Research Summary Report of C03

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

[11.04.2025]

M. Sc. Ahmad Nouman Researcher, ahmad.nouman@tum.de

M. Sc. David Briels Researcher, david.briels@tum.de

Prof. Dr.-Ing. Thomas Auer Project leader, thomas.auer@tum.de

Technical University of Munich, TUM School of Engineering and Design, Chair of Building Technology and Climate Responsive Design

Project C03 explores how Additive Manufacturing (AM) can create advanced building components that integrate both passive (e.g., thermal resistance, acoustics) and active functions (e.g., ventilation, thermal activation). We leverage AM’s ability to produce complex, material- and geometry-specific elements to enhance building performance, reduce carbon emissions, and improve indoor environmental quality.

We use parametric, simulation-based, and performance-driven design methods to develop climate-responsive, fabrication-aware solutions. Our initial work involves modelling and testing individual functions – like thermal efficiency, air channels, and integrated heating – through small- and large-scale prototypes.

Further, we target hybridising multiple functions into scalable, practical design strategies in the current period, culminating in full-scale (1:1) demonstrators to validate manufacturing feasibility and performance. The overarching goal is simplifying and improving building design and operation through AM-enabled functional integration.

Current state of research

How to Print a House

Together with the Professorship of Digital Fabrication, we ran a design project for Master´s architectural students to further bring research topics from within the AMC into teaching and experimentally showcase the potentials of AM and its implications for design. The design task was based on SPI, focusing on using its features (resolution and granularity, building physics, geometric freedom, etc.) as a design driver for climate-responsive and robust building design, referring also to the principles of Einfach Bauen. The results revealed fascinating design strategies, particularly for monolithic façade elements. For example, as Figure 1 illustrates, these designs combine and hybridise functions such as thermal insulation with internal cell structures, adapted explicitly for compression-dominant load transfer and incorporate integrated solar shading overhangs.

Experimental evaluation of acoustical performance of AM processes and materials

In collaboration with the Professorship for Vibro-acoustics of Vehicles and Machines at TUM, we assessed 86 material samples prepared by AMC groups A01, A02, A03, A04, C02, and B05. We used a 4-microphone, 2-load (4M2L) impedance tube system to evaluate their acoustic performance. The sample set included 18 samples from Extrusion 3D Printing (E3DP), which consisted of concrete and clay materials, 22 samples from Selective Cement Activation (SCA), 20 samples from Shotcrete 3D Printing (SC3DP), 11 samples from Selective Paste Intrusion (SPI), and 15 cast-concrete samples designed to mimic E3DP patterns.

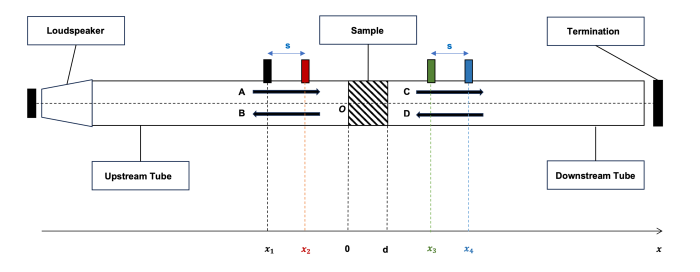

The testing method involved generating sound waves within the frequency range of 50 to 2000 Hz. We captured incident, reflected, and transmitted pressures using microphones positioned in the upstream and downstream sections of the tube. A sound card, amplifier, and acoustic software facilitated accurate sound absorption and transmission loss analysis for each material type.

We calibrated the microphones before each testing session. We also conducted channel correction to eliminate phase, amplitude, and channel gain variations. We also adjusted the impedance tube geometry and microphone spacing based on the targeted frequency range. Furthermore, we tested with reference specimens to validate the system’s accuracy before measuring the samples. The experiment allowed us to compare the acoustic behaviour across different AM processes and materials, supporting further analysis of how AM methods influence acoustic performance and how these properties could be used in various contexts and further optimised by new designs possible with AM.