Research Summary Report of A03

Extrusion of Near-Nozzle Mixed Concrete – Individually Graded in Density and in Rate of 3D Fibre Reinforcement

[1.12.2023]

Hechtl, Christian Maximilian, TP editor, m.hechtl@tum.de, TUM, cbm

Dr.-Ing. Kränkel, Thomas, PL, thomas.kraenkel@tum.de, TUM, cbm

Prof. Dr.-Ing. Gehlen, Christoph, PL,

gehlen@tum.de, TUM, cbm

The goal of A03 is to establish a concrete extrusion process using a near nozzle mixing (NNM) approach to enable the gradual variation of material properties during printing (gradation). This approach allows for the creation of multifunctional components, such as structures merging both load bearing and thermally insulating zones, by precisely altering material properties as required throughout the printing process.

Summary and Current State of Research

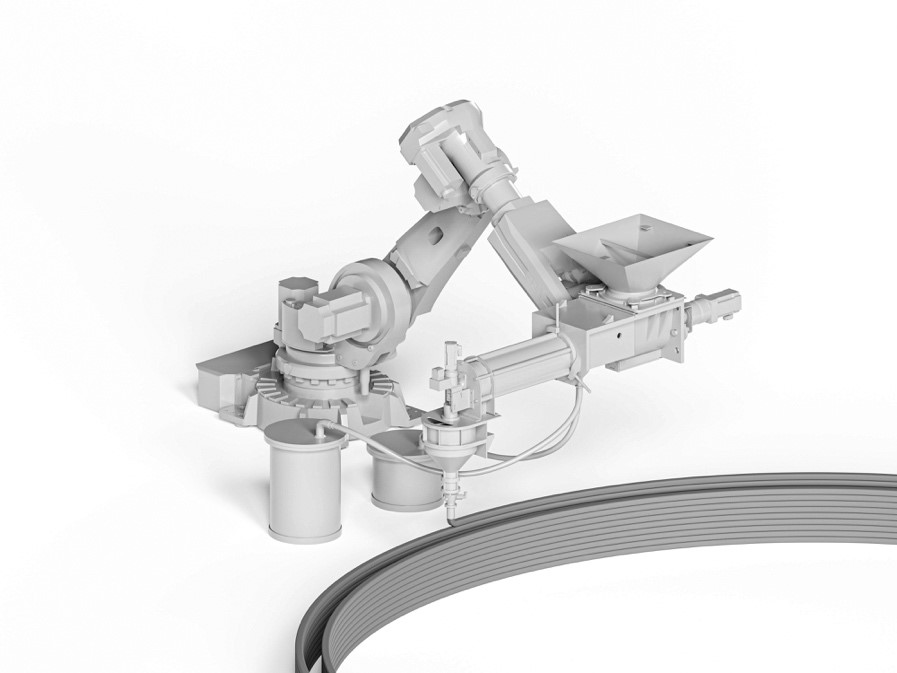

GRES V1 is a gradation-ready extrusion system that demonstrates the potential to extrude a homogenous mix of concrete with low variation in properties. However, the first prototype had some weaknesses that led to dead zones in the mixing chamber, material build-up, and clogging.

GRES V2 was developed to address these issues by redesigning both the process as well as the entire system. It consists of a shortened mixing compartment supplied with aggregates, cement paste, and water or additives as required. This new design allows the cement paste to be prepared in advance, improving the performance of the binder and reducing mixing time and energy consumption in the NNM System. The gradation of material is achieved by altering the type of aggregates and the binder to aggregate ratio. An additional water supply is provided in order to react to possible different water requirements of the various aggregates and to control the water to binder ratio during printing. Preliminary tests of GRES V2 show improved material homogeneity over the entire printing period and a well adjustable transition between different material properties.