Project C 02

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces

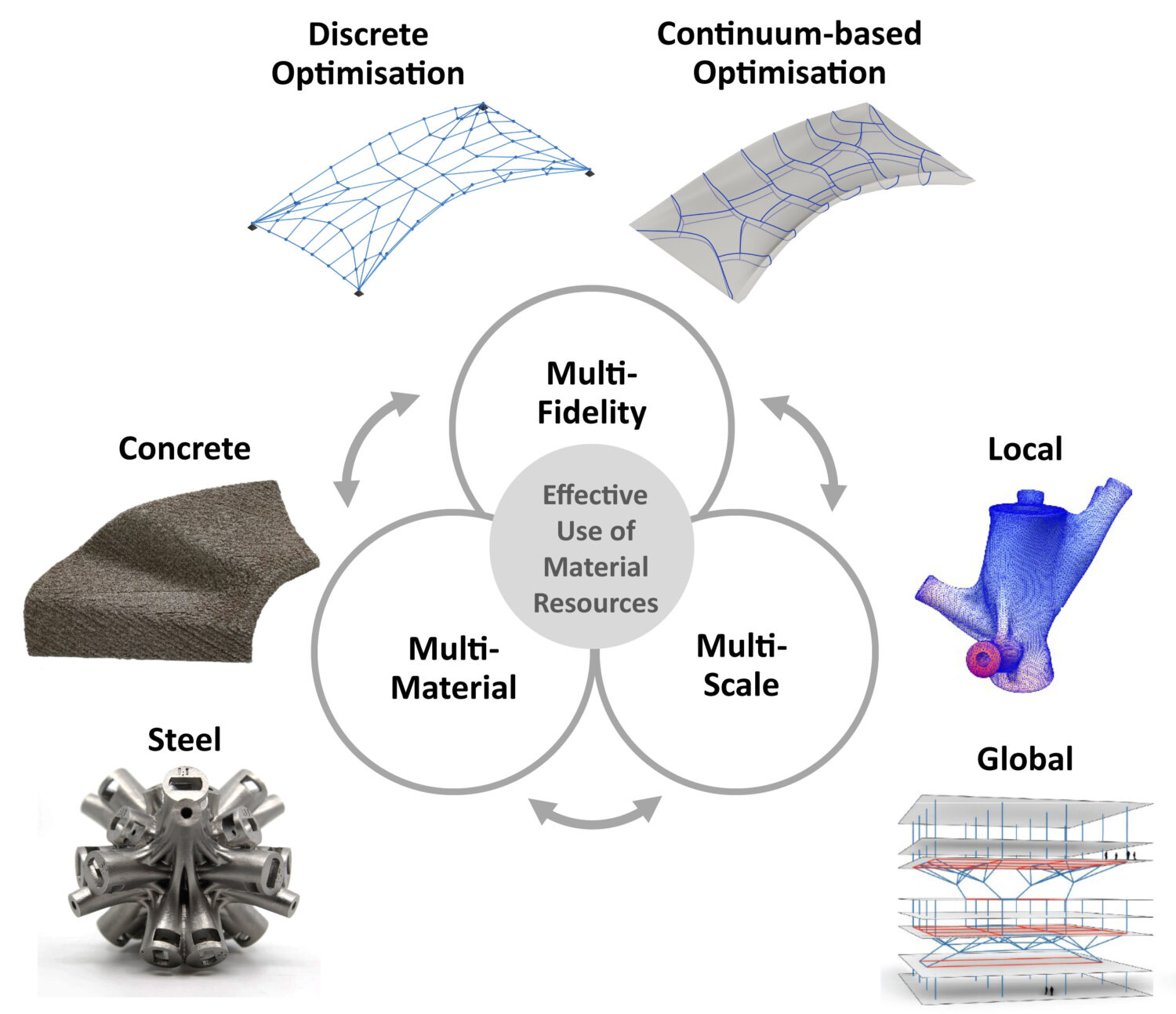

The CO2 Project addresses excessive material consumption in construction by developing a Holistic Design Framework (HDF) for Additive Manufacturing in Construction. Current building practices often treat architectural, structural, and fabrication aspects separately, leading to material inefficiency. To address this, the HDF integrates these aspects concurrently by combining two complementary strategies: a Discrete Optimization Approach (DOA) for low-fidelity structural exploration and a Continuum-Based Optimization Approach (COA) for high-fidelity structural refinement.

