Research Summary Report of B06

Material modelling and simulation of deposition additive manufacturing processes on a part scale

[18.09.2025]

La, Quoc Tuan; Doctoral Researcher,quoc-tuan.la@tu-braunschweig.de

Jänicke, Ralf; Project Leader, r.janicke@tu-braunschweig.de

Kollmannsberger, Stefan; Project Leader, stefan.kollmannsberger@uni-weimar.de

TU Braunschweig, IAM and Bauhaus-Universität Weimar, IBMB

Main Goal

The main objective of this project is to predict structural failures in Shotcrete 3D Printing (SC3DP), a process in which a concrete mix is deposited using pressurized air. To achieve this, a viscoplastic material model is developed. The Finite Cell Method is employed to accurately capture complex geometries, while Variationally Consistent Computational Homogenization is applied to reduce computational costs. This combination enables faster simulations and supports more efficient design iterations.

Summary

In Shotcrete 3D Printing (SC3DP), the concrete mix is initially soft to allow deposition and gradually hardens over time to achieve its structural purpose. When subjected to loads exceeding its yield strength, the material transitions to a fluid-like state and exhibits pronounced viscoplastic behavior. Such characteristics are typically modeled using a combination of thixotropy and Bingham-type rheology.

Once the material model is developed and implemented in a Finite Element Method framework, it is calibrated against experimental data obtained from freshly printed SC3DP concrete. These tests include triaxial and indentation tests, which characterize the elastic and plastic material properties. Furthermore, tilting tests are performed to investigate the interactions between printed layers.

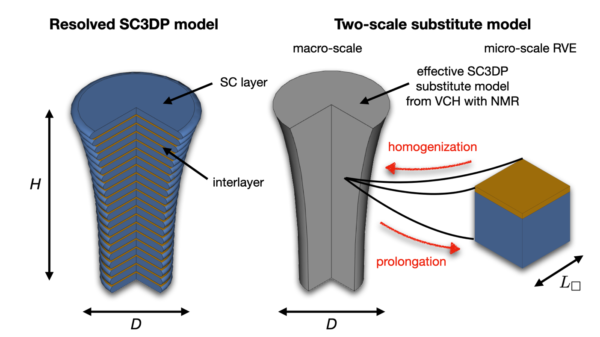

To simulate complex geometries using a high-fidelity material model, Variationally Consistent Computational Homogenization is combined with an advanced Finite Cell discretization strategy to allow for the integration of complex geometries. First, a Representative Volume Element is created to act as a constitutive driver for the macroscopic Boundary Value Problem, which is solved using the nested FE2 method. However, this procedure is computationally expensive and typically suitable for academic problems. To improve efficiency, Numerical Model Reduction is employed. This method collects snapshots during an offline phase using Proper Orthogonal Decomposition, allowing the macroscopic problem to be solved more efficiently during the online phase. Finally, the Finite Cell Method is utilized to create Finite Element models with complex geometries on a part scale.

The resulting macroscopic models are validated against SC3DP structures with unique geometries, such as double-curved walls and vaulted ceilings.

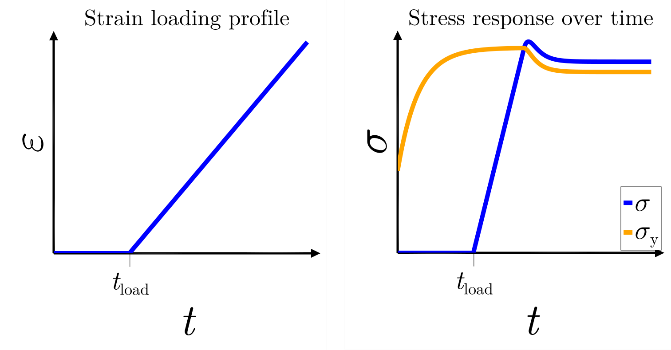

A viscoplastic material model with time-dependent yield strength has been developed. The behavior of the material used in SC3DP is visualized in Figure 2. With no load applied, the yield stress of the material increases to its maximum value. Once a load is applied at , a linear elastic response develops until the material begins to yield. Thereafter, the yield stress decreases.

To study the influence of material parameters and printing process parameters, the material model is implemented in the open-source Finite Element framework Ferrite.jl. Furthermore, the interaction between the layers is considered, accounting for the bonding strength of the layers and the time-dependent strength development of the concrete mix.