sc.

is an expert in mechanical engineering, specialized in development, CAD-Design and construction of complex machines at the Chair of Materials Handling, Material Flow, Logistics within TUM. He is responsible for design, construction, automation, simulation and optimization of the near-nozzle continuous mixing system developed in A03. Furthermore he is responsible for the material supply and the mat…

Project(s)

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Grimm, Benedikt M. Eng.

is a doctoral researcher at the Centre for Building Material within TUM. He is responsible for the further development of the material established in the first project phase of A03. He further analysis all data, prepares reports, presentations and publications.

Project(s)

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Hechtl, Maximilian M. Sc.

is a research associate at the Working group of Prof. Dr.-Ing. Christoph Gehlen. Expert in material development of Extrusion Concrete for additive manufacturing.

Project(s)

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Kränkel, Thomas Dr.-Ing.

Head of workgroup concrete technology and assists Prof. Gehlen in leading project A02. He instructs and supports the academic staff regarding additive manufacturing and concrete technological questions.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Unterreiner, Michael M. Sc.

has a background in industrial engineering and biomimetics. Currently he is a doctoral student at the Chair of Materials Handling, Material Flow, Logistics within TUM and is responsible for the design, automation, and advancement of the near-nozzle continuous mixing system that was developed during the first project phase of A03.

Project(s)

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Networking with other projects Poster TRR277_A04_Poster_1-DFG-Begutachtung TRR277_A04_Poster_2-DFG-Begutachtung Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP)…

Project leaders

Dröder, Klaus Prof. Dr.-Ing.

advises the scientific staff in continuous consideration of the defined research objectives and investigates opportunities to generate novel research projects and publications. He is responsible for the content and organisational coordination of all work on the part of IWF.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Kloft, Harald Prof. Dr.-Ing.

leads the scientific staff in the orientation and execution of the design process creation and supports them in an advisory capacity in the creation of test geometries and demonstrators. He is responsible for the content and organisational coordination of all work on the part of ITE. He instructs the research engineer at ITE in the conceptual structure, execution and evaluation of the theoretical and experimental research work. He is the spokesperson of the TRR 277.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Central Tasks of the AMC

Lowke, Dirk Prof. Dr.-Ing.

Prof. Dr.-Ing. Dirk Lowke is Chair of Materials and Methods in Digital Construction. He will advise the scientific staff in carrying out their work in line with the formulated project aims. He is responsible for the coordination and quality control of all work conducted by the Chair of Materials and Methods in Digital Construction at the Department of Materials Engineering at TU Munich.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Contributors

Baghdadi, Abtin Dr.-Ing.

is a research associate at Institute of Structural Design (ITE) of TU Braunschweig. He is responsible for experimental, theoretical and numerical research work as well as for the coordination of the cooperations within the SFB.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Böhler, David M. Sc.

is a research assistant at the Technical University of Munich in the group of Prof. Dr. Lowke. Together with Jennifer Rudolph, he will lead and organise the material development and testing programme as well as the data analysis and material modelling within the Lowke group. David Böhler will focus on investigating the durability of 3D printed concrete.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

David, Martin M. Sc.

is a doctoral researcher at the Institute for Machine Tools and Production Technology (IWF) at TU Braunschweig. He is working on the development of different end effectors for an automated concrete reinforcement as well as the surface processing of printed SC3DP elements. Additionally he is developing different nozzle geometries for the SC3DP process. Moreover, he will frequently publish the resul…

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Dörrie, Robin M. Sc.

is a doctoral researcher for the duration of the research project. He is leading the A04 project and organising the development of new concepts and strategies for the integration of reinforcement in SC3DP elements. Furthermore he is investigating the SC3DP process, its limitations and the spatial effect for the application in architecture and design within the work group of Prof. Dr.-Ing. Harald K…

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Freund, Niklas M. Sc.

is a doctoral researcher for the duration of the research project. He will lead and organise the material development and testing program as well as the data evaluation and material modelling work within WG Lowke. Moreover, he will frequently publish the results achieved within the community.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Megnet, Manuel M. Sc.

is a doctoral researcher at the Institute for Machine Tools and Production Technology (IWF) at TU Braunschweig. He is working on the development of different end effectors for an automated concrete reinforcement. Additionally he is developing different nozzle geometries for the SC3DP process. Moreover, he will frequently publish the results achieved within the community.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Opolka, Anna Marie M. Sc.

