Research Summary Report of C02

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Piecest

[28.10.2025]

Jakobs, Philipp; Researcher, philipp.jakobs@tum.de

Wüchner, Roland; Project leader, wuechner@tum.de

TUM, Chair of Structural Analysis

Main Goal

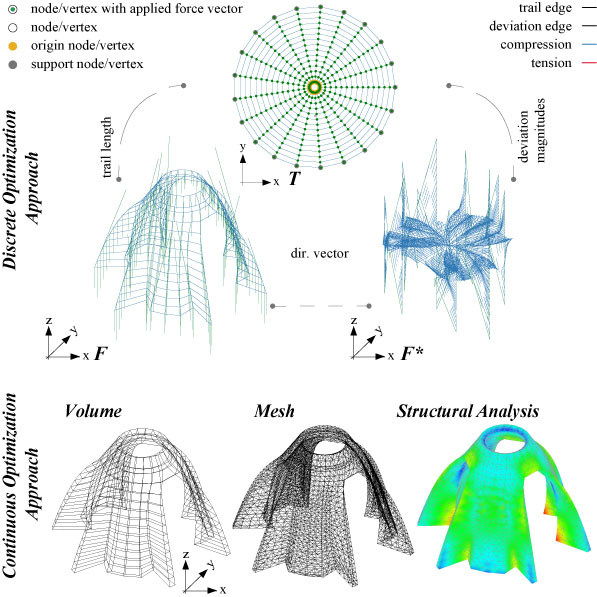

Current building practices often adopt a sequential design approach, where architectural, structural, and fabrication aspects are addressed independently, resulting in excessive material consumption. The CO2 project aims to establish a Holistic Design Framework (HDF) integrating the above-mentioned aspects. Within this framework, additive manufacturing facilitates structural optimization by enabling the production of bespoke geometries for an effective use of material resources. Departing from the conventional sequential approach, the HDF concurrently integrates low-fidelity Discrete Optimization Approaches and high-fidelity Continuum-based Optimization Approaches (multi-fidelity). The HDF tackles a range of additive manufacturing processes by operating across different scales (multi-scale) and accommodating diverse materials (multi-material).

Summary

The CO2 project “3D Structural Puzzle” continues to move toward its vision of a Holistic Design Framework for Additive Manufacturing in Construction. This framework combines digital design and structural optimization methods to make construction more resource-efficient and sustainable.

A major milestone has been achieved as the two core approaches, the Discrete Optimization Approach (DOA) and the Continuum-based Optimization Approach (COA), are now seamlessly linked within a unified workflow (Fig. 1). This connection allows low-fidelity design models developed with the DOA to be evaluated with a detailed, high-resolution analysis model. Selected solutions can then further be iterated in the COA with FEM-based Structural Optimization techniques.

Within the workflow, discrete strut and tie models generated by the DOA are converted into volumetric representations and meshed, enabling the transfer of boundary conditions and loading scenarios into a format compatible with the COA. These volumetric models can then be evaluated in high-fidelity FEM simulations, supporting the analysis of objective functions such as maximum tensile stress, strain energy, and mass. This integration forms a robust bridge between design exploration and detailed structural optimization, advancing the application of additive manufacturing in construction.

Parallel to this integration, the research on material grading optimization has been pushed forward in the Continuum-based Optimization Approach, allowing the representation of smooth material transitions and multi-material design strategies. Material gradation can be achieved, for example, by varying mix ratios or using multi-material extrusion in concrete 3D printing, as well as through lattice structures with variable strut thickness in metal printing.

In collaboration with projects A01, A02, A06, A07, A09, and A10, additive manufacturing-specific constraints such as printable dimensions, anisotropic material behavior, and process-dependent limitations have been identified and formalized. The resulting functions are implemented in a generalized way, ensuring compatibility across different demonstrators and scales within the AMC framework.

Ongoing work investigates both the connection between discrete and continuum optimization methods and the implementation of material grading optimization within the Holistic Design Framework. These developments have been explored and tested using an arching bridge structure.

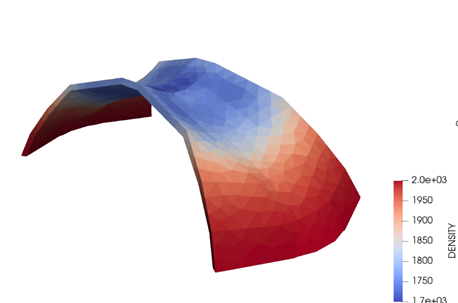

In this study, several bridge configurations were first generated through form-finding methods based on the Discrete Optimisation Approach and subsequently evaluated using high-fidelity continuum analyses. The continuum model allows the assessment of the different design variants with respect to load-bearing performance, stress distribution, and material efficiency under self-weight loading. Based on these evaluations, one representative design was selected for further investigation through material grading optimization (see Fig. 2).

The material grading optimization of the bridge is realized through a phase field formulation implemented in Kratos Multiphysics, where the material properties themselves serve as design variables. This allows smooth transitions in stiffness and density throughout the geometry. To ensure well-behaved solutions and to control the rate of gradation, vertex morphing filtering is applied as a regularization technique.

Together, these developments demonstrate how linking discrete and continuum optimization strategies with advanced material grading methods enables the design of lightweight and efficient structures optimized for additive manufacturing.