Research Summary Report C03

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

[11.03.2022]

Briels, David; doctoral researcher, david.briels@tum.de Nouman, Ahmad; doctoral researcher, ahmad.nouman@tum.de Auer, Thomas; PL, thomas.auer@tum.de Technical University of Munich, TUM School of Engineering and Design, Chair of Building Technology and Climate Responsive Design

This research aims to develop and test additively manufactured building components that integrate multiple passive and active functions to improve building operation and environmental quality. The performative features are directly incorporated into building components to utilize the potential of AM. Thus, we aim to enhance recyclability and performance by shifting the approach from complex multi-layered and multi-material to mono-material and multi-functional components. These components are developed and optimized through a simulation-based parametric design process for integrated performative functions. Thereby, this research aims for high robustness through functional integration in the design and fabrication process and intends to improve building performance.

Summary

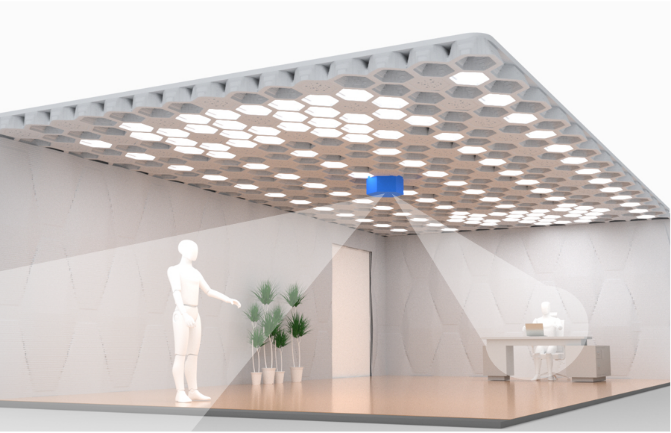

The approach of integrating passive and active functions into AM building components allows enhanced user comfort via the deployment of sensors, smart controls, and decentralized functionalities, such as heating, cooling, ventilation, and lighting (see Fig 1). The functionalities can thus be distributed and utilized locally and adjusted individually by the users, resulting in optimum energy efficiency and robustness. This can be one of the most significant benefit of functional integration via AM.

In order to achieve this, three parametric optimization goals will be synchronized and streamlined: a) geometric optimization to achieve resource efficiency, b) optimization of individual functionalities to increase performance (energy use and comfort), and c) optimization of the infrastructure and supply network of all functions for efficient space usage. This approach will reveal its full potential especially for concrete slabs in office buildings due to their high functional density and complexity.

Current state of research short

The AM extrusion process combined with lightweight concrete can produce mono-material and multi-functional elements with high thermal performance and low resource consumption. So far, a prototypical wall element with an internal closed cellular structure was designed and manufactured using a simulation-based parametric design process. The theoretical and actual thermal performance of the wall element were evaluated through an analytical approach, 2D and 3D heat flux simulations (see Fig 2), as well as experimental heat flux measurements.

As a next step, a “breathing murocaust wall” with a further improved effective U-value is being developed. To achieve this, heating and cooling loads are shifted in an integrated closed air channel system using pumping effects driven by thermal buoyancy and controlled by smart thermo-responsive flaps.