Research Summary Report of B04

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial – Robots with an Extended Degree of Freedom

[07.11.2025]

Akica, Ilknur; Researcher, i.akica@tu-braunschweig.de

Hürkamp, André; Project leader, a.huerkamp@tu-braunschweig.de

TU Braunschweig, Institute of Machine Tools and Production Technology (IWF)

Main Goal

The integration of robot-guided additive manufacturing in the construction industry increases the degree of automation and can thus lead to an increased productivity and increased component quality. In shotcrete 3D printing (SC3DP), reproducible manufacturing results and ensuring component quality are major challenges, as the properties of shotcrete depend on many different parameters (e.g. temperature, pressure, water-cement ratio, hardening accelerator). The goal of this research project is to develop a reproducible, robot-guided shotcrete process based on multi-model adaptive path planning for the production of large, high-quality and complex components.

Summary

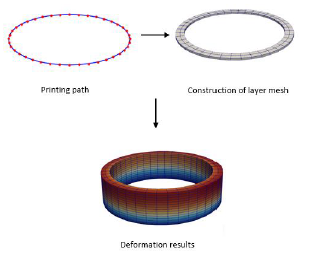

In order to achieve the target geometry during the printing process, it is essential to predict the behaviour of the printed structure and control its shape and stability by varying the mixture composition and process parameters such as nozzle speed, nozzle diameter, or the volume flow of concrete. The prediction is achieved using a built-in finite element code, which is designed to simulate the layer-by-layer printing process. The printing path of the machine is used to construct the 3D layer geometry. After each layer deposition, deformations are predicted, and subsequent layers are built on the deformed geometry to ensure a realistic simulation of SC3DP, as shown in Figure 1.

The finite element code allows the simulation of the time-dependent properties of fresh concrete by assigning timestamps to each element. Another important procedure is printing with different material mixtures, as this enables control of material properties to achieve the desired geometry or strength. However, using different mixtures during the printing process creates a so-called transition zone, where the material properties are a function of both the old and newly added materials. This is implemented by assigning a material ID to each element and calculating the material properties based on the element’s position.

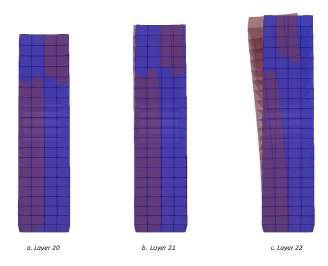

By optimizing the printing parameters and material properties, it is possible to achieve the desired geometry. However, it is often not possible to control the process itself precisely. Imperfections in the material mixture or process parameters can lead to the sudden failure of slender structures through buckling, as shown in Figure 2. Therefore, it is essential to identify the actual printing imperfections and study their effects on the printed structures.

The current research focuses on two main areas. First, the actual printing path and possible imperfections are being analysed, and the prediction of sudden buckling due to these imperfections will be implemented in the FEM code. In addition, the implementation of reduced-order models is being investigated to enable fast prediction of the deformation state of printed structures.