Project B 04

Networking with other projects

Poster

TRR277_B04_Poster_1-DFG-Begutachtung

TRR277_B04_Poster_2-DFG-Begutachtung

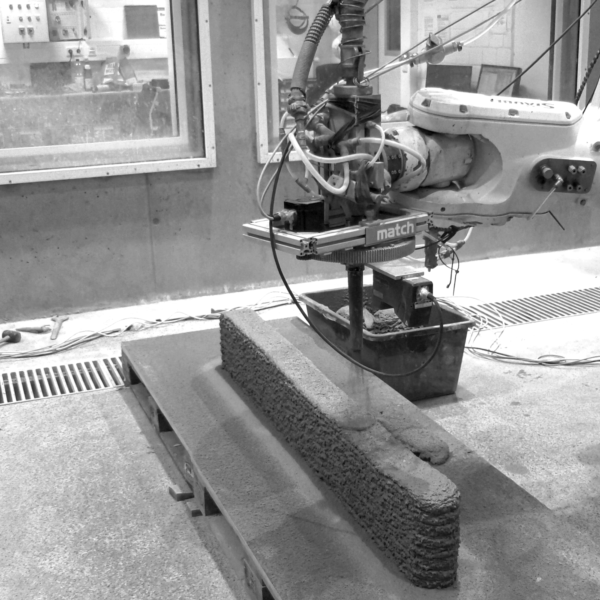

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom

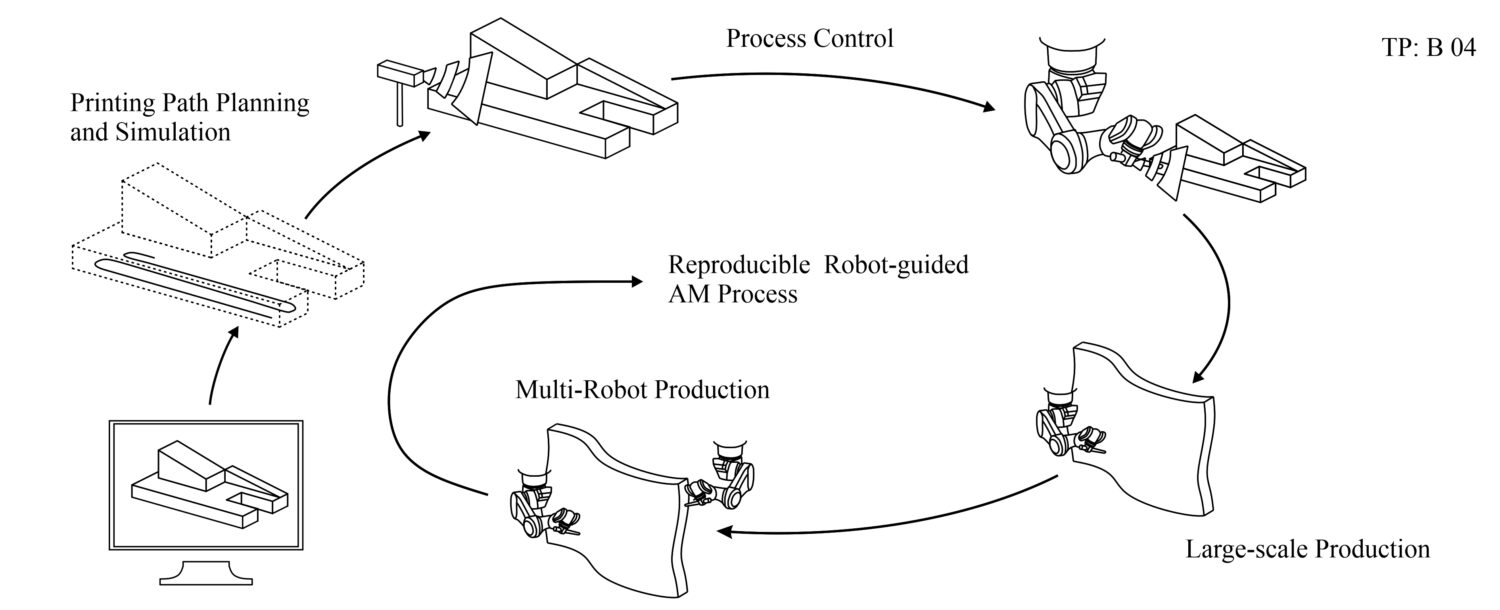

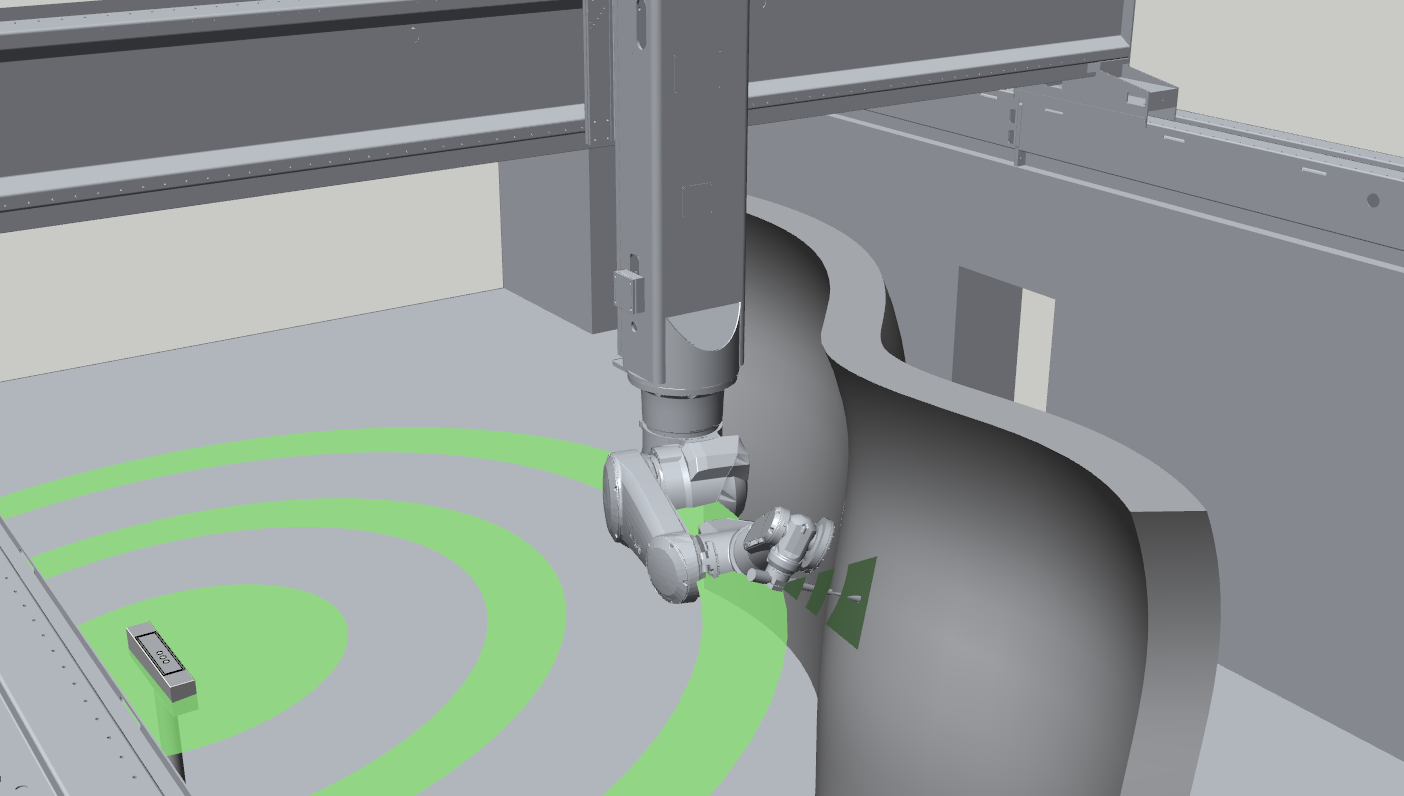

The integration of robot-guided Additive Manufacturing in construction will foster the degree of automation and can thus lead to increased productivity and improved component quality. In this project, a multi-criterion path planning is developed, based on an application process model that includes geometrical data and time-dependent physical material properties. Together with multimodal systems, a sensor-guided control for an adaptive online path planning will be implemented. Further, multimodal sensors and new control strategies are investigated to control cognitive and cooperative autonomous robot units with an extended degree of freedom.

