Research Summary Report of A08

Structural Timber by Individual Layer Fabrication (ILF)

[14.10.2022]

Buschmann, Birger; Doctoral researcher, birger.buschmann@tum.de,

Talke, Daniel; Doctoral researcher, talke@tum.de

Henke, Klaudius; Project leader, henke@tum.de

Technical University of Munich, Chair of Timber Structures and Building Construction

The main goal of the project ‘A08 -Structural Timber by Individual Layer Fabrication (ILF)’ is to develop a process to additively manufacture large-scale, wood composite objects with a maximum content of wood material and strength values suited for applications in construction. In the course of the project multiple process variants and material combinations are explored. For this, the necessary machinery is developed in iterative steps and the mechanical properties of the resulting objects as well as the geometric capacity of the processes are investigated. Finally, multiple demonstrators are fabricated for showcase purposes.

Summary

Within A08 the working group Henke is researching the ILF method as a whole and developing a working process chain together with the necessary machinery.

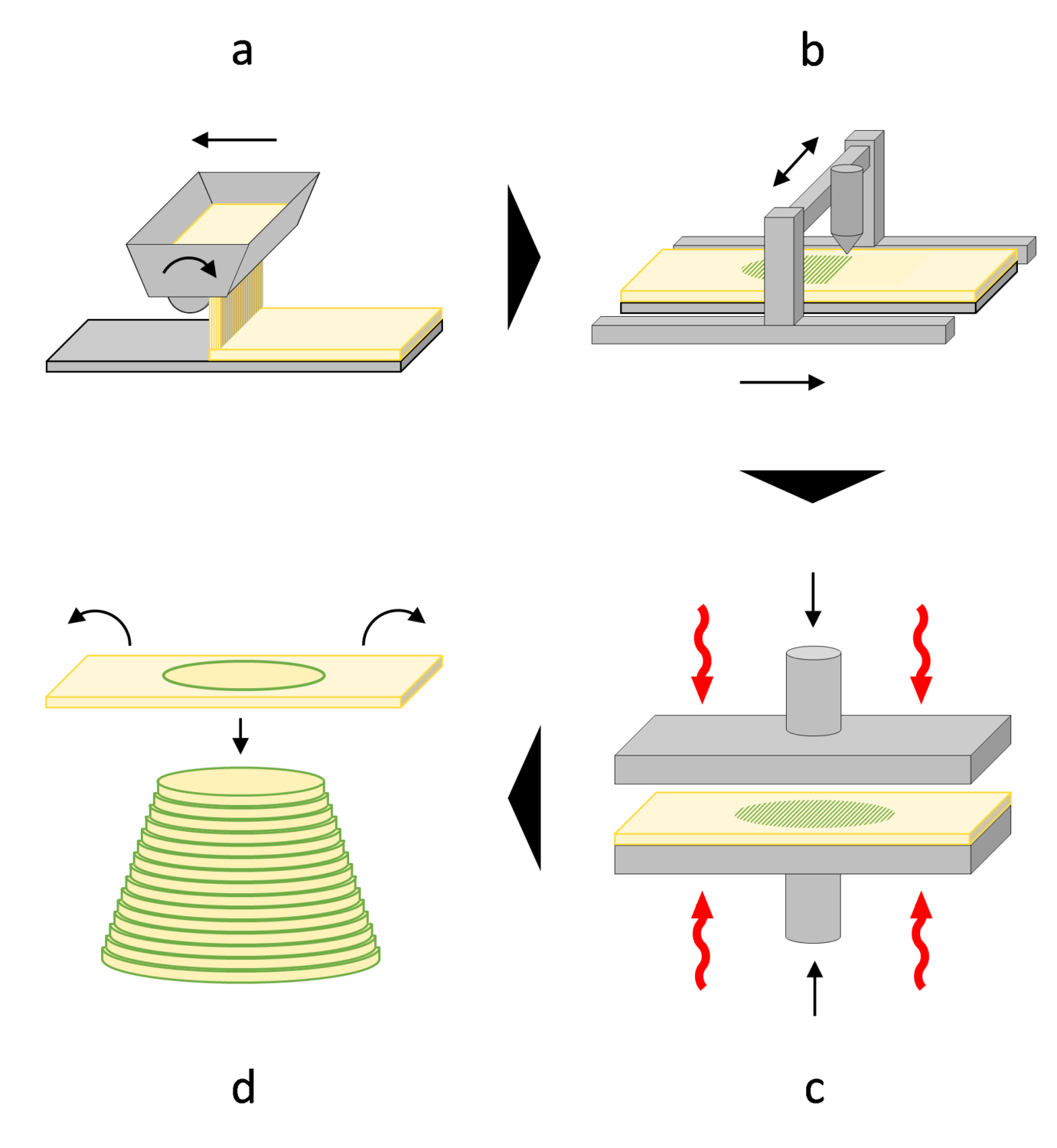

The general scheme of the ILF process is displayed in Figure 2 and can be divided into four main steps. A thin layer of wood particles is scattered (a) and bound by locally dispensing adhesive according to the target geometry of the object (b). After dispensing the adhesive, the wood particle layer is pressed (c). In doing so, the amount of required adhesive is drastically reduced while at the same time the mechanical properties of the wood composite are increased. Finally, the unbound material is removed and the contoured layer of bound material is laminated onto the stack of previously produced layers (d).

Current state of research

For each of these process steps the respective machinery is either developed or acquired and modified if necessary. With the manufacturing of various demonstrators (an example is shown in Figure 1) knowledge is gained about the intricacies of the ILF process and its practical applications. A suitable process parameter framework, geometric limitations and possible improvements are identified.