is a doctoral researcher at the Institute for Machine Tools and Production Technology (IWF) at TU Braunschweig. She is specialized in robotic manufacturing processes, especially for additive manufacturing and supports the development for the processing of printed SC3DP elements within project A04.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Rudolph, Jennifer

is a research assistant at the Technical University of Braunschweig in the group of Prof. Dr. Lowke. Together with David Böhler, she will lead and organise the material development and testing programme as well as the data analysis and material modelling within the Lowke group. Jennifer Rudolph will focus on investigating the mix designs as well as the environmental and rheological optimisation of…

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

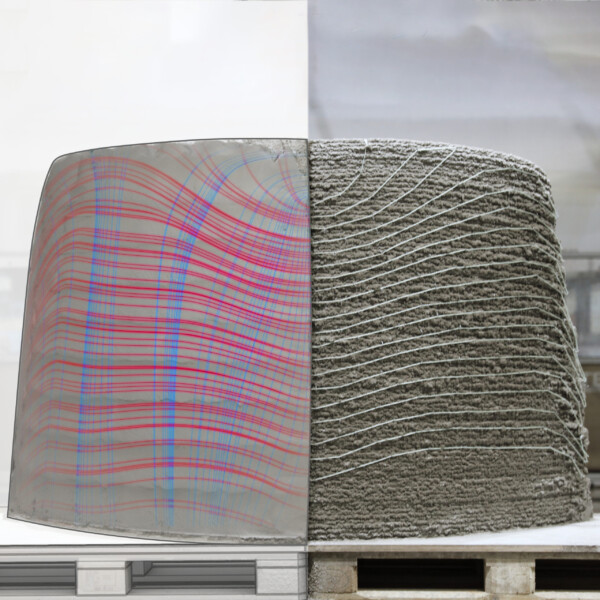

Half-covered real-scale case study for the combination of Core Winding Reinforcement and Shotcrete 3D Printing. The reinforcement layout was derived from principle stress analysis (overlay on the left…

Project leaders

Hack, Norman Dipl.-Ing. M.A. AA

is supervising ITE`s requested doctoral researcher during all phases of the research. Additionally, he is actively involved in the conceptual phase, developing reinforcement concepts for the different AM methods.

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Integration of Additive Manufacturing in the Construction Process

Hühne, Christian Prof. Dr.-Ing.

leads the iAF scientific staff in the development and construction of the winding head, the manufacturing process of the reinforcement from FRP with different curing resins, and in questions of the damage of the FRP by the shotcreting process.

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Contributors

Amiri, Fatemeh M. Sc.

Her focus centers on the exploration of innovative fiber reinforcement strategies, reflecting her role as a dedicated doctoral researcher.

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Gantner, Stefan M. Sc.

investigates fibre reinforcement strategies as doctoral researcher. In collaboration with project partners he develops techniques for processing fibres to obtain suitable reinforcement structures for different AM methods. Beyond conception his work scope ranges from deriving representative part designs to physical testing including prototyping of toolings.

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Mehdizadeh, Samim Dr.-Ing.

Dr.-Ing. Samim Mehdizadeh co-leads research activities and supervises doctoral researchers in the areas of lightweight concrete, on-site robotic fabrication, and multi-robotic fabrication. Within the Collaborative Research Center TRR 277 “Additive Manufacturing in Construction” (AMC), he co-leads the research projects A-05 and A-09 together with Prof. Norman Hack at the Institute for Structural De…

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Thiele, Philip M. Sc.

investigates the usability and properties of prefabricated fiber reinforcements, which are produced in a robotic winding process, for various AM processes. This includes the further development and sensing of an automated production process of fiber reinforcement for the requirements of the project. In addition, his work ranges from the integration of it into a self-controlling robotic winding pro…

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Shape-optimized tensegrity node manufactured by PBF-LB/M (vibratory ground and polished) Shape-optimized tensegrity node manufactured by PBF-LB/M (as-built with support structure) Typical microstructu…

Project leaders

Radlbeck, Christina Dr.-Ing.

leads scientific teams for AM, fatigue and fracture and aluminium at MB and is responsible for the MB Laboratory. She supervises experiments and provides assistance in analysis and interpre- tation of results

Project(s)

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience.

Zäh, Michael F. Prof. Dr.-Ing.

guides the scientific staff in the execution of the LPBF experiments.He provides guidance in methods for analysing the main mechanisms of action and the correlation of the results for the whole process chain. Head of iwb and supports the academic staff regarding additive manufacturing, alignment and execution of numerical heat transport simulations, questions during validation and process development.

Project(s)

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience.

