Research Summary Report of C02

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces

[19.12.2025]

Richter, Christiane; Researcher, christiane.richter@tum.de

Prof. Dr. D`Acunto, Pierluigi; Project leader, pierluigi.dacunto@tum.de

TUM, Professorship of Structural Design (SD)

Main Goal

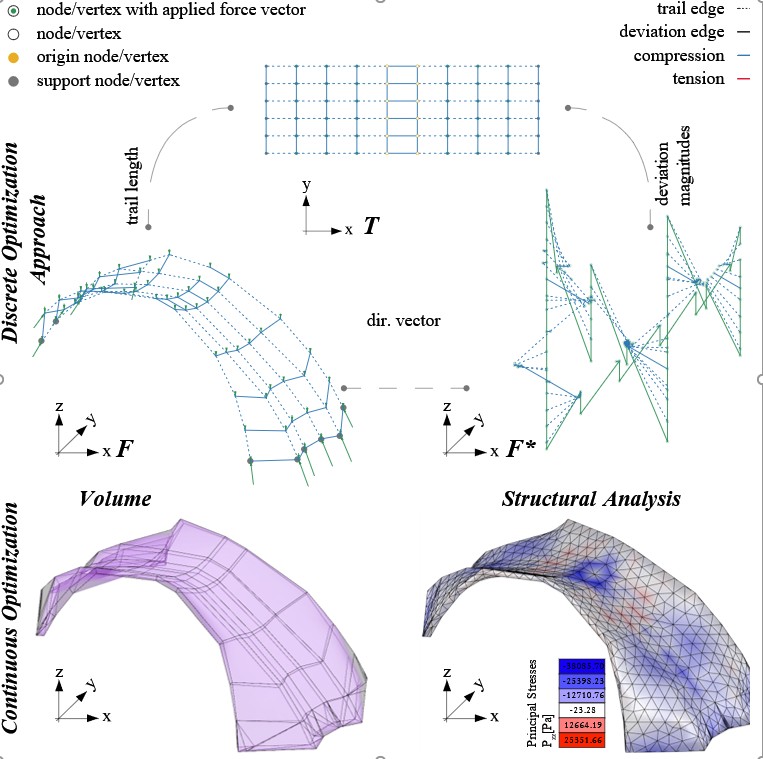

Current building practices often adopt a sequential design approach, where architectural, structural, and fabrication aspects are addressed independently, resulting in excessive material consumption. The CO2 project aims to establish a Holistic Design Framework integrating the above-mentioned aspects. Within this framework, additive manufacturing facilitates structural optimization by enabling the production of bespoke geometries for an effective use of material resources. Departing from the conventional sequential approach, the HDF concurrently integrates low-fidelity Discrete Optimization Approaches and high-fidelity Continuum-based Optimization Approaches (multi-fidelity). The HDF tackles a range of additive manufacturing processes by operating across different scales (multi-scale) and accommodating diverse materials (multi-material).

The C02 project develops a Holistic Design Framework (HDF) for Additive Manufacturing in Construction (AMC) that couples rapid, equilibrium-based form-finding with continuum-based mechanical evaluation in a single multi-fidelity workflow. Discrete Optimization Approaches (DOA), implemented through graphic-statics-based methods, are employed for efficient exploration of structurally admissible designs, while Continuum-based Optimization Approaches (COA) using Finite Element Analysis (FEA) provide high-fidelity assessment of structural performance. In the current project phase, these two modelling paradigms have been systematically connected, enabling a coherent transition from exploratory form generation to mechanically informed design refinement.

Within this workflow, large sets of feasible form-found geometries can be generated efficiently and screened based on geometric and force-based criteria. Selected alternatives are then mapped into volumetric models and evaluated through finite element simulations, allowing for a comparison of variants with respect to different criteria, such as tensile strain energy and local stress concentrations. This iterative DOA–COA exchange provides deeper insight into how early equilibrium decisions influence continuum-level performance, forming a robust bridge between conceptual design and detailed structural assessment.

