Project A 02

Networking with other projects

Poster

TRR277_A02_Poster_1-DFG-Begutachtung

TRR277_A02_Poster_2-DFG-Begutachtung

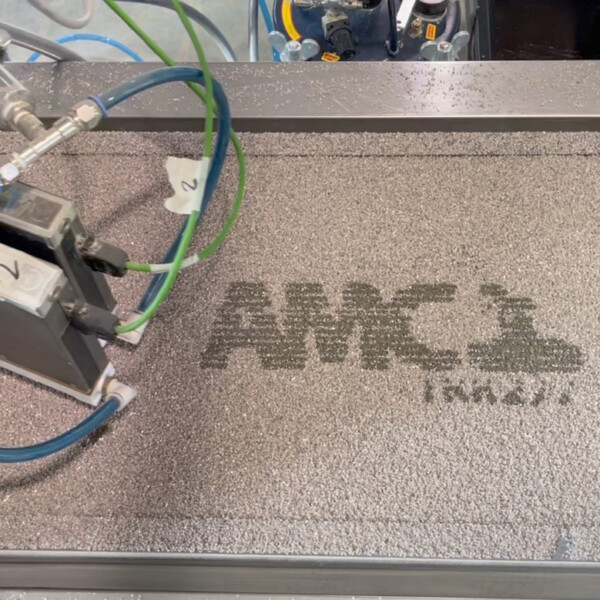

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

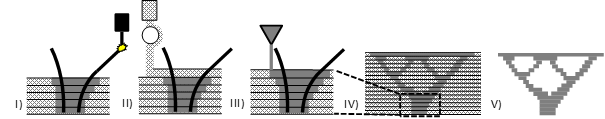

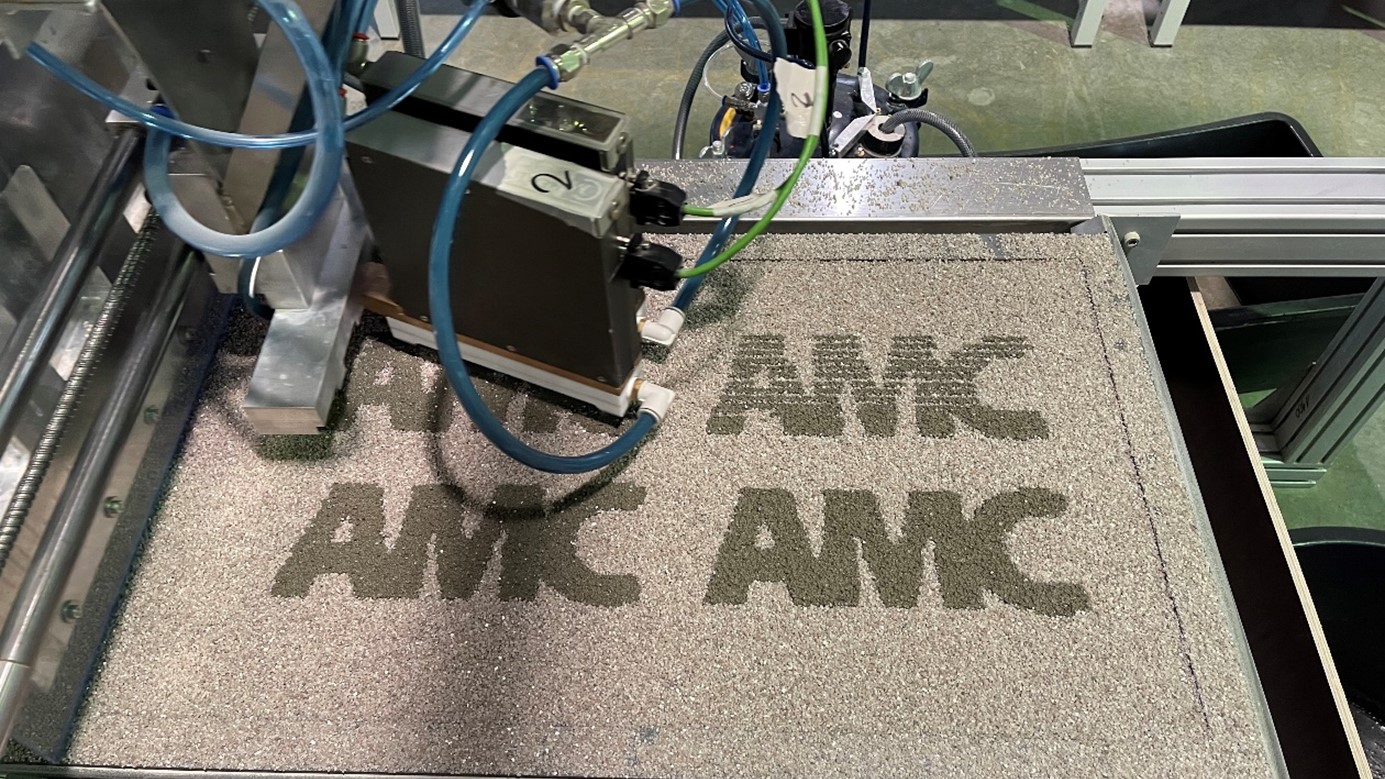

Selective paste intrusion (SPI) is a particle-bed-based additive manufacturing technology in which aggregates are spread in thin layers and bonded by cement paste. To qualify SPI for structural concrete elements, the inclusion of reinforcement is mandatory. The innovation introduced here is that reinforcement will be implemented simultaneously in the SPI process using Wire and Arc Additive Manufacturing (WAAM). Different active and passive cooling strategies, e.g. particle surface functionalization and the synthesis of new particles, will be developed to deal with the high temperatures during WAAM.

Objective

Combination of SPI and WAAM:

- 3D printable WAAM reinforcement with properties comparable to those of conventional rebars, validated through experiments and simulation

- Development of tailored particles for cooling and storing water for the combined SPI+WAAM process

- Optimized cement paste for enhanced temperatures

Approach

At the cbm, the Selective Paste Intrusion (SPI) is being researched. One research focus is the integration of reinforcement using Wire and Arc Additive Manufacturing (WAAM) during the printing process. Due to the temperature loads of the WAAM process, the system limits, such as the maximum temperature load in the SPI process, must first be quantified. From this, process parameters and strategies to reduce the temperatures are derived and also researched. Approaches here are the functionalization of the aggregates and optimization of the cement paste formulation to withstand higher temperatures. However, an increase in the distance between the particle-bed and the printer nozzles and active cooling of the WAAM process are strategies for reducing the temperature load. The aim is to combine the two individual processes, SPI and WAAM, into one process and produce a demonstrator.