Contributors

Blankenhagen, Jakob M. Sc.

is a doctoral researcher: Conducts scientific studies for the duration of the research project. Performs mechanical testing, fatigue testing, fracture mechanics testing, metallurgical analysis, and investigates the influence of geometry on structural performance. Analyzes all data and prepares reports, presentations, and publications.

Project(s)

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience.

Siebert, Dorina M. Sc.

Doctoral researcher: carrying out scientific studies. She will play a decisive role in planning and conducting fatigue and fracture testing. The evaluation and interpretation of test results is also one of her tasks. Finally she undertakes statistical considerations, which are intended to serve as a basis for the development of design guidelines.”

Project(s)

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience.

Suchowerchov, Julia M. Sc

is a research associate in the working group of Prof. Dr.-Ing. Michael F. Zäh. As an expert in powder bed fusion of metals using a laser beam (PBF-LB/M), she is responsible for the manufacturing process. Her research focuses on process parameter and process monitoring studies to improve material characterization. In addition, she conducts scientific investigations on the manufacturability of compl…

Project(s)

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience.

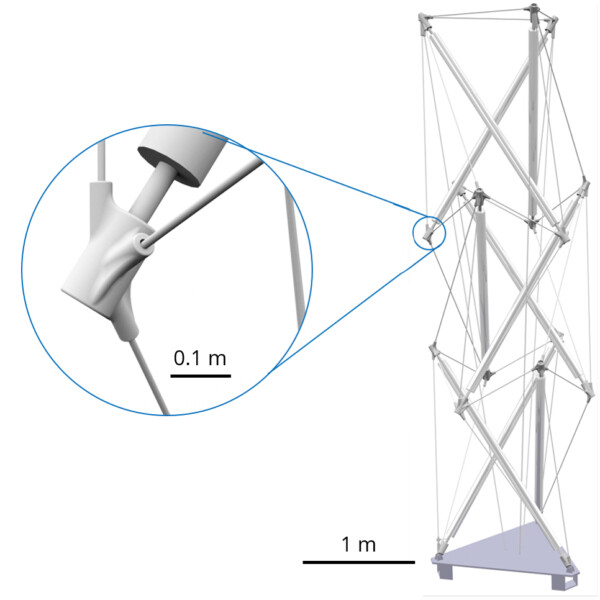

Node with minimum wall thickness and restricted overhang as constraints for topology optimisation using self-organising systems Anchorage structure produced by WAAM Thin-walled structure with one-side…

Project leaders

Hensel, Jonas Uni.-Prof. Dr.-Ing.

is Professor for Welding Engineering at Chemnitz University of Technology and takes responsibility for the management of this project in terms of content and organisation as well as the cooperation with project partners within the TRR 277. Furthermore, he supervises the research assistant of WG Hensel for welding experiments, metallographic characterisation, numerical analysis and residual stress determination.

Project(s)

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Kloft, Harald Prof. Dr.-Ing.

leads the scientific staff in the orientation and execution of the design process creation and supports them in an advisory capacity in the creation of test geometries and demonstrators. He is responsible for the content and organisational coordination of all work on the part of ITE. He instructs the research engineer at ITE in the conceptual structure, execution and evaluation of the theoretical and experimental research work. He is the spokesperson of the TRR 277.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Central Tasks of the AMC

Unglaub, Julian Dr.-Ing.

is head of division Material behavior at IS and takes responsibility for management of this project in terms of content and organization. He supervises the research assistants of WG Thiele for novel material and component testing methods based on MultiCam Digital Image Correlation (DIC) and the development of complex material models to describe WAAM-component behavior.

Project(s)

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Contributors

Altobelli, Martin Gabriel M. Sc.

studied mechanical engineering and recently completed my Master’s degree in Advanced Manufacturing at the Chair of Welding Technology at Chemnitz University of Technology. His thesis focused on a topic from the TRR 277 project, specifically the optimization of component accuracy in the DED-Arc process. He is now working as a researcher and PhD student, focusing on the learning-by-printing approach…

Project(s)

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Höfer, Kevin Dr.

Kevin Hoefer works as a post-doc at the Chair of Welding Technology and is responsible for the department “Materials and Design”. In the project, he supports Prof. Jonas Hensel in the administration and management of A07, in particular in the areas of welding experiments, metallographic characterisation and residual stress determination.

Project(s)

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Jahns, Hendrik M. Sc.

doctoral researcher at IS. He is responsible for the planning and execution of all scientific work, both numerical and experimental, in the framework of WAAM. This includes material and component testing, material modeling, analysis all data, prepares reports, presentations and publications.

