Research Summary Report of A01

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

[04.12.2024]

M. Sc. Friedrich Herding Researcher, friedrich.herding@tum.de

Prof. Dr.-Ing. Dirk Lowke Project leader, lowke@tum.de

TU Munich (TUM), Chair of Binder Jetting Technology

Our main research objective is the fundamental understanding of the material-process interactions in particle bed 3D printing (PB3DP) by Selective Cement Activation (SCA). This will allow for the manufacturing of concrete elements with high mechanical strength and dimensional accuracy. Besides we also investigate different ways of reinforcement integration, which is crucial for the manufacturing of load-bearing building components.

Summary

Selective Cement Activation (SCA) is a particle bed 3D printing technique that offers the possibility to precisely manufacture free-form building elements with a high degree of complexity and surface quality. In SCA, the particle mixture mainly consists of sand and cement. After being scattered into the build chamber, the particle mix is smoothed and subsequently compacted by a roller. Then, the cement is selectively activated by precisely jetting water onto the particle bed. Due to the lack of formwork, the water is able to flow out of the designated volume into the surrounding particle bed. Especially at the bottom of printed objects, the formation of a so-called ‘elephant foot’ was observed before, compare Lowke et al. 2020. Expanding upon initial findings, the aim is to further improve the dimensional accuracy by vertically adjusting the water content over height to account for the often observed uneven dimensional deviations across the height of a component printed with SCA.

Current state of research

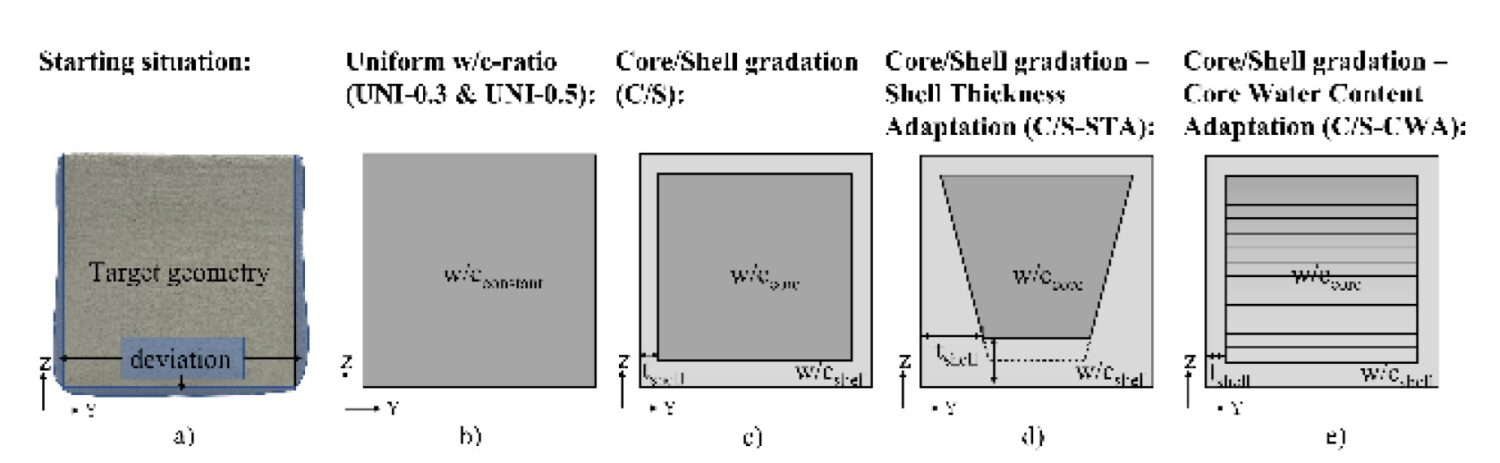

In a recent study, Herding and Lowke (2024) investigated the effect of a w/c-ratio gradation on the dimensional accuracy and the compressive strength of SCA-printed specimens. By dividing the object into an outer shell area with a lower water content and an inner core area with a higher water content, the water content is adapted over height. Four different approaches were tested, compare Figure 1. The mentioned approaches include the use of a uniform w/c ratio (UNI), a core-shell gradation with a constant shell thickness (C/S), an adaptation of shell thickness (C/S-STA) to reduce the water content in the lower area, and a stepwise adjustment of the core w/c-ratio (C/S-CWA) to optimize the mechanical properties and dimensional accuracy of the components.

