Research Summary Report of B03

Modelling and Simulation of Concrete 3D Printing Based on a Massively Parallel Multi-Phase, Multi-Component LBM Approach

[19.10.2025]

Kutscher, Konstantin; Researcher, kutscher@irmb.tu-bs.de

Geier, Markus; Project leader,geier@irmb.tu-bs.de

Krafczyk, Manfred; Project leader, kraft@irmb.tu-bs.de

TU Braunschweig, IRMB

Main Goal

The project is currently concerned with the simulation of a moving nozzle for the injection process using I3DCP. We are particularly interested in the influence of the movement of the nozzle on the printed strand.

Summary

In order to avoid costly remeshing of the moving nozzle in the simulation of Injection 3D Concrete Printing (I3DCP) the interior of the nozzle remains to be modeled as a fluid with the velocity of the solid body imposed on the interior nodes. In the initial implementation this was done by adjusting the velocity at the end of each time step. In the explicit setting of the applied lattice Boltzmann method this led to a small, yet significant leakage of flow into the solid which resulted in the concrete-phase slowly creeping into and through the nozzle. The forcing term has since been replaced by a time symmetric force that adjusts the velocity in the middle between two time steps. This led to a drastic reduction of the leakage and no more penetration of the concrete phase into the nozzle. Figure 1 shows a comparison between the two methods.

The software VirtualFluids, which is extended for the purposes of the AMC has been made open source and was published together with a formal paper in Geier et al. 2025. The code has been developed for internal use for the past 20 years. In order to facilitate its use by non-developing researcher, the code structure has been subaerially modified for concise nomenclature and ease of use. VirtualFluids offers massively parallel simulation of fluid flow problems on both CPU and GPU clusters. VirtualFluids is now available for external use inside and outside the AMC. Users of VirtualFluids and other interested researchers are encouraged to participate at the International Workshop on VirtualFluids, first held in Roskilde in 2025 and in Visby (Sweden) 26th-29th May 2026.

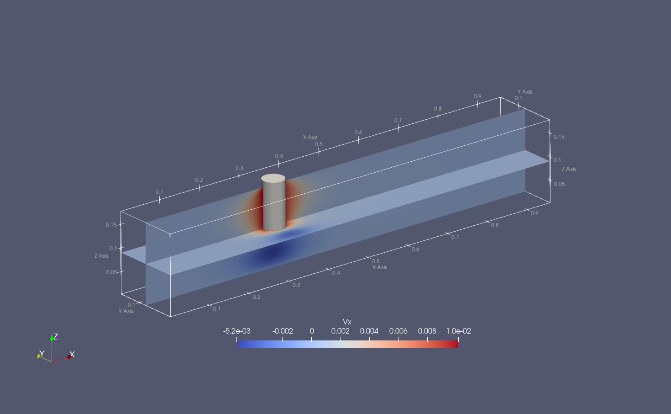

To assess the ability of our lattice Boltzmann solver to simulate the non-Newtonian behavior of the carrier liquid of the I3DCP process, the drag-rheometer developed by A09 is reproduced in the simulation and the forces computed are compared with the forces measured. In addition to the physical parameters of the applied Bingham model, i.e. plastic viscosity and yield stress, the numerical model has a cut-off viscosity as an additional numerical parameter. The reason for this is that below the yield stress the viscosity of the Bingham fluid would formally go to infinity which is infeasible in a time explicit numerical method as it would require infinitely small time steps. To mitigate this the infinite viscosity state is modeled by a large but finite viscosity. The simulation of the drag-rheometer has revealed that the acting forces are significantly influenced by this cut-off value for the viscosity such that significant effort has to be invested in the calibration of the model. Figure 2 shows the velocity field in the simulation of the drag rheometer.