Project(s)

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Jurke, Florian M. Sc.

is a research associate at the Chair of Welding Engineering at Chemnitz University of Technology. His focus is process analysis of arc-processes. He is particularly concerned with sensor integration and anomaly detection in arc-welding processes and additive manufacturing with wire and arc (DED-Arc).

Project(s)

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Ledderose, Lukas M. Sc.

is a postdoctoral researcher at the ITE. He is responsible for design strategies and possible applications. This includes the development of new structures, semi-finished parts and the concept for on-site WAAM as well as life cycle analysis and the creation of Digital Twins. He also prepares reports, presentations and publications.

Project(s)

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Müggenburg, Marc M. Sc.

doctoral researcher at IS. He is responsible for the planning and execution of all scientific work, both numerical and experimental, in the framework of WAAM. This includes material and component testing, material modeling, analysis of all data, preparation of reports, presentations and publications.

Project(s)

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Networking with other projects Poster TRR277_A08_Poster_1-DFG-Begutachtung Structural Timber by Individual Layer Fabrication (ILF) In project A08 a novel fabrication process named ‘individual layer fa…

Project leaders

Bunzel, Frauke Dr. rer. nat.

has been working in the field of wood adhesives for many years. She gives guidance and support to the academic staff at WKI regarding the entire adhesive systems including adhesives, particles and pressing parameters.

Henke, Klaudius Dr.-Ing.

has been working on additive manufacturing in construction for many years. This work also includes additive manufacturing with wood. He leads the project A08 and provides general guidance and support for the academic staff at HBB. In addition, he is responsible for the coordination of the proposed project within the TRR 277. He was a member of the AMC Board for the first funding period 2020-2023.

Contributors

Aßhoff, Carsten M. Sc.

is research associate at Fraunhofer Institute for Wood Research – Wilhelm-Klauditz-Institut WKI. In his doctoral research the focus is on the material development for additive manufacturing with wood.

Buschmann, Birger M. Sc.

is a mechanical engineer and doctoral researcher at TUM-HBB. For the project A08 he will work out the details of the fabrication process and is responsible for the topic of automatization. In C07 his responsibilities include the development of data acquisition concepts in order to identify relevant process parameters as well as the evaluation of generated data in order to form concepts for regulat…

Project(s)

Structural Timber by Individual Layer Fabrication (ILF)

Challenges of Additive Manufacturing – Technical Regulations and Qualification Requirements

Talke, Daniel M. Sc.

is a doctoral researcher and expert on additive manufacturing in construction. His previous work includes extrusion as well as selective binding processes of concrete. He will be responsible at TUM-HBB for all the collaborative work to be executed in conjunction with WKI in project A08, especially for WP 2.

Project(s)

Structural Timber by Individual Layer Fabrication (ILF)

Challenges of Additive Manufacturing – Technical Regulations and Qualification Requirements