Objective

Formalization of a Holistic Design Framework (HDF) based on:

- Multi-fidelity: bi-directional coupling of Discrete Optimization Approach (DOA) and Continuum-based Optimization Approach (COA).

- Multi-scale: concurrent design of optimal structural forms (global scale) and segmentation into structural components (local scale).

- Multi-material: adaptability to different material models and opportunity for material grading.

- Integration of specific AM-process-related constraints and objectives.

- Development of dedicated interfaces to other AEC disciplines (building physics, building informatics, construction management, life-cycle

Approach

The proposed framework will lead to material savings by designing efficient structural forms that can be realized through additive manufacturing. These structures will fulfil requirements and objectives according to the respective design task by iterating the

following workflow:

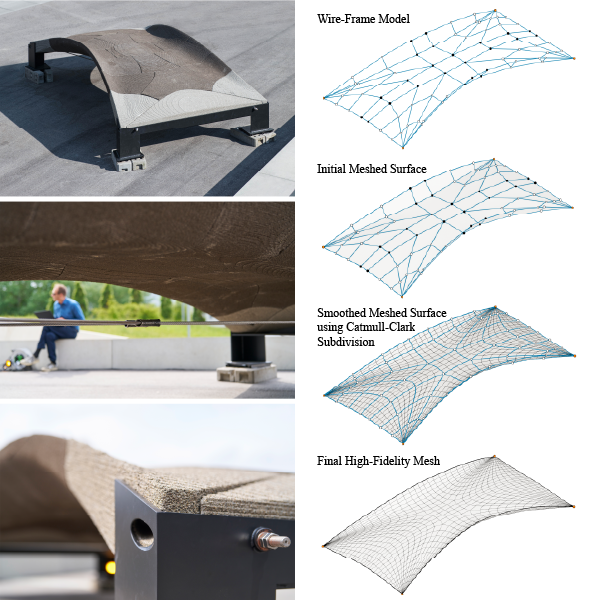

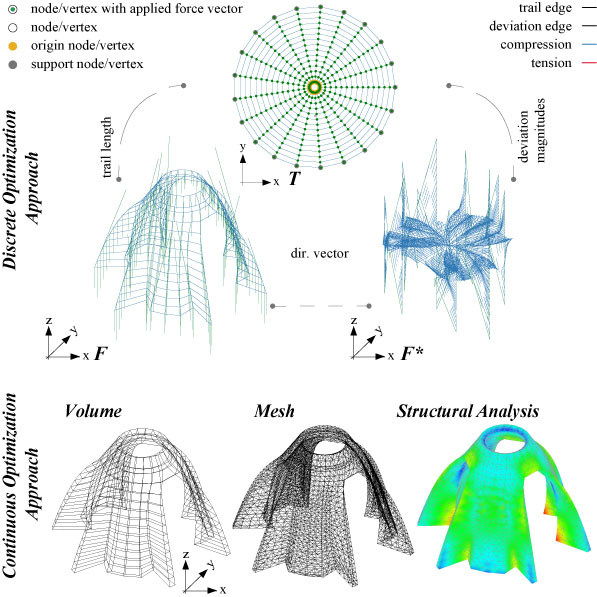

a. Exploration of the design space by form-finding structural forms in static equilibrium as discrete strut-and-tie networks (low-fidelity) using a Discrete Optimization Approach (DOA); generated structures

are optimized for additive manufacturing constraints and objectives based on topological and geometric design parameters.

b. Conversion of selected design solutions into continuous solid geometries with an associated material model for detailed design iterations (high-fidelity); topological, shape, and material optimization are carried out using a Continuum-based Optimization Approach (COA).

c. Back-mapping from COA to DOA for incorporating further insights gained by high-fidelity model optimization into the fast global design space explorations.

d. Segmentation of the optimal structural form (global scale) into components (local scale).

e. Integration of additional constraints and objectives derived from other disciplines, such as building physics and sustainable design.

Networking with other projects

Structural design plays a key role in additive manufacturing, both at the scale of entire structures and their individual components. Our methods are tailored to the specific requirements of various AM techniques, including particle-bed processes (e.g., SCA, SPI, SLM) and extrusion-based methods (e.g., WAAM, I3DCP). Close collaboration, especially with several A projects (e.g., A01, A09, A10) ensures these methods account for fabrication constraints. Additionally, we work with projects in focus area C to extend our framework toward integrated, multi-objective optimization—linking structural performance with building physics and sustainability (e.g., via C03). The Holistic Design Framework (HDF) developed in this project serves as a shared platform for testing and real-scale implementation across TRR 277.