Research Summary Report of C09

Environmental Life Cycle Assessment – Determination of Ecological Sustainability Potentials by AMC

[07.11.2025]

Albrecht, Sophie Viktoria; Researcher, sophie.albrecht@oth-regensburg.de

Thiel, Charlotte; Project leader, charlotte.thiel@oth-regensburg.de

OTH Regensburg, Construction Materials

Main Goal

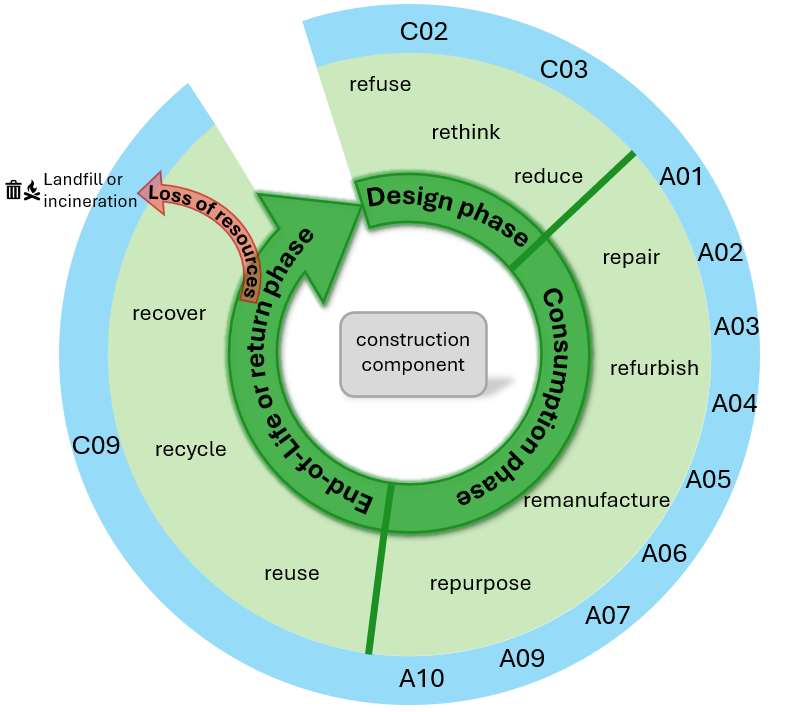

C09 aims to enhance the ecological sustainability of Additive Manufacturing in Construction (AMC) by quantifying and optimizing its environmental benefits through comprehensive Life Cycle Assessments (E-LCA) from cradle to cradle. This involves developing transparent Product Environmental Footprint Category Rules (PEFCR), identifying impactful reduction measures, and integrating circular design strategies to create durable, efficient, and reusable components. C09 enables early-stage, sustainability-focused decision-making, fostering material-efficient, low-impact construction practices and reducing the environmental footprint of the building sector.

Summary

The construction industry is one of the largest contributors to global environmental burdens, accounting for significant greenhouse gas emissions, resource consumption, and waste generation. To assess and mitigate these impacts, C09 conducts comprehensive Life Cycle Assessments (LCAs) of various Additive Manufacturing in Construction (AMC) processes in close cooperation with the A- and selected C-projects. These assessments identify the primary environmental hotspots within AMC workflows, and potential strategies to reduce these impacts are systematically researched and evaluated.

Circular economy principles are integrated into the design of construction components, and their influence on overall environmental performance is analysed. The project also investigates the suitability of different additive manufacturing processes for specific construction components, ensuring both functional performance and sustainability. Through the optimisation of materials, processes, and design strategies, Project C09 seeks to substantially lower the environmental footprint of the construction sector while advancing sustainable, circular, and resource-efficient building practices.

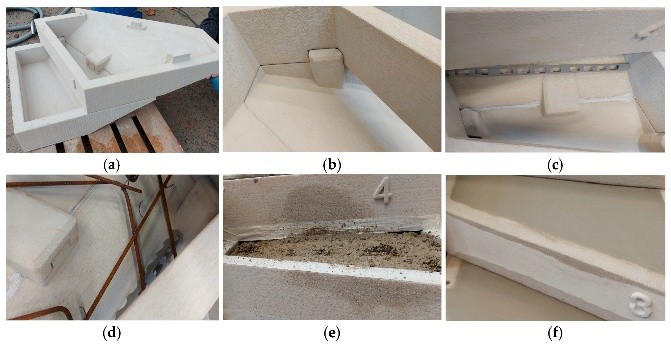

A concrete example of these efforts is a 3D printed lost formwork for a winding staircase. The study demonstrates the potential if additive manufacturing to improve material efficiency, and reduce waste, highlighting the importance of ongoing research into sustainable materials and process optimisation. By minimising resource use and promoting circularity, this example directly supports the LCA and circular economy objectives of C09

In collaboration within projects A04 – A07, the potential environmental impacts of various additive manufacturing processes and material systems are evaluated. Studies on basalt, glass, carbon fibres, and steel reinforcement, as well as steel K-node production, reveal key environmental hotspots and inform strategies for impact reduction. Further investigations address data limitations related to feedstock materials and aim to enhance the accuracy of LCAs through industry collaboration. In project A04, new shotcrete mixtures demonstrate the potential for lower global warming potential compared to conventional formulations.

Together with projects C02 and C03 we explore the design of a multifunctional, circular ceiling element that integrates optimized acoustic performance while maintaining structural and ecological efficiency.

Collectively, these efforts contribute to a deeper understanding of the environmental implications of additive manufacturing in construction and support the development of sustainable, circular, and resource-efficient building solutions.