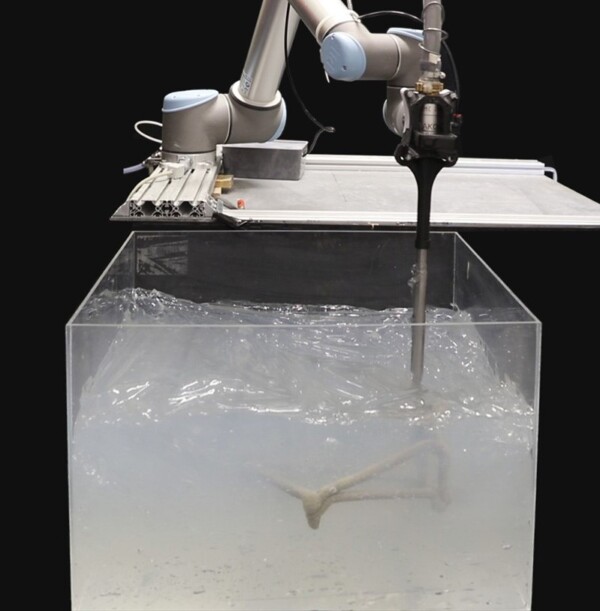

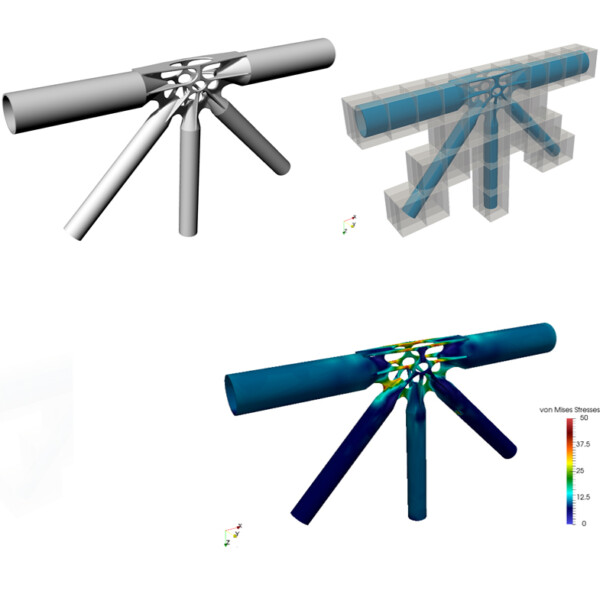

Networking with other projects Poster TRR277_A09_230503_Poster FP2_Begutachtung_Vorlage-PRINTED Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures B…

Project leaders

Hack, Norman Dipl.-Ing. M.A. AA

is supervising ITE`s requested doctoral researcher during all phases of the research. Additionally, he is actively involved in the conceptual phase, developing reinforcement concepts for the different AM methods.

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Integration of Additive Manufacturing in the Construction Process

Mai, Inka Dr.-Ing.

is Junior-Professor at the Institute of Civil Engineering, Department of Robotic Manufacturing of the Built Environment at Technische Universität Berlin.

Project(s)

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Contributors

Döring, Leon M. Sc.

has a background in architecture. Currently, he is a research associate at the Institute of Structural Design (ITE) at TU Braunschweig. His work on Injection 3D Concrete Printing (I3DCP) focuses on investigating strategies for design and fabrication as well as architectural applications. In collaboration with material researchers from TU Berlin, he conducts experiments on material and fabrication…

Project(s)

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Jacobi, Ando M. Sc.

Is a doctoral researcher at the Department of Robotic Manufacturing of the Built Environment at TU Berlin. His work in Project A09 focuses on investigating material and process parameters with regards to Injection Printing. This includes the fabrication of specimen using Injection Printing as well as studies on material properties. Project(s) Project A 09 Injection 3D Concrete Printing (I3DCP) – M…

Project(s)

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Mehdizadeh, Samim Dr.-Ing.

Dr.-Ing. Samim Mehdizadeh co-leads research activities and supervises doctoral researchers in the areas of lightweight concrete, on-site robotic fabrication, and multi-robotic fabrication. Within the Collaborative Research Center TRR 277 “Additive Manufacturing in Construction” (AMC), he co-leads the research projects A-05 and A-09 together with Prof. Norman Hack at the Institute for Structural De…

Project(s)

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Xiao, Yinan M.Sc.

Is a doctoral researcher at the Institute of Structural Design (ITE) at TU Braunschweig.

Project(s)

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Networking with other projects Poster TRR277_A10_Poster_1-DFG-Begutachtung Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials In rec…

Project leaders

Dörfler, Kathrin Prof. Dr. sc. ETH

leads the scientific staff in the conception and execution of the research, and in questions of validation of the proposed methods. She is also responsible for the coordination of the cooperating research projects in the TRR 277. She is the Co-Spokesperson of the TRR 277. Dörfler supports Kloft as contact person for the DFG, in general public relation matters and also in representing the TRR 277 externally. Internally, Dörfler assists Kloft in the coordination between the research projects, as well as in the decisions on the financing of research tasks in the TRR 277.

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Principles of Mobile Robotics for Additive Manufacturing in Construction

Learning, Sustainability, Design: Gender-equitable introduction of AMC to the public

Central Tasks of the AMC

Kloft, Harald Prof. Dr.-Ing.

leads the scientific staff in the orientation and execution of the design process creation and supports them in an advisory capacity in the creation of test geometries and demonstrators. He is responsible for the content and organisational coordination of all work on the part of ITE. He instructs the research engineer at ITE in the conceptual structure, execution and evaluation of the theoretical and experimental research work. He is the spokesperson of the TRR 277.

Project(s)

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Central Tasks of the AMC

Machner, Alisa Prof. Dr. (PhD)

is Professor at School of Engineering and Design, Department of Materials Engineering – Technical University of Munich. In her doctoral research the focus is on dolomite calcined clay composite cement.

