Research Summary Report A03

Extrusion of Near-Nozzle Mixed Concrete – Individually Graded in Density and in Rate of 3D Fibre Reinforcement

[15.04.2022]

Dahlenburg, Maximilian; Researcher

Fottner, Johannes; Project Leader

all: TUM, Chair of Materials Handling, Material Flow, Logistics

A03 has the main goal to make graded concrete extrusion possible. Therefor an innovative near-nozzle-mixing system is being developed, optimized, and tested.

Summary

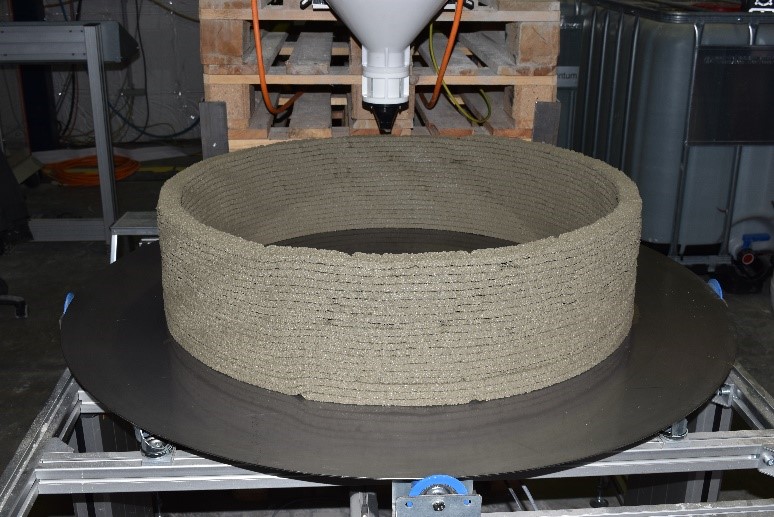

The evolution of 3D-concrete printing is advancing at a fast pace worldwide due to the great potential of these technologies regarding time-, resource efficiency and sustainability. This project focuses on enabling graded concrete extrusion by manipulating material properties in-situ. Furthermore, it targets to handle general additive manufacturing (AM) problems with concrete regarding limitations in the material design. In state-of-the-art concrete printers material is premixed and then conveyed in long hoses from pump to nozzle. The result is a dilemma in Material design having two opposing material properties: workability vs. flowability. Therefore, the gradation ready extrusion system (GRES) is being tested and optimized at the Chair of Materials Handling, Material Flow, Logistics at TUM (see Fig. 1).

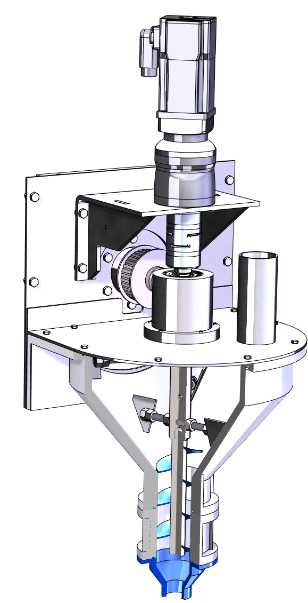

This system eliminates long pumping distances and thus highly reduce the need of temporary flowability by mixing the material near nozzle. By changing between different dry compounds and the precise dosing of liquid and solid phases GRES allows the manufacturing of graded elements, with locally differing material properties. By supplementing this technology with those of other Projects in the TRR comes great potential for AM in construction. Combining GRES with other AM processes elevates the potential of AM significantly.

Current state of research

During intensive testing, optimizing potentials of GRES have been identified to improve the system, to be robust and reliable. Therefore, all zones without material movement (dead zones) have been flagged and are being iteratively removed by adding plastic 3D printed dead zone blockers. Furthermore, a new compression section has been designed to smoothen layer deposition, eliminate dead zones, and enhance print quality (see Fig. 2).

This newly designed section consists of multiple adjustable angled paddles that prevent material to build up inside the compression compartment. To prevent material buildup in the previous conveying section, the top paddles of the compression screw reach into the conveying section to actively extract material. In the sense of basic research, the screw and its housing are exchangeable to optimize the deposition quality via optimized screw geometry.

After analyzing the precision of the volumetric dosing unit, and foreseeing problems concerning consistent material quality by unprecise dosing of the solid, dry materials this system is being substituted. Therefor a gravimetric dosing unit is currently being tested to reach the required metering accuracy of < 1.5%.

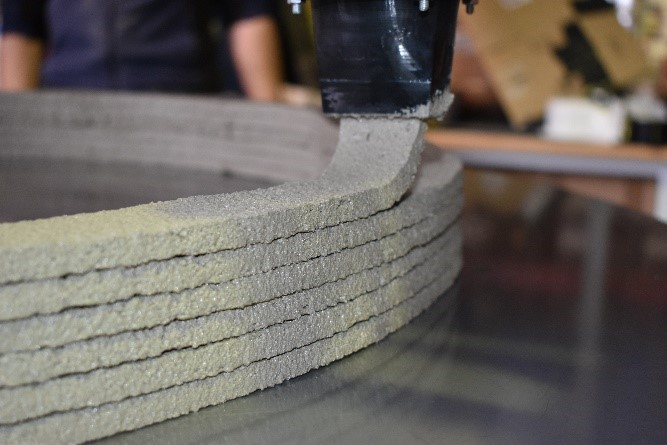

With ongoing tests together with working group Gehlen (A03-1) at the AMC Lab in Freising we are actively validating abovementioned optimizations as solutions for the upcoming second prototype (see Fig. 3). This second iteration will be focusing not only on enhancing reliability and automation but also on lightweight construction and compatibility with a portal system to print larger scale elements than possible with the current industrial robot.

Fig 1: Column printed with compression section V2/ Credit: M. Dahlenburg, M. Hechtl, B. Saile

Fig 2: Compression section V2 responsible for compaction, mounted to the front of GRES / Credit: M. Dahlenburg

Fig 3: Printing of a cylindrical column with GRES / Credit: M. Dahlenburg, M. Hechtl, B. Saile