Research Summary Report of A08

Structural Timber by Individual Layer Fabrication (ILF)

[06.01.2023]

Asshoff, Carsten; Doctoral researcher; carsten.asshoff@wki.fraunhofer.de

Fraunhofer Institute for Wood Research

Wilhelm-Klauditz-Institut WKI

The main goal of the project ’A08 – Structural Timber by Individual Layer Fabrication (ILF)’ is to develop a process to additively manufacture large-scale, wood composite objects with a maximum content of wood material and strength values suited for applications in construction. In the course of the project multiple process variants and material combinations are explored. For this, the necessary machinery is developed in iterative steps and the mechanical properties of the resulting objects as well as the geometric capacity of the processes are investigated. Finally, multiple demonstrators are fabricated for showcase purposes.

Summary

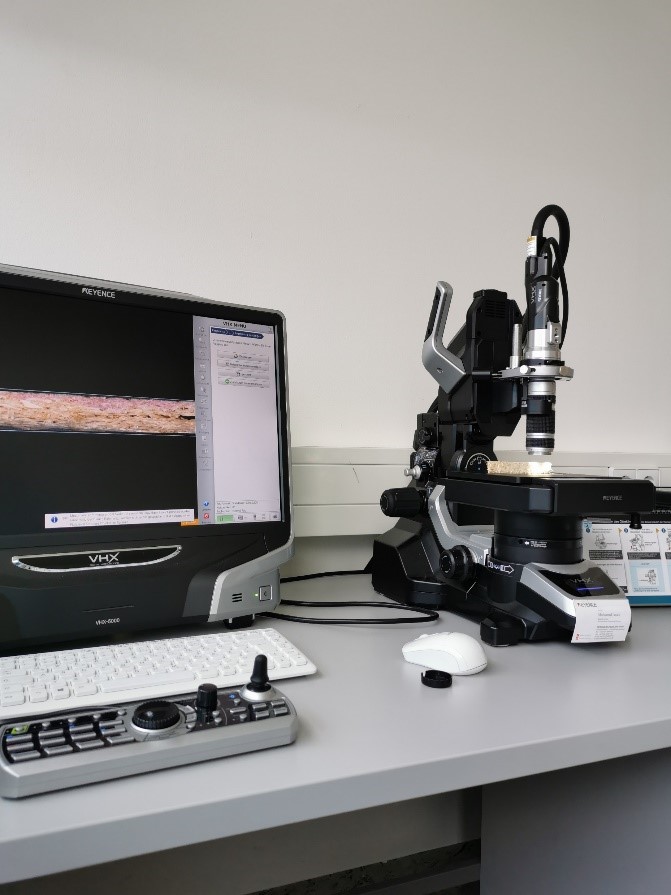

Working group Bunzel is researching the process behaviour and properties of the adhesive and wood particles, which are to be used for the ILF process. For contour accuracy the adhesive is applied onto the wood chips from above and locally, where it is required in terms of component geometry. The adhesive must be applied in that manner that after pressing it bonds the wood chips by its own distribution flow only where the contour requires it. Here, the contour for an individual layer (IL) is defined by its geometry in the plane and depth. How much adhesive must be applied locally that it bonds the particles fully are carried out and was microscopically detected (Fig. 1). It depends on many factors like adhesive type (rheology and surface tension), adhesive amount, particle size, density, pressing temperature, dispense technique and patter.