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Contributors

Eichler, Hannes M. Sc.

is a structural engineer and doctoral researcher at the TUB Institute for Structural Design (ITE). He is responsible for Project A10 where he is researching on Sprayed Earth Additive Manufacturing (SEAM). This includes general investigations on earthen constructions as well as development of the SEAM process and the optimization of material-process interactions. Within the project, he will carry o…

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Gosslar, Joschua M.Sc.

Project(s) Project A 10 Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Krakovska, Ema M. Sc.

is a researcher at the TT Professorship for Digital Fabrication within TUM. She received her architecture master’s degree at TUM in 2022, focusing on computational methods in architecture. Project(s) Project A 10 Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Tsiotou, Sofia M. Sc.

is a doctoral researcher at the TUM Professorship of Mineral Construction Materials with a focus on clays and clay minerals for the purposes of the A10 project.

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Zavaleta, Diana M. Sc.

is a civil engineer and doctoral researcher at the TU Braunschweig Institute for Structural Design (ITE). She is responsible for Project A10, where she is conducting research on Sprayed Earth Additive Manufacturing (SEAM). Her work involves exploring earthen construction techniques, enhancing the SEAM process, and optimizing material-process interactions. Within this project, she focuses on materi…

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Taylor-Couette simulation of Bingham Fluid Phase-field simulation of falling droplet Granular Particle Image velocimetry of jet Phase-field simulation of jet Networking with other projects Poster TRR2…

Project leaders

Geier, Martin Junior Prof. Dr. rer. nat.

He substantially contributes to model development and implementation related aspects of WPs 1-2 and will contribute to the analysis of simulation results with special focus on WP 5.

Project(s)

Modelling and Simulation of Shotcrete 3D Printing (SC3DP) Based on a Massively Parallel Multi-Phase, Multi-Component Coupled LBM-DEM Approach

Krafczyk, Manfred Prof. Dr.-Ing.

is responsible for WPs 3-5 and contributes to HPC and setup related aspects of the corresponding simulations. He advises Dr. Kutscher in conducting the simulations and the analysis of the results. He also takes responsibility for the data exchange with other projects within the TRR.

Project(s)

Modelling and Simulation of Shotcrete 3D Printing (SC3DP) Based on a Massively Parallel Multi-Phase, Multi-Component Coupled LBM-DEM Approach

Contributors

Kutscher, Konstantin Dr.-Ing.

is the lead developer of the VirtualFluids software. In this function he is indispensable for the project as a new doc. res. could not possibly extend the existing framework (>700,000 lines of code) with the new models to be developed and adapted in WP 1-4. He is also experienced in conducting massively parallel runs on THIER-0 systems and analyzing huge data sets with more than 10 degrees of free…

Project(s)

Modelling and Simulation of Shotcrete 3D Printing (SC3DP) Based on a Massively Parallel Multi-Phase, Multi-Component Coupled LBM-DEM Approach

Project Scope Website Path Planning Sensorization Networking with other projects Poster TRR277_B04_Poster_1-DFG-BegutachtungTRR277_B04_Poster_2-DFG-Begutachtung Process Control and Adaptive Path Plann…

Project leaders

Hürkamp, André Dr.-Ing.

is junior research group leader at the IWF. Together with Prof. Raatz, he is responsible for the proposed project and its coordination within the TRR 277. He guides the IWF-staff related to the project and decide about research actions in terms of numerical investigations and model reduction.

Project(s)

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

Raatz, Annika Prof. Dr.-Ing.

she is responsible for the scientific management and coordination of project B04. In addition to supervising the content of the research assistant, she supports the coordination of the work and represents the project internally and externally as head of the institute.

Project(s)

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

Contributors

Akica, Ilknur M. Sc.

is a researcher at the Institute for Machine Tools and Production Technology (IWF) at TU Braunschweig. She will be responsible for developing finite element models for use in additive manufacturing. This includes simulation of the process, investigation of the material models, and ensuring component stability. She further analyzes all data, prepares reports, presentations and publications.

Project(s)

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

Ekanayaka, Virama M. Sc.

is a doctoral researcher at the IWF. He will be developing finite element models to be used in additive manufacturing. He will lead the implementation of mathematical approaches for model order reduction and work on system sensorization. He will frequently publish the results achieved within the community.

Project(s)

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

Heeren, Hauke M. Sc.

is a doctoral researcher at the Institute for Assembly Technology and Robotics within Leibniz University Hannover. His background in mechatronics and robotics drives his work on mobile robotics. By synergizing elements from computer science, control theory, and mechanical design he enhances robotic autonomy and efficiency to enable print-while-driving

Project(s)

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

Mojaddarasil, Mohammad M. Sc.

is a doctoral researcher at the Institute for Machine Tools and Production Technology (IWF) at TU Braunschweig. He will support developing finite element models for use in additive manufacturing. This includes supporting the simulation of the process and investigation of the effect of material modelling. He further analyzes all data, prepares reports, presentations, and publications.