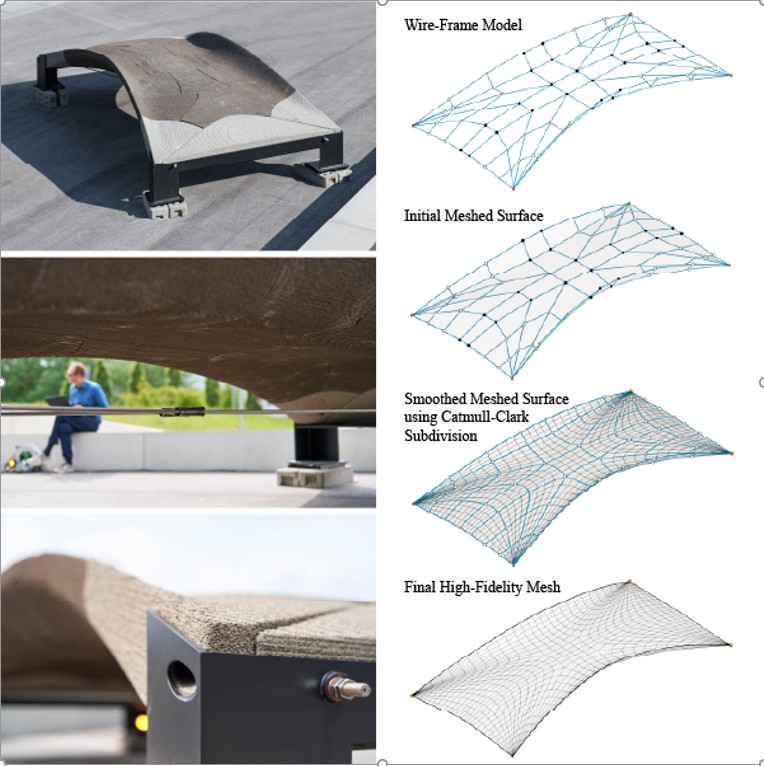

Recent investigations focus on applying this methodology to shell-like structures, exemplified by an arching bridge demonstrator, as a logical continuation of the Bridge-the-Gap project (Fig. 1, Fig. 2). Here, a compression-dominant shell structure is generated throughout the application of the HDF: the form-found wireframe is transformed into a volumetric representation. Subsequent FEA allows to enhance the mechanical evaluation of the structure and to assess how closely discrete solutions reflect continuous mechanical behavior.

In parallel, the subproject is working closely with A-projects to integrate additive manufacturing constraints into the design workflow. By considering process- and material-specific limitations across extrusion-based and particle-bed systems, as well as materials such as concrete, metal, and earth, the framework is being prepared to accommodate a wide range of fabrication scenarios within the AMC.

Together, these developments move the HDF closer to applicability in real demonstrators, supporting structurally optimized and fabrication-aware solutions for the built environment.

In the current phase, we have successfully established a first combined workflow that links equilibrium-based form-finding with continuum analysis. This setup allows us to explore synergies between the two approaches while preserving their respective advantages: the speed and geometric flexibility of discrete form finding on one side, and the mechanical accuracy of finite-element evaluation on the other. The combination forms the basis for assessing how early design decisions translate into structural performance and it’s implementation is now being tested on various structural typologies, including arching bridges and shell-like pavilion geometries. These studies help identify which geometric, mechanical, and fabrication-related parameters become relevant when moving from simple wireframe models to continuous, volumetric representations.

A particular focus lies on shell-like structures dominated by membrane stresses. Here, first ideas are being investigated on how force patterns from the discrete form-finding stage may relate to principal stress trajectories in the continuous model. These exploratory mapping approaches aim to better understand how discrete and continuous representations interact and where meaningful relationships may emerge.

Overall, the project is progressing from conceptual integration toward systematic testing across multiple design cases.