Current state of research

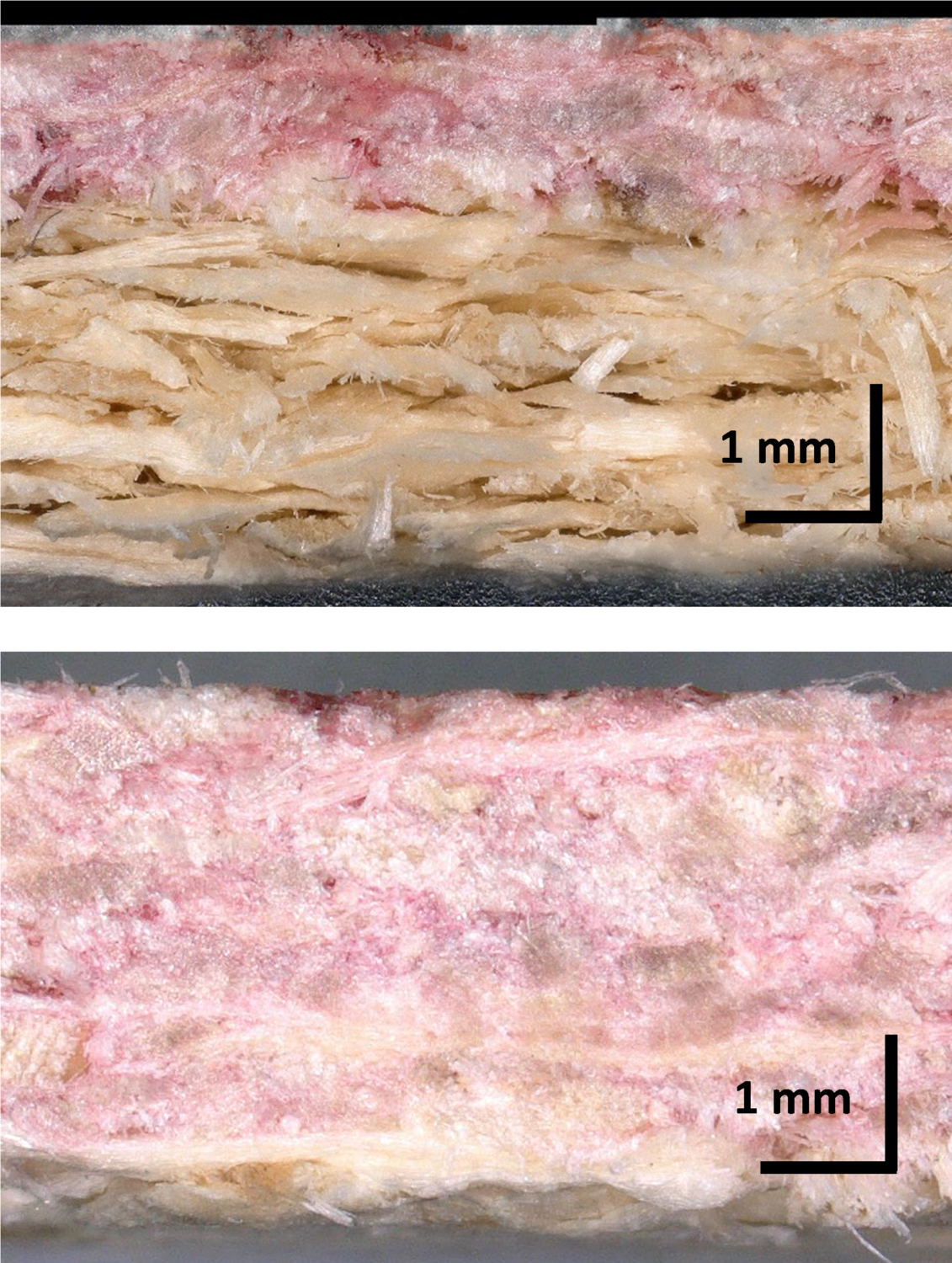

Knowledge of the distribution behavior in plane and intrusion in depth is necessary to produce the desired contour of each layer. Therefore, different adhesive types (rheology and surface tension), adhesive amounts, particle sizes, densities and dispense patters are investigated and microscopely valued. An IL with adhesive not fully penetrated into the wood particle layer is shown in Fig. 2 (top). For better contrast the adhesive was colored red. The adhesive amount of the other IL of Fig. 2 (bottom) was enough which leads in fully intruded adhesive in the wood particle layer.