Project A 03

Networking with other projects

Poster

TRR277_A03_230601_TP_Poster_FP1TRR277_A03_230601_TP_Poster_FP2

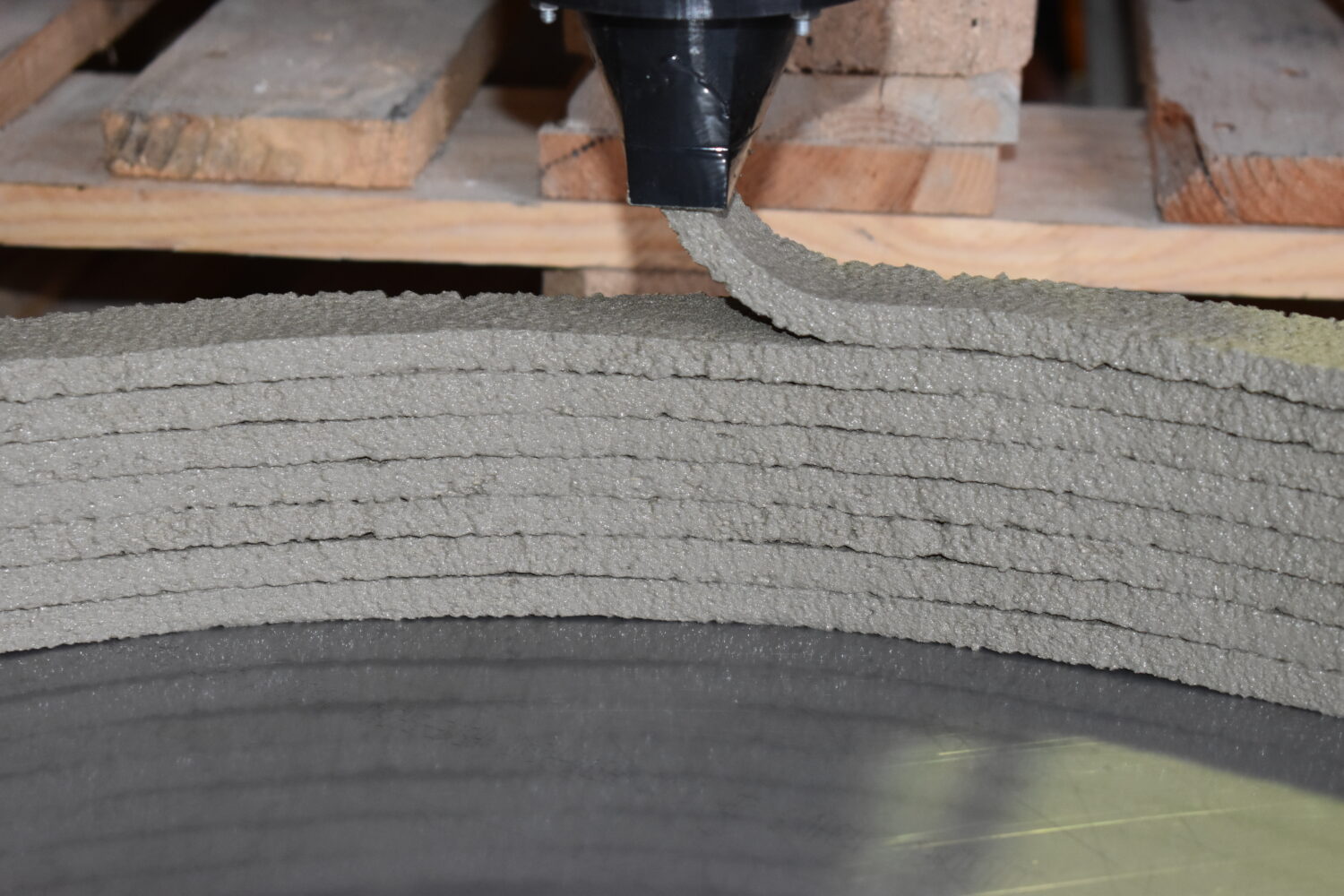

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

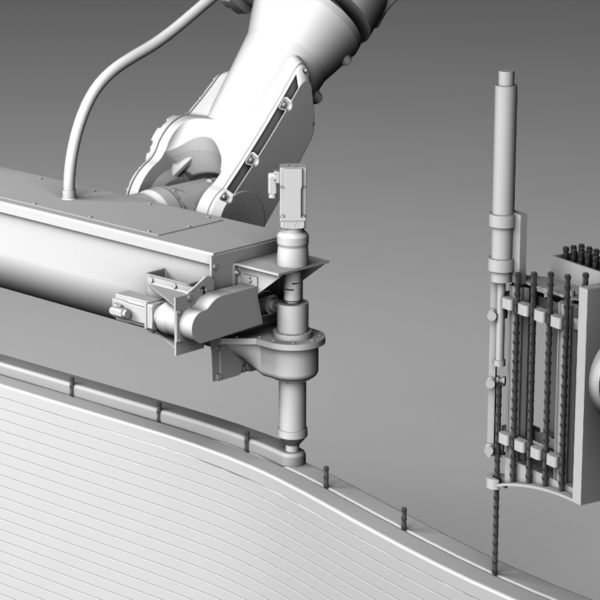

The gradation of material properties in concrete extrusion allows more efficient use of resources and multifunctional design of components, but represents a particular challenge in pump-based extrusion systems. Therefore, an innovative near-nozzle mixing system, called gradation ready extruding system (GRES), is being developed in A03 which enables immediate gradation of the material properties. This allows to locally extrude different materials ranging from normal to lightweight concrete. Furthermore, the short conveying distances for the fresh concrete facilitate the extrusion of e.g. more sustainable materials that cannot be processed in previous extrusion systems due to impeded workability compared to normal 3D printing materials. The combination of multi-material printing with an automated vertical rebar insertion strives for high performance as well as a precise adjustment of material properties to the local needs and thus for a more sustainable material use.

Aim

Graded Concrete Extrusion

- Design and construction of a gradation ready near-nozzle mixing system and its implementation on an industrial robot

- Development of discrete material gradation (with regard to thermal conductivity, strength, and sustainability)

- Integration of an automated vertical layer reinforcement

- Conception and production of a multi-material construction element

Approach

Experimental investigation and DEM-Simulation

- DEM Simulation for system function validation

- Experiment based development and optimization of process and materials for gradation

- Quantification and validation of material properties for graded concrete extrusion

Networking with other projects

- A02: Construction of a demonstrator combining the technologies

- A04: Collaboration on vertically inserted reinforcement using the same insertion device

- A05: Evaluation of suitable reinforcement strategies

- A08: Construction of a demonstrator combining the technologies

- B04: Collaboration on path planning as well as process and control parameters. Furthermore, collaboration on adaption of insertion device (together with A04)

- B05: Collaboration on extrusion of (lightweight) concrete, e.g. with regard to material development and supply, as well as on robot control

- C01: Thermal and geometrical optimization of a lightweight/graded concrete construction element

- C02: Collaboration on optimization of graded concrete elements; input for simulations

- C03: Thermal and geometrical optimization of a lightweight/graded concrete construction element

- C04: Input for BIM

- C05: Collaboration on dry joints and conception of joints between different AM technologies

- C06: Discussion on pre-fabrication and in-situ manufacturing

- C07: Exchange on requirements for standardization processes