Research Summary Report of C06

Integration of Additive Manufacturing into a Cyber-Physical Construction System

[16.04.2024]

Placzek, Gerrit; Doctoral researcher,

g.placzek@tu-braunschweig.de,

Schwerdtner, Patrick; Project Leader,

patrick.schwerdtner@tu-braunschweig.de

both: TU Braunschweig, IBB

Main Goal

The integration of additive manufacturing into construction requires an interdisciplinary approach. The different competences of the team – digital fabrication in architecture (Hack), geodesy and photogrammetry (Gerke) and construction management (Schwerdtner) – lead to research from diverse perspectives on the various scalar levels of construction to be viewed holistically: component, building and industry scale.

Within Subproject C06, the goal of the first phase was to create a continuous digital and lean-based process chain from design (using BIM method) to fabrication (using AM method). Based on process models und strategic decisions, we investigated how to change them into a construction industry 4.0 and will continue our research in this field in the second phase.

Summary

Since we classified four different robotic systems for extrusion-based in-situ additive manufacturing with concrete in our previous works, the technological diversity of concrete 3D printers is continuously evolving. ICON, a US Company and one of the AM market leaders, recently announced and presented their new concrete 3D Printing system, called Phoenix, that operates in a similar way to Constructions-3Ds Maxi Printer. As pointed out in previous Research Summary Reports and our publications, considering production planning, the selection of a suitable AR system is crucial for project success.

From a contractor’s perspective, it is important to determine at an early stage which situations call for specific types of 3D printers and which printer technologies are worth investing in. The main performance properties to be compared are – besides the general suitability and flexibility of the equipment – the time and labour required for transport, assembly (including calibration) and disassembly, as well as the printing speed. The data analysed show that for smaller build volumes the use of mobile systems may be more appropriate than large scale frame-based or gantry systems. However, there are still challenges in establishing general and comparative parameters since practical data are often missing or not shared to the public.

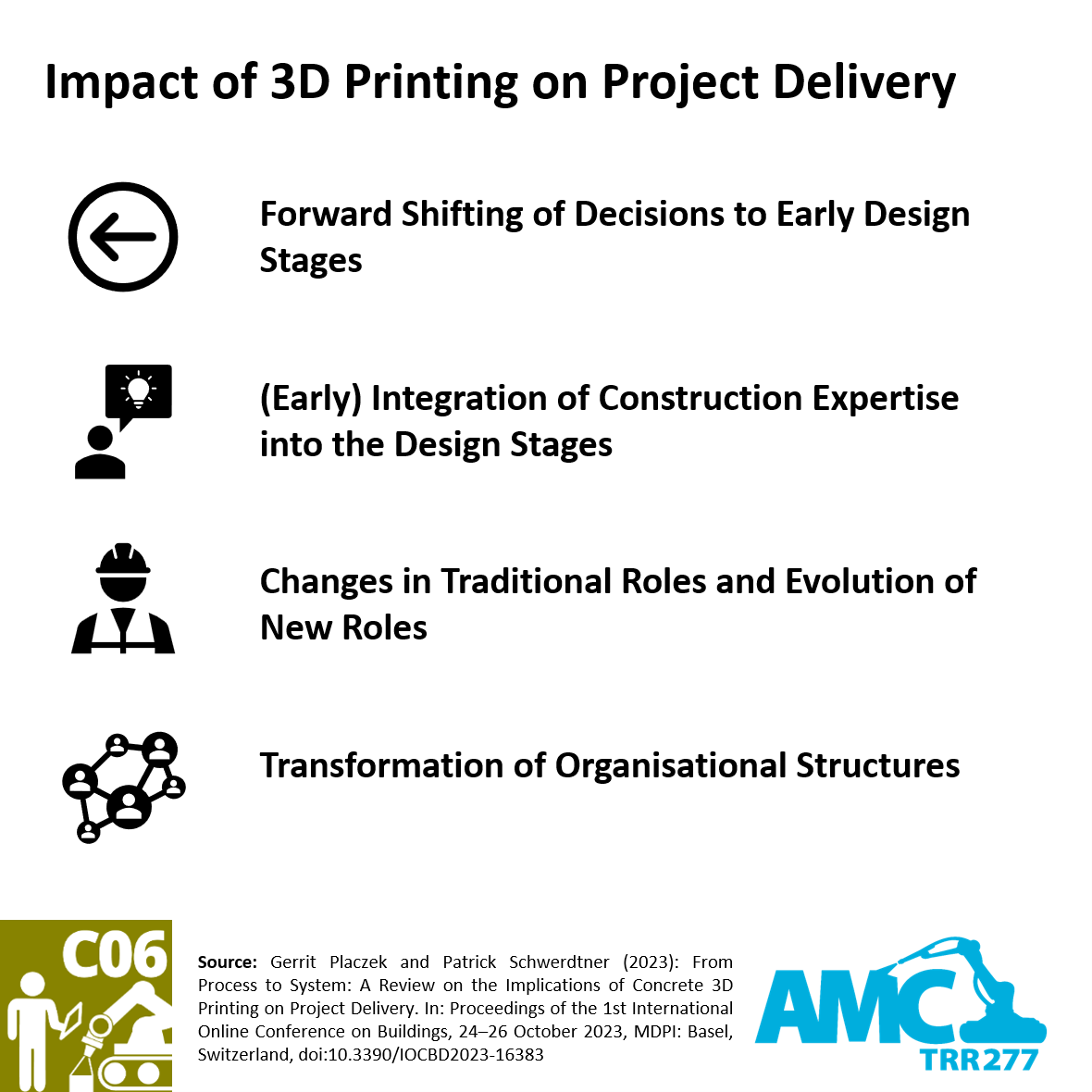

Investigating finished projects of 3D printing buildings will help to understand the need for alternative projects deliveries to foster the integration of additive manufacturing in the construction industry. So far, based on a literature review [2], the traditional planning and construction process will have to change. While on the one hand, new roles and changes in the responsibilities will emerge in the long term, on the other hand, a holistic design and construction process with early contractor involvement is needed on the short term.