Project(s)

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

Figure 1: Mobile part-based AM: Fabrication scenario of a stay-in-place formwork carried out by a mobile robot. Figure 2: Two mobile robotic systems; left system is equipped with clay extrusion setup….

Project leaders

Dörfler, Kathrin Prof. Dr. sc. ETH

leads the scientific staff in the conception and execution of the research, and in questions of validation of the proposed methods. She is also responsible for the coordination of the cooperating research projects in the TRR 277. She is the Co-Spokesperson of the TRR 277. Dörfler supports Kloft as contact person for the DFG, in general public relation matters and also in representing the TRR 277 externally. Internally, Dörfler assists Kloft in the coordination between the research projects, as well as in the decisions on the financing of research tasks in the TRR 277.

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Principles of Mobile Robotics for Additive Manufacturing in Construction

Learning, Sustainability, Design: Gender-equitable introduction of AMC to the public

Central Tasks of the AMC

Contributors

Dielemans, Gido M. Sc.

is a doctoral researcher at the TT Professorship for Digital Fabrication within TUM. With background in structural design and engineering, he will develop strategies for using mobile robotic systems performing extrusion-based AM on construction sites. Fundamentally, this work is interdisciplinary, and he therefore strives for a high degree of collaboration within, but not limited to, the TRR277.

Project(s)

Principles of Mobile Robotics for Additive Manufacturing in Construction

Central Tasks of the AMC

Fleckenstein, Julia Dipl. Ing.

is a doctoral researcher at the TT Professorship for Digital Fabrication at TUM with background in architecture. In her research, she explores site-specific digital design tools for robotically fabricated real-size mono-component building envelopes. As part of her association with the AMC, she is part of the interdisciplinary teaching team for the project “From Additive Manufacturing to Architectu…

Richter, David M. Sc.

David is a civil engineer with a passion for soft- and hardware development, digital manufacturing, and prototyping. He obtained his master’s degree in civil engineering from the Technical University of Munich (TUM), with a thesis focused on the investigation of printed carbon short fibre concrete under cyclic tensile stress. Prior to that, David studied philosophy and completed his bachelor’s deg…

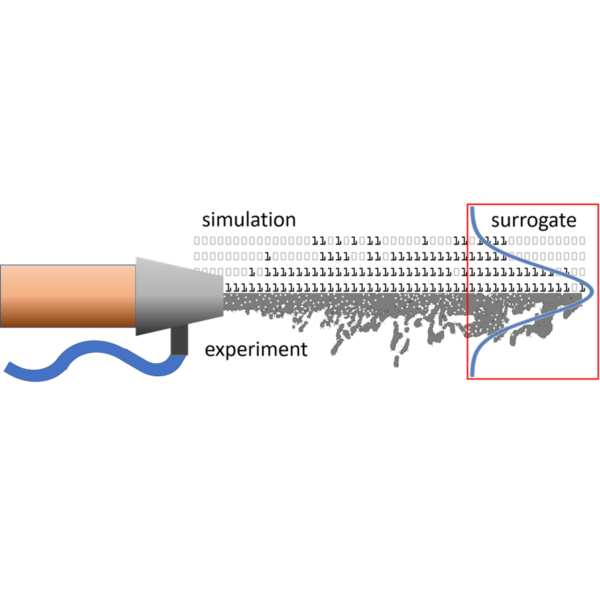

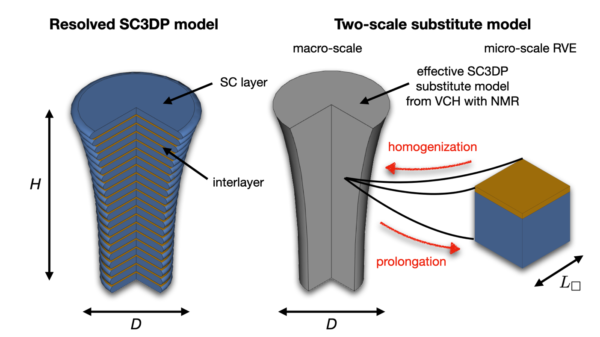

Networking with other projects Poster TRR277_B06_Poster_2-DFG-Begutachtung Material Modelling and Simulation of Deposition AM Processes on the Part Scale This project aims at providing a modell…

Project leaders

Jänicke, Ralf Prof. Dr.-Ing.

is Professor at the Institute of Applied Mechanics (IAM) –Technical University of Braunschweig . In his habilitation the focus is on computational homogenization and reduced order modelling of diffusion processes in fluid-saturated porous media.

