Research Summary Report of B04

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

[18.12.2025]

Heeren, Hauke; Researcher,heeren@match.uni-hannover.de

Lachmayer, Lukas; Resarcher, lachmayer@match.uni-hannover.de

Prof. Dr. Annika Raatz; Project leader, raatz@match.uni-hannover.de

LUH, Institute of Assembly Technology and Robotics

Main Goal

The research of project B04 is dedicated to extending the current state-of-the-art trajectory planning and process control algorithms for concrete-based additive manufacturing. The objective is to enable reproducible production of multi-material components utilizing mobile robot systems in motion, known as Print-While-Drive. Achieving this requires precise localization, considering system dynamics, such as acceleration and jerk limitations, as well as accounting for varying material properties and building installation during the trajectory planning, and also when printing with mobile robot-based systems.

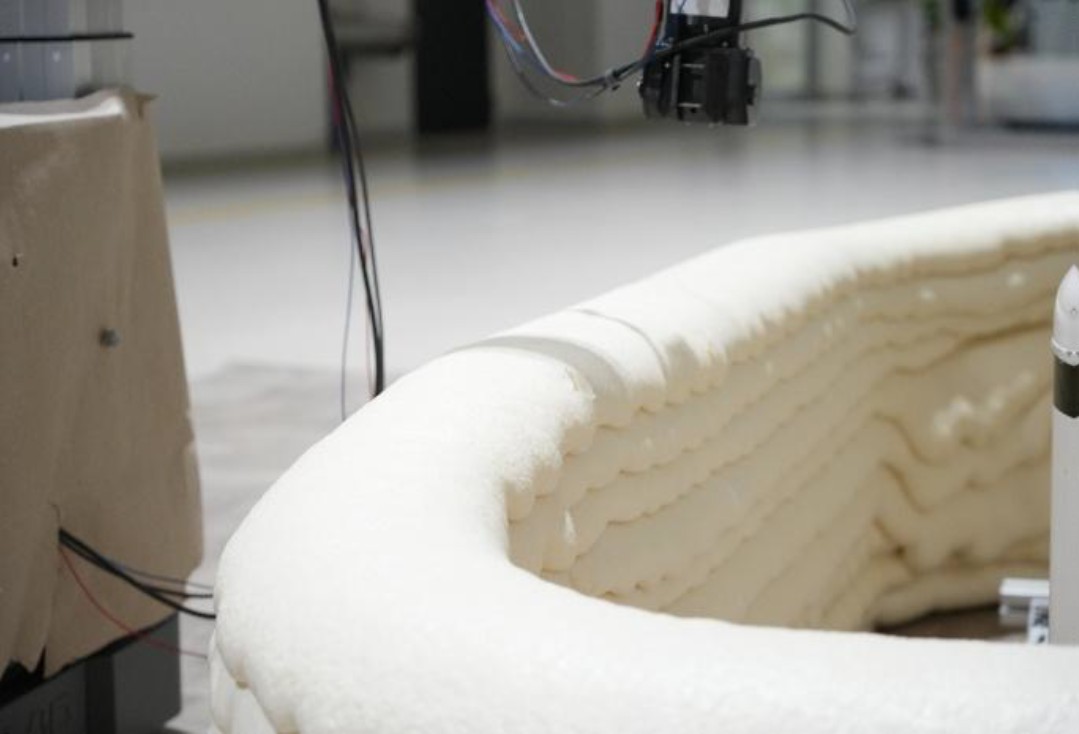

Multiple control approaches for synchronized trajectory following of the mobile base and nozzle were implemented. Several layers were printed reliably, and these specimens serve as testbeds for advancing controllers tailored to Print-While-Drive, including strand height and width regulation, now enhanced by multi-material flow control to emulate admixture dosing using the foam substitute.

Separately, a new tracked mobile robot platform with spring–damper suspension is now available. This platform is a distinct development intended for research into compensation of nozzle movement due to uneven terrain and dynamic influences typical of construction sites. It enables systematic studies of terrain-induced disturbances and control strategies.

For more efficient experimentation, a graphical user interface has been developed to configure, visualize, and log motion and process settings. Collectively, these developments advance robust, dynamically feasible trajectory generation and execution and bring the demonstrator closer to reproducible, multi-material printing in motion while reducing reliance on external tracking during operation.

Since the last report, we moved from simulation to controlled field tests of Print-While-Drive using kino-dynamic offline trajectories with coordinated nozzle and robot-pose control. In this Print-While-Drive context, multiple controllers for base and end-effector trajectory following have been designed and show promising results in first tests.

In a separate hardware line, a tracked platform with spring–damper components was introduced to enable targeted studies on compensation for uneven ground and dynamic disturbances. This platform is dedicated to research on terrain-induced nozzle motion and will support future control development. The new mobile platform is not part of the current Print-While-Drive runs reported here.