Research Summary Report of A03

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

[09.12.2022]

M.Sc. Dahlenburg, Maximilian; TP editor, maximilian.dahleburg@tum.de,

Prof. Dr.-Ing. Fottner, Johannes; Project leader, j.fottner@tum.de,

TUM, Chair of Materials Handling, Material Flow, Logistics

The main goal of A03 is to establish a novel concrete extrusion process using a near nozzle mixing (NNM) process to enable the change and non-discrete gradation of material and its properties during printing. With this approach multi-functional and multi-material parts can be printed, with an overall higher building rate due to a lower workability demand of the process and higher structuration rates of the used materials. Printed parts can thus simultaneously fulfill load-bearing and thermal insulation functions by locally changing the material properties. Thus, the sustainability of the printed parts can be improved through their intended use of material.

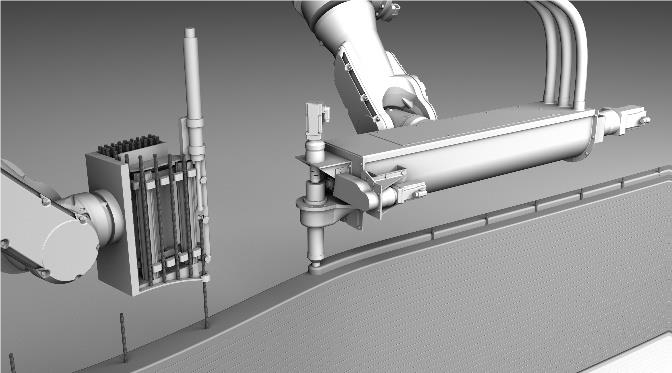

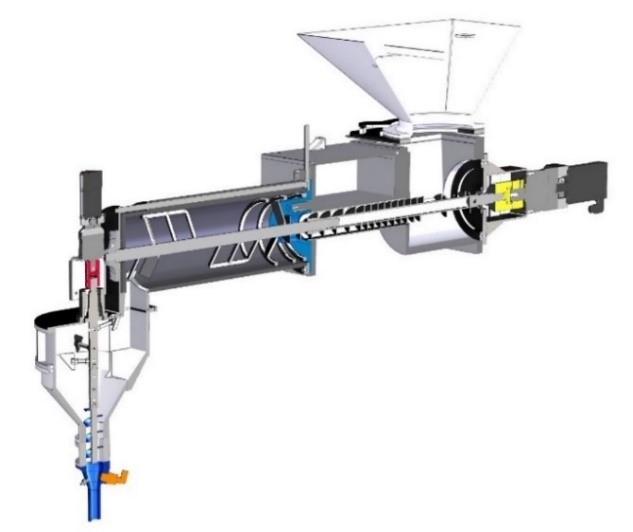

Gradation-ready-Extrusion-System (GRES) eliminates long pumping distances known from “conventional” extrusion systems, hence reducing the need of temporary flowability. By switching between different aggregates and with the precise dosing process of liquid phases GRES allows a robust change of material properties. Combining GRES with other AM processes elevates the potential of AM. This will be shown by producing a collaborative demonstrator together with C03 incorporating functions and C04 automating path generating according to the outside and inside wall geometry.

Current state of research

The development of GRES is progressing as planned. Meanwhile GRES v3 has been designed and manufactured and is currently being tested at the AMC Lab of TUM. With further automation, geometrical optimizations, function integration, and optimized controllability through the regular implementation of user experience data, the system is advancing towards a robust prototype with promising results.

Whereas previous versions of GRES (v1, v2) had issues with clogging inside the compression section, the current prototype reliably prints two different mortars (Lightweight mortar, Natural sand-based mortar). A redesign/optimization of the compression section enables short term (<4 min) material storage through a bigger reservoir, which now decouples the mixing- and compression section. This not only reduces the calibration process of new materials to a minimum but also allows to decouple material production and printing speed. Thus, optimal parameters for mixing can be determined without changing the output velocity, by switching material production on only when material is needed in the compression section. A possible downside is that storing material that is optimized towards buildability may cause the mortar to develop high yield strength inside the system. By implementing multiple agitators, optimized in angle and position inside the compression section (see figure 3), the material is not only kept in movement to counteract thixotropy effects but also actively pull-out material of the mixing chamber to avoid clogging. Furthermore, a material change sequence was

developed to change material.

In construction, proofing build quality is an underestimated task on which the construction industry invests a lot of time, and thus money, to ensure a safe building environment and high standards. Since GRES v3 continuously logs all relevant process data such as temperatures, pressure, velocities, etc., the user can monitor the process during or after the process.