The Institute for Particle Technology is conducting a closer inspection into developing tailored particles suitable for the hybrid process. On the one hand, an optimal combination of particle size distribution and morphology of the aggregate particles as well as cement paste are to be found to support the process. On the other hand, the effect of certain additives on both components are being studied to reduce or withstand the remaining thermal load. One approach involves integrating additional water into the aggregate bulk material and cement paste whilst maintaining sufficient material properties for SPI. Further studies will involve combining the aforementioned with binding accelerators to increase process speed.

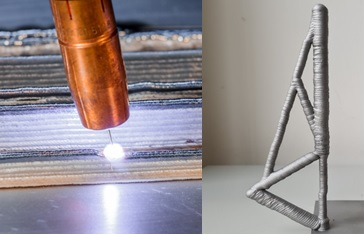

At the iwb, suitable process parameters for the production of WAAM-manufactured reinforcement structures are identified and process investigations are conducted with an experimental setup. Thereby, the cooling behaviour of the manufactured reinforcement geometries is analysed using thermographic imaging. Based on this, the cause-effect relationships in WAAM of the steel reinforcement are quantified by regression analyses. Numerical process models are created to extend the understanding of the process. These models describe the temperature distribution in the WAAM-manufactured component and consider the influences of specifically cooled areas. Thus, a suitable cooling strategy can be derived theoretically and be validated, after integration into the experimental set-up.

Networking with other projects

- A01: Permanent exchange of the project status within the workgroup

- A03: Permanent exchange of the project status within the workgroup

- A04: Joint series of experiments for the investigation of temperature influences

- A05: Integration of reinforcement in the SPI process

- A07: Exchange of process and material parameters of the WAAM reinforcement

- A08: Exchange about nozzle technology and printer automation (pin roller)

- C01: Sending of material properties for model calibration

- C02: Sending of material properties for model calibration

- C04: Exchange of process parameters for BIM

- C06: Sending of an SPI printed test object for 3D-laser scanning test measurements