Research Summary Report A02

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

04.03.2022

Riegger, Felix; Doctoral researcher,

Wimmer, Andreas; Head of the research group

All: Technical University of Munich, Institute for Machine Tools and Industrial Management

The main goal of the project A02 is the implementation of reinforcement with Wire and Arc Additive Manufacturing (WAAM) in concrete elements produced by Selective Paste Intrusion (SPI) by means of a simultaneously additive manufacturing process.

The combination of SPI and WAAM is accompanied by obstacles that must be overcome to ensure the collaborated functionality. One major challenge occurs from the high energy input of WAAM (temperatures up to 1600 °C), which negatively affects the paste rheology and resulting concrete strength. Therefore, the overall goal is to minimise heat propagation into the particle bed [1].

Summary

Within A02, the working group Zaeh is researching the WAAM process for the production of reinforcements. The aim is to achieve 3D printable WAAM reinforcement with properties comparable to conventional rebars, validated through experiments and simulation.

parameters for the production of WAAM- manufactured reinforcement structures are identified, and process investigations are conducted with an experimental setup.

Within the last reporting period, branching and joining nodes were researched in detail, and different manufacturing strategies for these specific geometries were developed. Detailed robot path planning and intelligent manipulation of the contact-tip-to-work- distance (ctwd) is necessary to guarantee the collision- free production of reinforcement nodes.

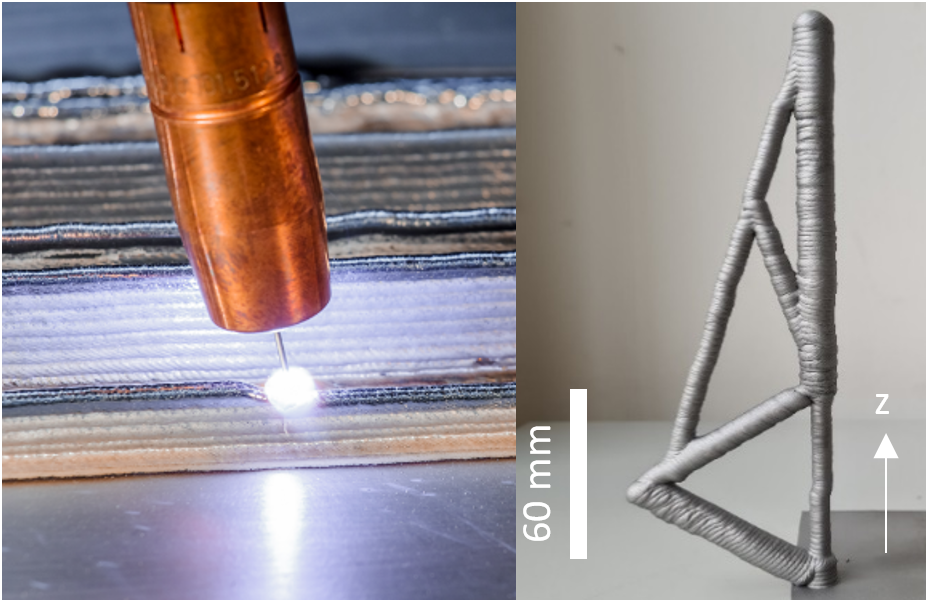

A truss system was 3D-printed (see Figure 1) to show the feasibility of branching and joining nodes and other geometrical features. Abrupt geometry transitions from smaller to larger diameters, generating unsupported component areas, were demonstrated to be producible, as well as inclined bars up to an overhang angle of 60 °.

A numerical process model was created to reduce the experimental effort and to extend the understanding of the process. This model describes the temperature distribution and development in the WAAM- manufactured component and considers the influences of specifically cooled areas. Thus, different cooling strategies can be investigated and evaluated by simulation.

Particular attention is paid to the boundary conditions resulting from the desired simultaneous process combination of WAAM and SPI.

Current state of research

In the combined SPI+WAAM process, the main part of the reinforcements produced with WAAM will be encased in concrete. Therefore, a directed and precise cooling of the reinforcing bars is necessary. A robot-guided cooling system is being developed for this purpose while different cooling strategies are compared. One of these cooling strategies is spray water cooling. The experimental setup of a preliminary experiment is shown in Figure 2.

As depicted in Figure 1, truss structures include joining and branching nodes. For the accurate and collision-free manufacturing of these geometric features, special strategies are developed. To avoid collisions between the welding torch and the manufactured structure the ctwd is increased in the area of the nodes. Also, the order of deposition is varied for branching nodes in a specific manner, since the electric arc can be deflected when deposition points are spatially close to each other. This leads to shape deviations if no countermeasures are taken.

A collaboration within the AMC was initiated to look into topology-optimised reinforced concrete structures. The optimised structures may significantly increase the potential for the Additive Manufacturing of reinforced concrete.