Project A 07

Networking with other projects

Poster

TRR277_A07_Poster_1-DFG-Begutachtung

TRR277_A07_Poster_2-DFG-Begutachtung

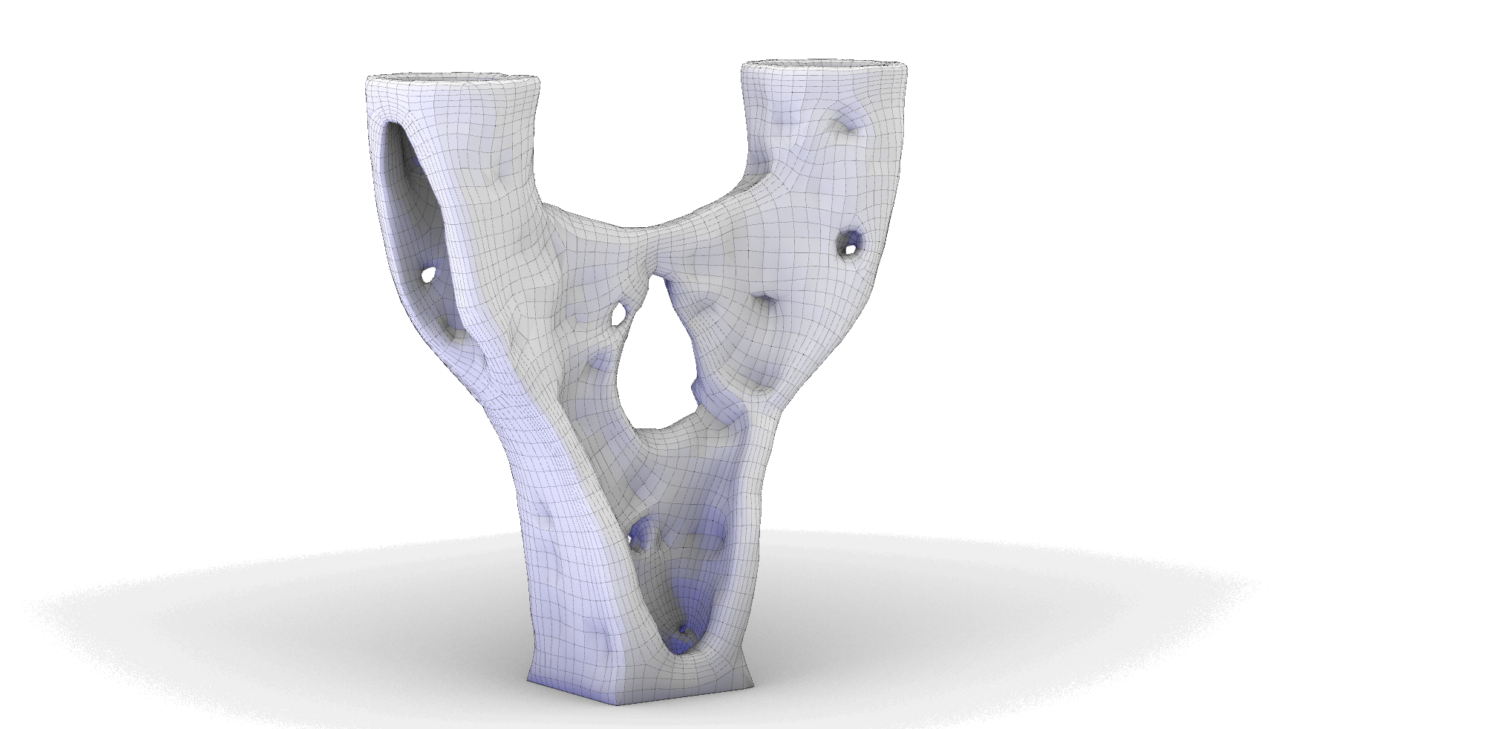

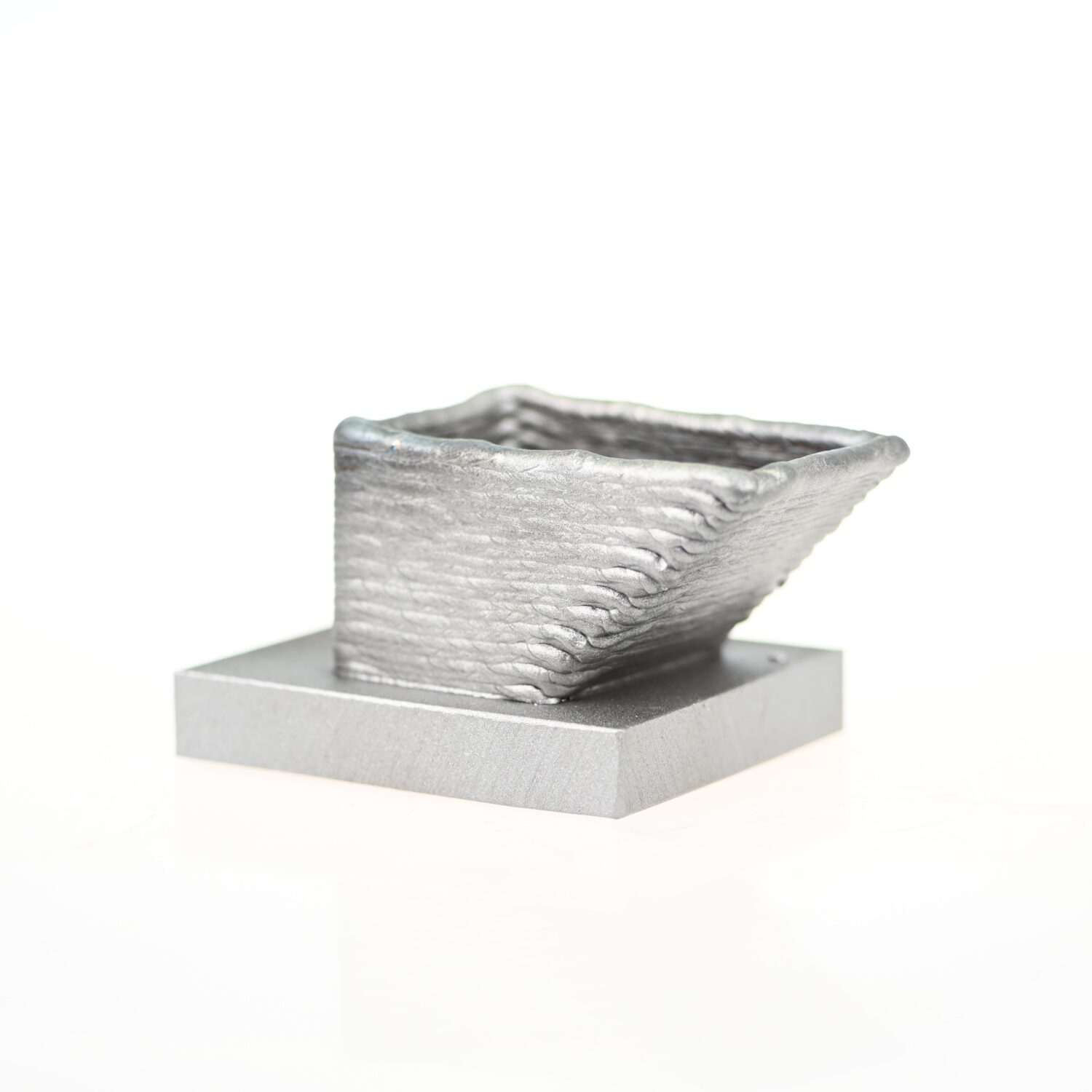

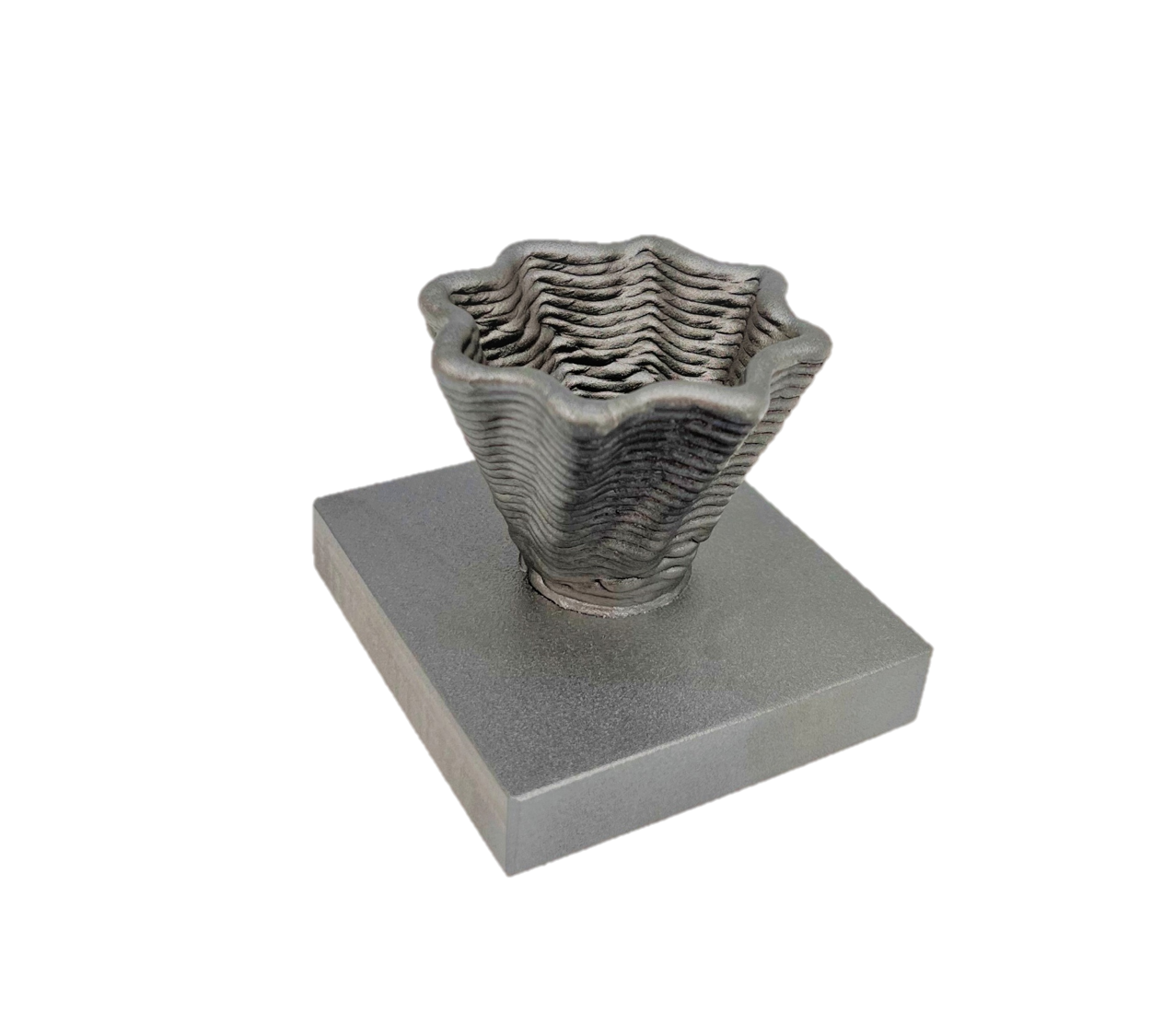

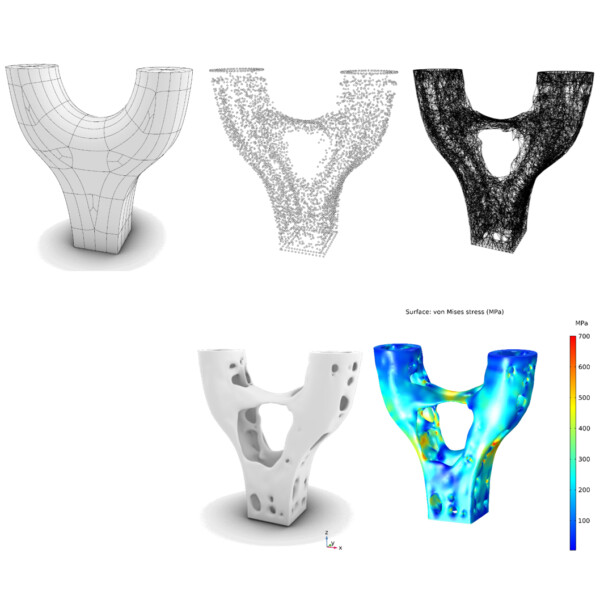

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Project A07 investigates structural design, WAAM methods and component testing of complex, large-scale, individualized steel components. The objective is to connect conventionally manufactured steel components and semi-finished products with additively manufactured, complex steel components, like connection nodes or anchorage structures for concrete. The research program is based on innovative design and manufacturing methodologies that take both additive manufacturing parameters and material properties into account. The evaluation of the WAAM components follows a novel test method, which considers potentially anisotropic component behavior, surface topographies, geometric irregularities and residual stresses in addition to the relevant material properties.

Objective

The objective of TP A07 is the design, the manufacturing and the testing of force flow optimized steel nodes for use in construction.

Approach

A new method is developed to design force flow optimized steel nodes as connectors between semi-finished parts and anchorage structures considering the manufacturing possibilities of the WAAM-process and the resulting material behaviour. The manufacturing possibilities will be identified by case study demonstrators which represent occurring features of the designed node. The produced parts are characterized regarding their mechanical properties. For that an advanced material testing method is applied to evaluate the potentially anisotropic material behaviour. With buckling tests on case study demonstrators the component behaviour will be investigated.

Networking with other projects

- A04: The bond behavior of WAAM-rebars in concrete is investigated. Bars with varying cross sections were produced in order to maintain different surface topographies.

- A06: The possibilities of combining the two AM processes LPBF and WAAM were investigated by conducting tensile tests and characterizing the fusion zone

- C04: coordination of a structure for the digital twin and management of input data