Project(s)

Material Modelling and Simulation of Deposition AM Processes on the Part Scale

Kollmannsberger, Stefan PD. Dr.-Ing. habil.

is Professor at Bauhaus-University Weimar and is Head of the Chair of Data Science in Civil Engineering. He was head of the work group ‘Simulation in Applied Mechanics’ at the Chair of Computational Modeling and Simulation and has a fifteen year-long scientific record in that field. In this project, he is responsible for the development of simulation methods for metal based artefacts.

Project(s)

Material Modelling and Simulation of Deposition AM Processes on the Part Scale

Bridging Scales – From Geometric Part Details to Construction Elements

Contributors

La, Quoc Tuan M. Sc.

is a doctoral researcher at TU Braunschweig. He is responsible for developing material model of concrete used in additive manufacturing. His doctoral research also focuses on simulating the additive manufacturing deposition process on a part scale. Moreover, he will frequently publish the achieved results within the community.

Project(s)

Material Modelling and Simulation of Deposition AM Processes on the Part Scale

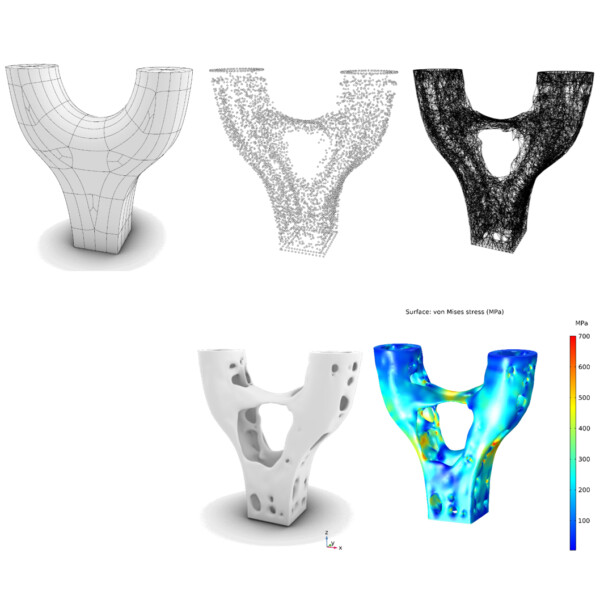

Networking with other projects Poster TRR277_C01_Poster_1-DFG-ReviewTRR277_C01_Poster_2-DFG-Review Bridging Scales – From Geometric Part Details to Construction Elements Digital models for AM involve…

Project leaders

Kollmannsberger, Stefan PD. Dr.-Ing. habil.

is Professor at Bauhaus-University Weimar and is Head of the Chair of Data Science in Civil Engineering. He was head of the work group ‘Simulation in Applied Mechanics’ at the Chair of Computational Modeling and Simulation and has a fifteen year-long scientific record in that field. In this project, he is responsible for the development of simulation methods for metal based artefacts.

Project(s)

Material Modelling and Simulation of Deposition AM Processes on the Part Scale

Bridging Scales – From Geometric Part Details to Construction Elements

Contributors

Christmann, Matti M. Sc.

is a doctoral researcher at the Chair of Data Science in Civil Engineering at Bauhaus-University Weimar. He conducts research on geometric modelling and simulation of additively manufactured (AM) parts, focusing on developing efficient and effective mechanical simulation workflows for evaluating the performance of as-built AM components. His work aims to advance the field of AM by enhancing the re…

Kopp, Philipp Dr.-Ing.

is developing efficient finite element methods for engineering applications at the Chair of Data Science in Civil Engineering of the Bauhaus-Universität Weimar. One of his research areas is the spatiotemporally adaptive resolution and numerical optimization of additive manufacturing processes. He also focusses on immersed simulations of 3D-printed geometries and on spectral element or spectral cel…

Oztoprak, Oguz M. Sc.

Oguz Oztoprak is a doctoral researcher at the Chair of Data Science in Civil Engineering at Bauhaus-University Weimar. He conducts research on geometric modelling and simulation of AM parts. More specificaly, he develops efficient and effective mechanical simulation workflows to integrate complex AM parts into building scale models.

- 1

- 2