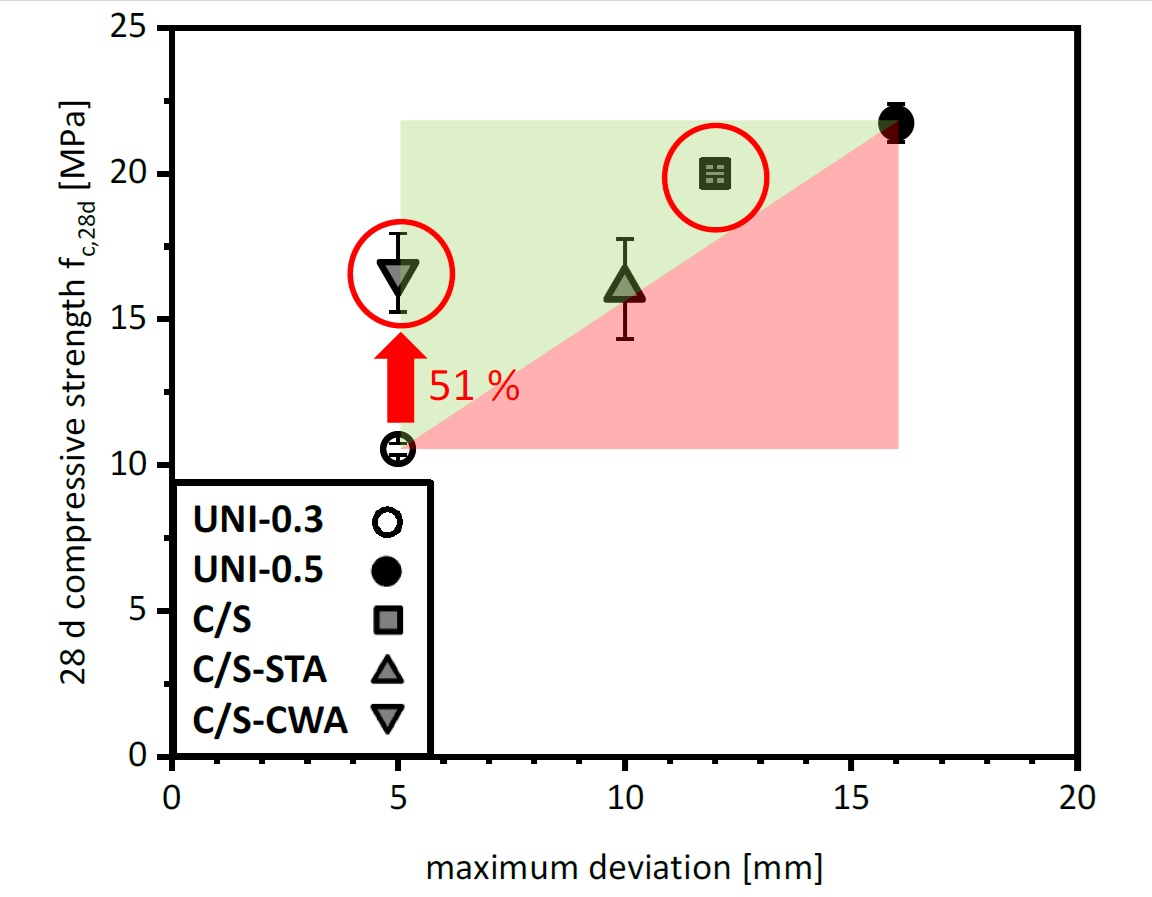

The results of the study indicate that the concept of graded w/c-ratios is effective. The dimensional accuracy of w/c-ratio graded specimens (C/S, C/S-STA, and C/S-CWA) significantly increased compared with specimens printed with a high uniform w/c-ratio of 0.5 (UNI-0.5), compare Figure 2. The C/S-CWA specimens (adapted core water content) even had similar maximum horizontal deviations from the target geometry as the specimens printed with a constant low w/c-ratio of 0.3 (UNI-0.3) while having 51 % higher compressive strength.

Current publications

Lowke et al., “Particle bed 3D printing by selective cement activation – Applications, material and process technology,” Cement and Concrete Research, no. 134, 2020

Herding and Lowke, (2024), Improving the Dimensional Accuracy in Selective Cement Activation by w/c-Ratio Gradation. In: Lowke, D., Freund, N., Böhler, D., Herding, F. (eds) Fourth RILEM International Conference on Concrete and Digital Fabrication. DC 2024. RILEM Bookseries, vol 53. Springer, Cham. https://doi.org/10.1007/978-3-031-70031-6_43

Figure 1: a) Photo of an actual printed cube with highlighted shape of the target geometry as well as the deviations (blue) and illustrations of different w/c-ratio grading concepts in SCA, with b) uniform w/c-ratio (UNI), c) core/shell gradation (C/S) with a constant shell thickness (tshell), d) core/shell gradation with a shell thickness adaptation (C/S-STA), and e) core/shell gradation with a core water content adaptation (C/S-CWA) / Credit: Herding et al., 4th Digital Concrete 2024

Figure 2: Relation between28 d compressive strength and max. deviation for the different printing concepts. The green area marks the region in the diagram with an increase in the relation between max. deviation and compressive strength compared to the references. The C/S and C/S-CWA approaches are highlighted with red cyrcles. / Credit: Herding and Lowke, 4th Digital Concrete 2024

Figure 3: Shape and topology-optimised slab element printed with SCA / Credit: Wüchner et al., 4th Digital Concrete 2024

Water etching process in the particle bed printer/ Credit: Friedrich Herding