Research Summary Report B05

Principles of Mobile Robotics for Additive Manufacturing in Construction

01.03.2022

Dielemans, Gido; Doctoral researcher,

Technical University of Munich,

Department of Architecture, TT Professorship Digital Fabrication

This research examines the architectural implications of mobile robotics for AM in construction and develops methods for their implementation. The material deposition method of clay and concrete extrusion 3D printing is used to investigate mobile part-based AM strategies, that is, to produce large objects whose size exceeds the static workspace of the robot. By implementing advanced sensor and control solutions, autonomous localization and precise manipulation techniques for mobile AM are explored. In addition, this research aims to provide scalability to AM processes by examining the use of multiple robots to collaborate on single fabrication jobs. The objective of this research is to develop mobile AM technology for its direct implementation on construction sites.

Summary

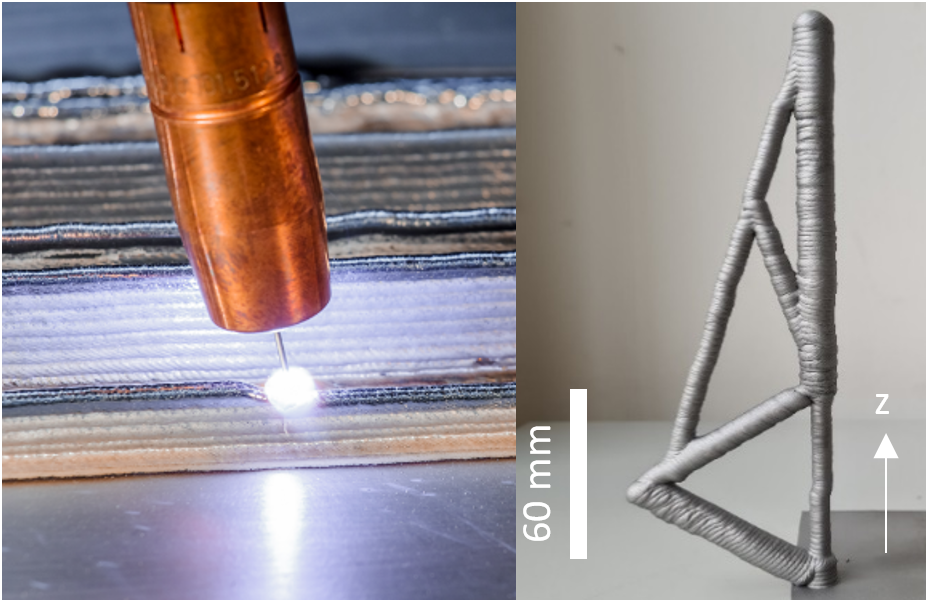

Two medium scale mobile platforms have been designed and constructed to be capable of omnidirectional ground-based movement using four steerable wheels. The platforms are equipped with a vertical linear axis, on top of which a 6DOF robotic manipulator with a range of 1.3 meters and a payload of 10kg is mounted. For initial case studies, the mobile manipulators are equipped with a clay extrusion 3D printing system, in which a clay cartridge is mounted on the 3rd link of the robot arm and connected to the extruder system mounted as an end effector via a hose. The current setup allows for material extrusion heights of 2.5m (Fig. 1).

For localization and positioning, these mobile systems rely on onboard sensors, where the localization is performed using a two tier strategy. First, global localization is performed through SLAM using a front mounted 3d LiDAR, which provides an accuracy of ±5cm for the pose of the mobile system in the work environment. This degree of accuracy does not suffice for extrusion tasks with a nozzle size of 7mm, and therefore a second tier of localization is adopted. For this, the end-effector is equipped with a 2D profile scanner that can capture the printed geometry and locate the robot in reference to the work piece.

This two tier sensing and part-based fabrication is being explored in a case study for 3d printed clay formworks for1:1 large scale concrete building components, using a mobile robotic system and a print-drive-print approach.

Current state of research short

The current project status is researching the additive manufacturing of building components on a 1:1 scale with mobile robot systems using clay extrusion 3D printing. In the experiments currently being conducted, the clay serves as a formwork for the casting of a lightweight concrete, where the clay defines the shape while the concrete applies shape stability and structural properties to the building component (Fig, 2). As the clay and the concrete do not adhere, the clay can be easily removed from the concrete after hardening and reused for a new formwork.

| Figure 2: Clay extrusion of a segment / Credit: TT Professorship Digital Fabrication, TUM |

Testing and validating the capabilities of the mobile platform in a print-drive-print approach, clay formworks are constructed in segmented parts from multiple robot locations. This requires a geometry to be segmented into parts that consider physical constraints such as end-effector collisions and the robotic manipulator range, as well as material constraints such as build-up rates and strength evolution over time.

A design-to-fabrication environment has been set up, allowing bi-directional communication with all components of the mobile robot systems and thus to control the manufacturing process directly from the architectural planning software. Manufacturing the formwork from multiple locations requires accurate localization of the robot system in relation to the building component. Within this initial case study, the two-tier localization and positioning system using on-board sensors is being evaluated to ensure accurate mobile manufacturing performance.