Research Summary Report of C03

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

[29.05.2024]

Auer, Thomas; PL, thomas.auer@tum.de *

Briels, David; doctoral researcher, david.briels@tum.de *

Nouman, Ahmad; doctoral researcher, ahmad.nouman@tum.de *

* Technical University of Munich, TUM School of Engineering and Design, Chair of Building Technology and Climate Responsive Design

In engineering advancements, Additive Manufacturing in Construction (AMC) represents a significant paradigm shift. To fully harness the capabilities of AMC, our project, C03, is dedicated to fundamentally transforming the design of building elements. Additive Manufacturing (AM) facilitates the creation of highly specialized components that enhance both passive and active functionalities within buildings. It includes aspects of building physics, such as heat transfer and acoustics, and building services, such as heating, cooling, and ventilation. Our primary objective is establishing a robust building operational framework to significantly reduce embodied and operational carbon emissions. We also emphasize elevating indoor environmental quality, including acoustic and thermal comfort. We employ a climate-responsive and human-centric design strategy to achieve these goals. This approach utilizes parametric, performance-driven, and simulation-based methodologies to innovate in developing AM elements that seamlessly integrate and enhance passive and active functions.

Summary

This research investigates the potential of Additive Manufacturing (AM) to produce advanced building components that integrate and hybridize both passive and active functions, enhancing heat transfer, acoustics, moisture control, and building services like heating, cooling, and ventilation. AM’s ability to create complex geometries can optimize building physics and performance, potentially reducing reliance on traditional mechanical systems, decreasing carbon emissions, and improving indoor environmental quality (IEQ) and thermal comfort.

The study aims to develop a climate-responsive, fabrication-aware design by integrating building physics, services, and manufacturing constraints through parametric, performance-driven, simulation-based design methods and multi-objective, multidisciplinary optimization. AM’s unique capability to produce geometrically and materially differentiated components allows for integrating and hybridizing multiple performance features.

The primary research question is how AM technologies can directly incorporate active performance features (ventilation, thermal activation, building service distribution) and passive design strategies (thermal resistance, sound insulation, acoustics, solar gain control) through material and geometric differentiation—the initial funding period focused on developing, modeling, and testing individual functional integration targets, particularly in thermal performance, comfort, and energy efficiency. Efforts included optimizing wall elements’ internal structures, integrating air channels in façades, and implementing electrical heating wires. In this period, we also explored integrating building service distribution, thermal activation, and acoustics. Small-scale prototypes were developed for analysis and evaluation, and individual functions are being tested in large-scale demonstrators.

The objectives of the current funding period are to integrate, assess, and hybridize multiple functionalities simultaneously and translate these capabilities into practical design strategies for components and entire buildings, which requires scaling up simulations, prototypes, and demonstrators to room level, aiming for 1:1 large-scale, multi-functional demonstrators to evaluate manufacturing feasibility and validate models and simulations. The study aims for AM-enabled functional integration to enhance and simplify building design, construction, and operation.

Current state of research

TOVA – IAAC

C03 is conducting experiments at TOVA, Spain’s first 3D-printed earth building (Figure 1), as part of a collaboration with IAAC (Institute for advanced architecture of Catalonia). His work includes monitoring of indoor and outdoor environmental conditions to evaluate the building´s concept with regard to natural ventilation, shading, thermal mass, and hygroscopicity. He is also investigating passive cavity ventilation by measuring surface and air temperatures and air velocities within the building’s external wall cavities to assess thermal buoyancy.

