Research Summary Report of C03

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

[18.11.2022]

Auer, Thomas; PL, thomas.auer@tum.de

Briels, David; doctoral researcher, david.briels@tum.de

Nouman, Ahmad; doctoral researcher, ahmad.nouman@tum.de

all: Technical University of Munich, TUM School of Engineering and Design, Chair of Building Technology and Climate Responsive Design

This research explores the potential of AM for building components with (a) directly incorporated active performative features (e.g. ventilation, thermal activation, or building services distribution), as well as (b) passive design strategies (e.g. thermal insulation, sound insulation, acoustics, or controlled solar gains) via material and geometric differentiation. The objectives are a more robust building operation, reducing embodied and operational carbon emissions, and improving user comfort, achieved by a more holistic, climate-aware, and fabrication-aware design, combining building physics with manufacturing-related constraints, as well as structural design. This is based on a parametric, simulation-based design approach.

Summary

The emphasis within this research is on developing, modelling, and testing individual building-physical functional integration targets. For example, optimizing the internal structures of wall elements based on heat transfer simulations, shifting thermal loads by integrating closed-loop air channels within an AM façade element, or implementing electrical heating wires for a fast-reacting decentralized heating system are some of the use cases. Furthermore, building service distribution (e.g., ventilation shafts, cabling, plumbing), thermal activation, acoustically enhanced material and geometry, and optimized wall joints for sound insulation are addressed.

So far, the scope has been limited to assessing individual functionalities at element level and developing small-scale prototypes for analysis and experimentation. Single functionalities are also tested and evaluated in larger-scale demonstrators.

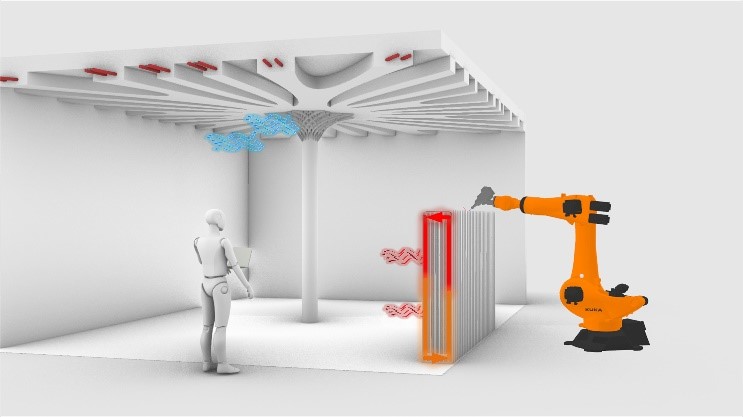

A series of performative features are selected to apply on AM building elements. Certain simulations and tests have been designed and performed to understand the effects of the integration of single functions on element-level and room-level. A few of the chosen components are the “multi-functional, mono-material, multi-layered AM murocaust façade (M3AM)”, a ribbed slab, a hollow-core column, and a cellular wall (see Fig 1).

Current state of research

The M3AM façade pivots on thermal load shifting technique for passive heating and cooling. It also benefits from the insulating potential of complex internal geometries. A set of coupling strategies for the air movement inside the M3AM cavities have been formulated and applied in thermal simulations, showing promising opportunities.

The ribbed slab has a positive effect on reducing dead load and wasted material. It can also increase thermal and acoustic comfort. This project investigates the influence of the increased heat transfer surface of thermally activated ribs by calculating the mean radiant temperature (MRT). By that different functionalities can be combined with this geometric differentiation.

The hollow-core columns also reduce the amount of needed material for building components. This project is targeting to reduce the use of piping material and fire dampers by directly integrating ventilation channels in hollow-core columns.

Room-level acoustic simulations are being performed to utilize the variety of texture and material characteristics that each printing technique offers. Various designs such as slabs, interior walls, and columns are included to understand their effects on the acoustic quality of the space.

Fig 1: Passive heating (M3AM façade), active heating (ribbed-slab), and ventilation (hollow-core column) through additive manufacturing – concept. / Credit: AMC – C03

Multiple active and passive component integrations via Additive Manufacturing in Construction

Visual Analysis – Room level acoustics with Additive Manufacturing components