Research Summary Report A06

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience

[16.09.2022]

Wenzler, David; Doctoral researcher; david.wenzler@tum.de

Technical University of Munich, Institute for Machine Tools and Industrial Management

Diller, Johannes; Doctoral researcher; johannes.diller@tum.de,

Siebert, Dorina; Doctoral researcher; dorina.siebert@tum.de

Technical University of Munich, Chair of Metal Structures

The project A06 aims to explore and evaluate the factors influencing the manufacturing of safe and durable structural steel elements by Powder Bed Fusion of Metals using a Laser Beam (PBF-LB/M). Thereby, the PBF-LB/M process, the post-treatment, and the geometrical aspects in terms of microstructure and mechanical properties are investigated and correlations are determined. In the first funding period, the project is focused on analyzing small-scale specimens as well as complex facade elements with multiaxial stress states. Based on the results, a first methodology for a qualified design of safe and durable structural steel elements by means of additive manufacturing (AM) is derived.

In the construction industry, steel parts have to withstand a large range of temperatures, e.g. from arctic areas at -60 °C to 850 °C in fire situations. Indeed, 316L transforms its austenitic microstructure to martensite at -60 °C. This results in an embrittlement which is to avoid in construction industry especially with fatigue loads. Therefore, Cyclic loaded 316L may have less fatigue resistance at lower temperatures. For clarification fatigue testing of PBF-LB/M manufactured 316L has to be conducted at low temperatures.

Current state of research

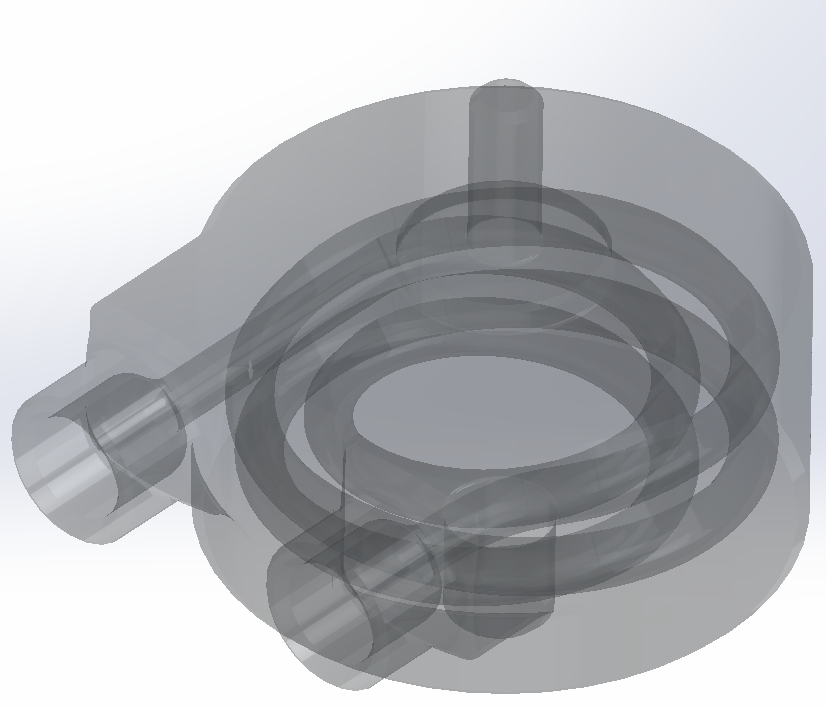

Currently, a new test setup is being planned for fatigue testing at cryogenic temperatures. To this purpose, a cryogenic system is installed in between the fatigue testing machine. The load cell however must not be affected by the temperature change. Therefore, a cooling unit was designed with cooling channels and optimized for the PBF-LB/M manufacturing process. Fig. 1 shows the design of the cooling unit.

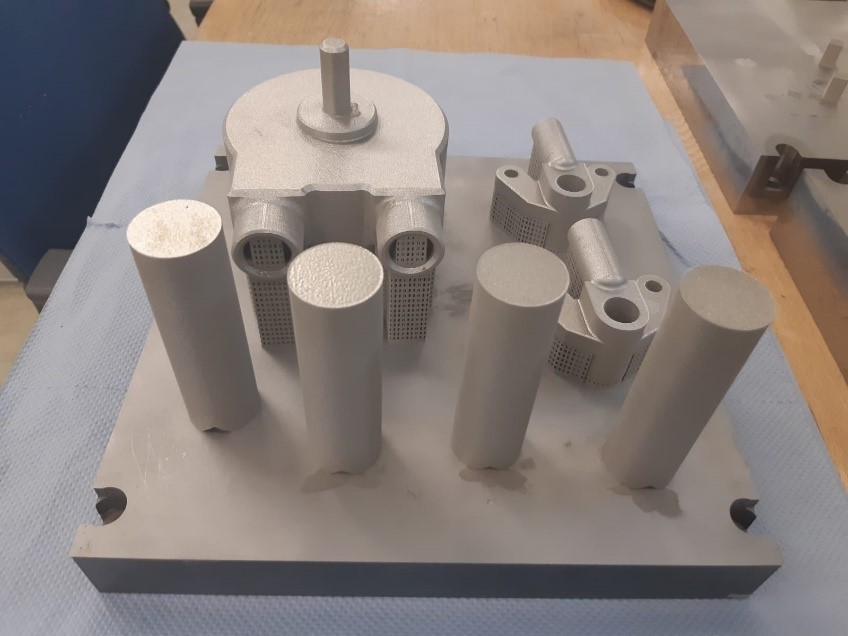

Droplet-shaped cooling channels were designed into the part. The droplet shape makes it possible to use no support structure inside the part which would be impossible to remove after the manufacturing. A water-cooled heat exchanger will then be installed to the part which regulates the temperature of the cooling unit. This reduces the risk of falsified measured data of the load cell during the fatigue testing. Fig. 2 shows the PBF-LB/M-manufactured cooling unit on the build platform. This design can only be manufactured via PBF-LB/M.

The PBF-LB/M-manufactured 316L fatigue specimens will be cooled down to a desired temperature in a box with liquid nitrogen (LN2). The temperature of the specimen will be measured via a thermocouple and the LN2 flow in the cryogenic box will be adapted if necessary.