BloXMurocaust

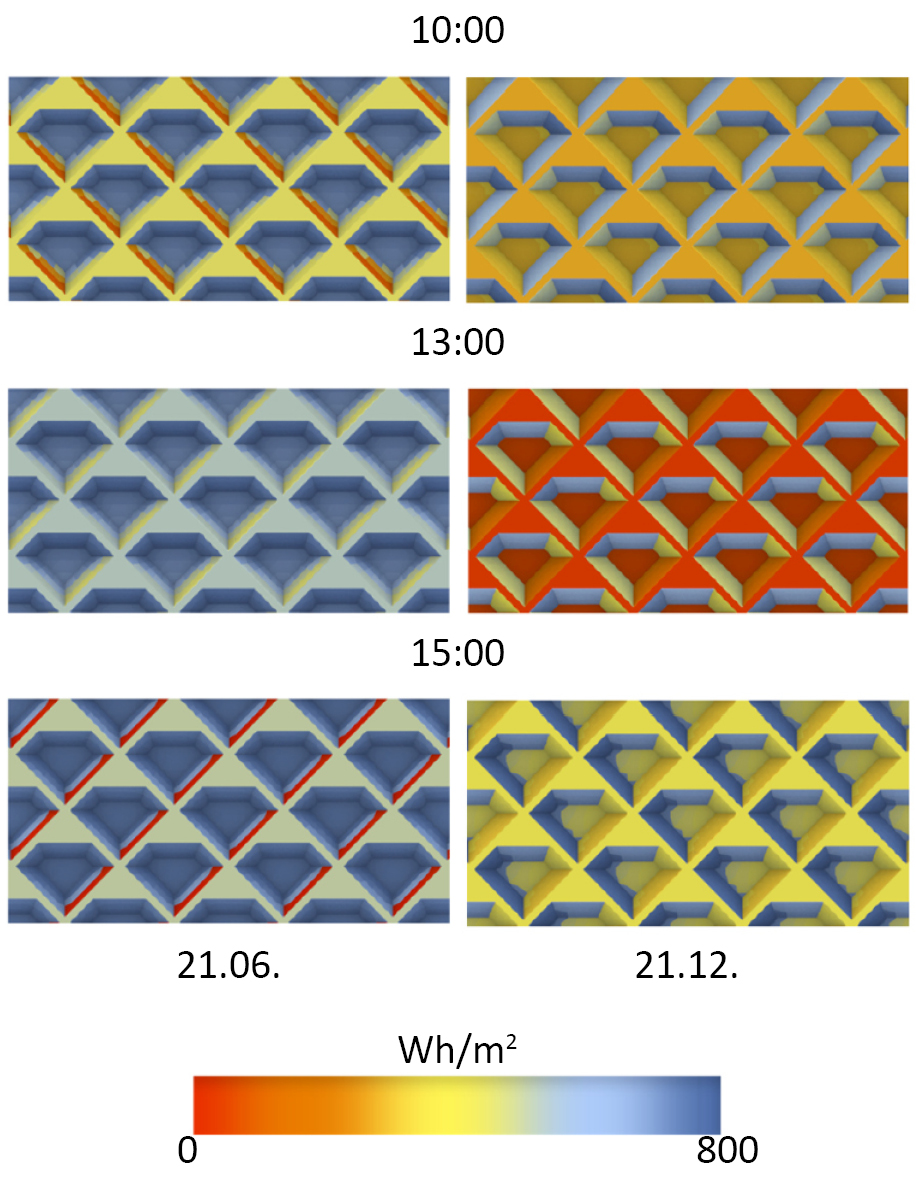

A team from A10, C01, and C03, along with Prof. Nagler, is exploring prefabricated SPI blocks with lightweight aggregates for low carbon emissions. The design merges structural performance, insulation, thermal mass, and load-shifting. Investigations include radiation analysis of a parametrically designed façade and heat flux simulations, leading to a building design and a fabricated demonstrator showcasing the integrated features.

Acoustic Optimization with AMC

PhD researcher Ahmad Saleem Nouman has been integrating parametric designing with acoustic simulation tools to study the effects of AMC on acoustic comfort in indoor environments. The simulation results indicate that room acoustics can be optimized by leveraging AMC’s design possibilities. Additionally, the unique textures produced by each printing technique and their wide range of material mixtures have significant potential to enhance indoor acoustics (Figure 3). Consequently, an acoustic design and an acoustic material study are being conducted by C03, involving printing, extracting, and laboratory testing of AMC materials with research groups A01, A02, and A04.

This study will also help reduce material usage by taking advantage of the properties of printed materials, potentially eliminating the need for additional equipment, such as sound absorbers in rooms. Ultimately, this will improve environmental performance through AMC, leading to more sustainable and efficient building designs. The knowledge attained from this study will also enable the utilization of different printing techniques and their vast range of materials for their individual acoustic qualities. This will facilitate the setup of future AMC buildings to effectively resolve potential acoustic problems through specific printing techniques and material selection.

Fig 1: Earth 3D printed TOVA Demonstrator (©IAAC), where C03 is setting up a monitoring for its climatic behaviour and an experimental evaluation of passive cavity ventilation. / Credit: AMC-C03; David Briels

Fig 2: Radiation Analysis on a solar-responsively designed AM-façade of BloXMurocaust. / Credit: AMC-C03; David Briels, Katharina Schröder

Fig 3: Sound propagation and visual analysis of the impact of ceiling material and design on the acoustic quality of an office room, observed at different time intervals. / Credit: AMC-C03; Ahmad Saleem Nouman