Research Summary Report of A06

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience

[08.08.2025]

Suchowerchov, Julia; Doctoral Researcher, julia.suchowerchov@tum.de

Technical University of Munich, Institute for Machine Tools and Industrial Management

Blankenhagen, Jakob; Doctoral Researcher, jakob.blankenhagen@tum.de

Technical University of Munich, Chair of Metal Structures

Summary

The project A06 aims to develop a methodology for producing safe and functional structural steel elements for the construction industry using laser powder bed fusion (LPBF). The LPBF steel Printdur HSA® will be qualified by using and transferring methodologies from the first funding period. The prediction of fatigue behaviour based on process monitoring data and machine learning will be explored. Lattice structures will be used to tailor the stiffness of the steel elements. These complex LPBF parts will be integrated into large-scale structures, and their joining with conventional construction steel will be investigated. Data for a reliable life cycle assessment of these LPBF parts will be collected during the project.

Current state of research:

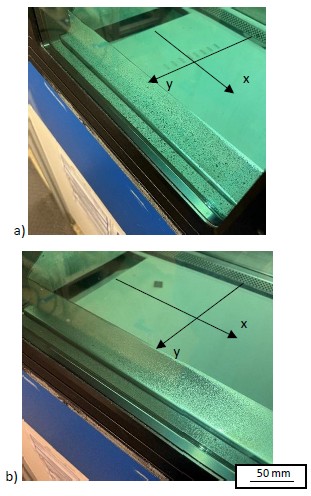

After gaining a fundamental understanding of the new material, Printdur HSA®, a paramter study was conducted in which specimens were produced using varying scan speeds and laser powers. The hatch distance was kept constant across all samples. The initial specimens were manufactured under a nitrogen shielding gas atmosphere. During fabrication, contamination of the build chamber and the recirculating filter system was observed due to significant soot formation and spatter. In Fig. 1 a), the solidified spatter can be seen on the inside of the door in the build chamber.

Subsequently, samples of 20 small cubes and exemplary hollow parts were produced by means of LPBF using argon as the inert gas. Thereafter, the contamination and the part quality were investigated.

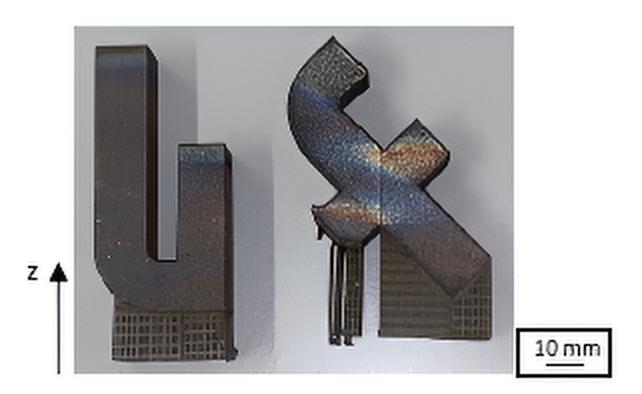

The manufacturing process with an argon atmosphere showed less contamination of the build chamber and filter, as can be seen in Fig. 1 b). There was almost no spatter, and minimal soot adhesion in the build chamber. In contrast to the cube specimens, the printed hollow parts (see Fig. 2) exhibited significant discolouration in the areas of overhangs and corners. The temper colours indicate overheating and surface oxidation, potentially caused by suboptimal process parameters in the overhang areas. Insufficient interlayer waiting time promotes the formation of thick oxide layers on the surface of each deposited layer. As shown in the literature, the oxide layer reduces the corrosion resistance of the part [1]. Further investigations regarding the influence of the interlayer waiting time on the printing of geometries with different overhangs and thicknesses should be conducted for Printdur HSA®.

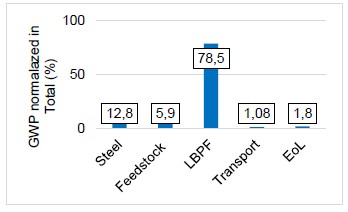

According to work package five, a life cycle analysis of an LPBF-manufactured node was performed. The necessary data regarding fabrication were gained through measurements of the electricity and the gas consumption, as well as the material usage on the machine EOS M280. The study compared LPBF with conventional manufacturing (CM), particularly casting followed by milling.

The environmental impact was evaluated in terms of the global warming potential (GWP), which is indicated in kilograms CO2-equivalent. The results for the cradle-to-grave analysis, see Fig. 3, of the steel node manufactured via LPBF showed that 78.5 % of the GWP arose during the fabrication phase. Within the cradle-to-gate framework, in-processing accounted for 79.5 % of the GWP, with electricity consumption being the primary driver of the environmental impact. The enhanced process parameters reduced the cradle-to-gate GWP by approximately 30 %, while suboptimal parameters resulted in a 146 % increase. Substituting nitrogen with argon during in-processing led to a 72 % increase in the GWP for the cradle-to-gate analysis. The cradle-to-gate analysis showed that manufacturing one steel node produced 18.0 kg CO2-eq using CM and 16.8 kg CO2-eq with LPBF. The study demonstrated that topology optimisation contributes to lower CO2 emissions compared to manufacturing by CM, provided that a significant reduction in mass is achieved.