Aim

The aim of this research project is to develop a reproducible robot-guided additive manufacturing process based on multi model adaptive path planning and process control for the production of high-quality, large and complex concrete components.

Approach

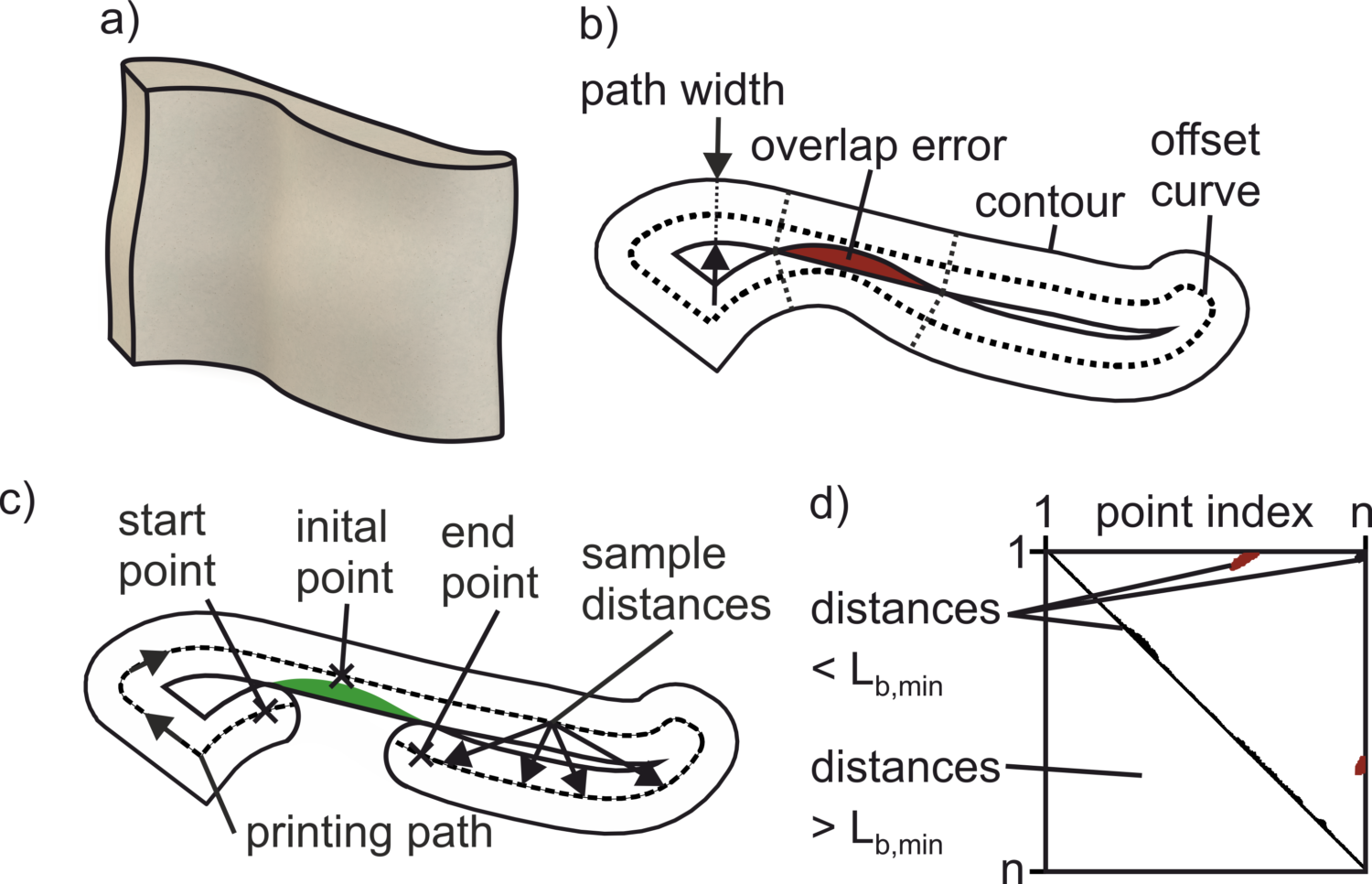

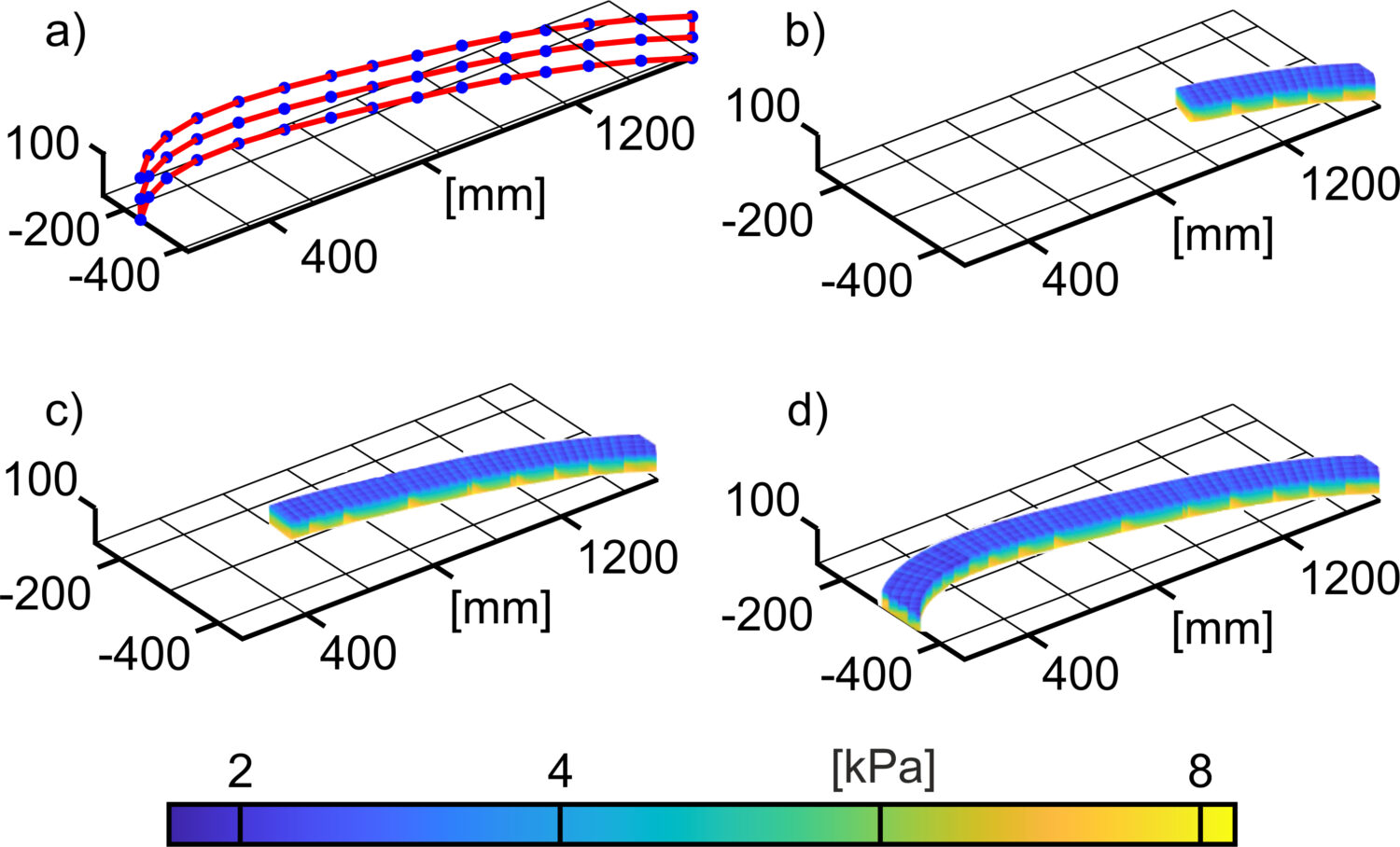

Based on physical modelling of the material behaviour, the numerical analysis of the printing process with respect to varying process conditions allows for a priori printing stability evaluation. Based on the simulated deformations, printing path optimization becomes possible and results in ensured component stability throughout the component production. In combination with advanced online control strategies and a sensing production system, large components will be realized utilizing the SC3DP process.

Networking with other projects

This project researches the modelling, monitoring, control and path planning of shotcrete application with industrial robots for the TRR 277. Thereby, B04 also serves as the first point of contract for quastions concerning all matters of robot control for all other projects.