Research Summary Report of B04

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

[07.02.2024]

Raatz, Annika;

raatz@match.uni-hannover.de

LUH, Institute of Assembly Technology and Robotics

Lachmayer, Lukas;

lachmayer@match.uni-hannover.de

LUH, Institute of Assembly Technology and Robotics

Heeren, Hauke;

heeren@match.uni-hannover.de

LUH, Institute of Assembly Technology and Robotics

Main Goal

The research of project B04 is dedicated to extending the current state-of-the-art path planning and process control algorithms for concrete-based additive manufacturing. The objective is to enable reproducible production of multi-material components utilizing mobile robot systems in motion, known as print-while-driving. Achieving this requires precise localization, considering system dynamics, such as acceleration and jerk limitations, as well as accounting for varying material properties and building installation during the trajectory generation and the printing with mobile robot-based systems.

Summary

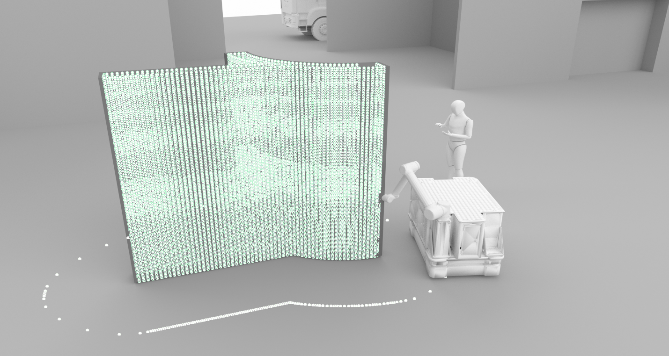

The initial focus during the 2nd funding period is laid on extending path planning algorithms and process simulations by including tailored material properties and integrating objects such as reinforcement bars, pipes or other building installations to calculate production paths for autonomous mobile robot systems (AMRs). Since such mobile systems are mostly controlled by velocities to allow versatile control, the first step requires transforming path planning algorithms into trajectory planners and, thus, assigning time stamps to each of the material application points. We therefore extend the current Rhino/Grasshopper planing environment to simulate mobile robot behaviour, shown in Fig. 1. Our current investigations thereby focus on deriving a valid platform trajectory using the previously designed print path. For the sample shown in Fig. 1., the path points for the platform were generated using iterative offset curve generation in combination with path smoothing to ensure, the MIR 600 platform will stay within the given linear and rotational acceleration limitations.

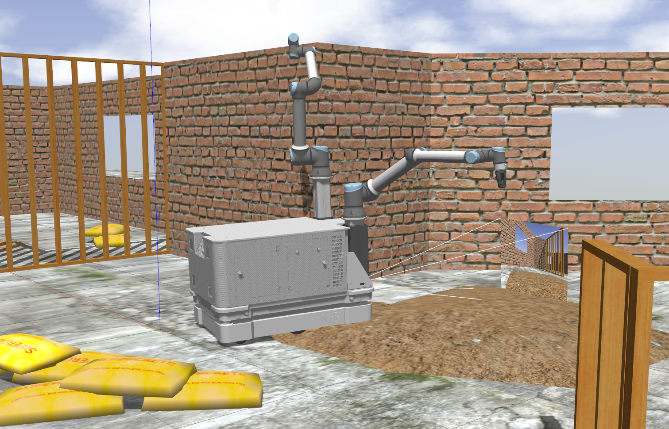

Aside from trajectory generation, initial experiments revealed insufficient onboard AMR localisation, common within the range of centimetres, as a major challenge in denying continuous layer stacking during mobile robot motion. Solving this, however, is fundamental to enable the investigation and application of the expanded path planning and process control for autonomous mobile robot printers. Thus, B04 is enhancing localisation and control capabilities. To this end, we are currently developing a comprehensive simulation of mobile platforms on construction sites. A ROS Gazebo environment is being used for this purpose to also allow for robot controller design and localization tests. Varying maps, such as the one shown in Figure 2, enable research on the influences of floor conditions.

After enhancing print path planning and simulation algorithms, as well as localization and control algorithms, the next challenge within B04 is ensuring printing as planned throughout the manufacturing process. During the 1st funding period, this was achieved by simulation-based compensation of the time-dependent material properties with interlayer waiting times and compensation of environmental influences through in-line measurement and process control. However, existing sensors and control approaches cannot deal with varying material properties or objects within the print path. B04 therefore, examines which objects must be explicitly taken into account in the path planning and which are compensated for by the state-of-art online process control. As a result, the process control system will be extended to recognize objects within the path and constantly acquire material properties to identify and correct arising deviations.

Current state of research

The current research work is mostly concerned with deriving a suitable trajectory from the print paths generated during the first funding period. In addition to the targeted investigation of offset curves, an iterative approach using kinodynamics is also being investigated. Currently, generated trajectories are being tested as part of 3D simulations within the Rhino CAD environment and using the ROS framework.