Research Summary Report of A10

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

[31.10.2025]

Krakovská, Ema; Researcher, ema.krakovska@tum.de

Prof. Dr. Kathrin Dörfler; Project leader, doerfler@tum.de

Technical University of Munich, Professorship of Digital Fabrication

Main Goal

The primary research objective of A10 is to conceive and investigate two novel Earth Additive Manufacturing (EAM) processes, their material-process interactions, and their evaluation in large-scale architectural applications. Focusing on the characterisation of earth-based material mixtures (PL Machner), the project investigates a) Sprayed Earth Additive Manufacturing (SEAM) as a deposition-based process (PL Kloft) and b) Intrusion Earth Additive Manufacturing (IEAM) as a particle-bed-based process (PL Dörfler). The research aims to assess earth-based materials for these processes with a focus on pumpability, buildability, shrinkage, and strength. It seeks to develop the two processes with varied material combinations. Additionally, the research explores these technologies for architectural components combining insulation and load transfer, validated through full-scale fabrication experiments and demonstrators.

Summary

This report overviews ongoing research into the novel particle-bed fabrication technique with earthen materials titled Intrusion Earth Additive Manufacturing (IEAM). IEAM employs a robotically extruded earth paste consisting of clay, sand, straw fibres, and water, to act as the binder in an aggregate bed composed of recycled bricks. The earth binder is applied directly on the aggregate bed and followed by a uniform layer of aggregates. The aggregate is pressed into the binder using a stamping tool before the next layer is applied. The method is being developed concurrently from three perspectives: material, process, and application, embedded in the interdisciplinary research framework of PL Dörfler with PL Machner and PL Kloft.

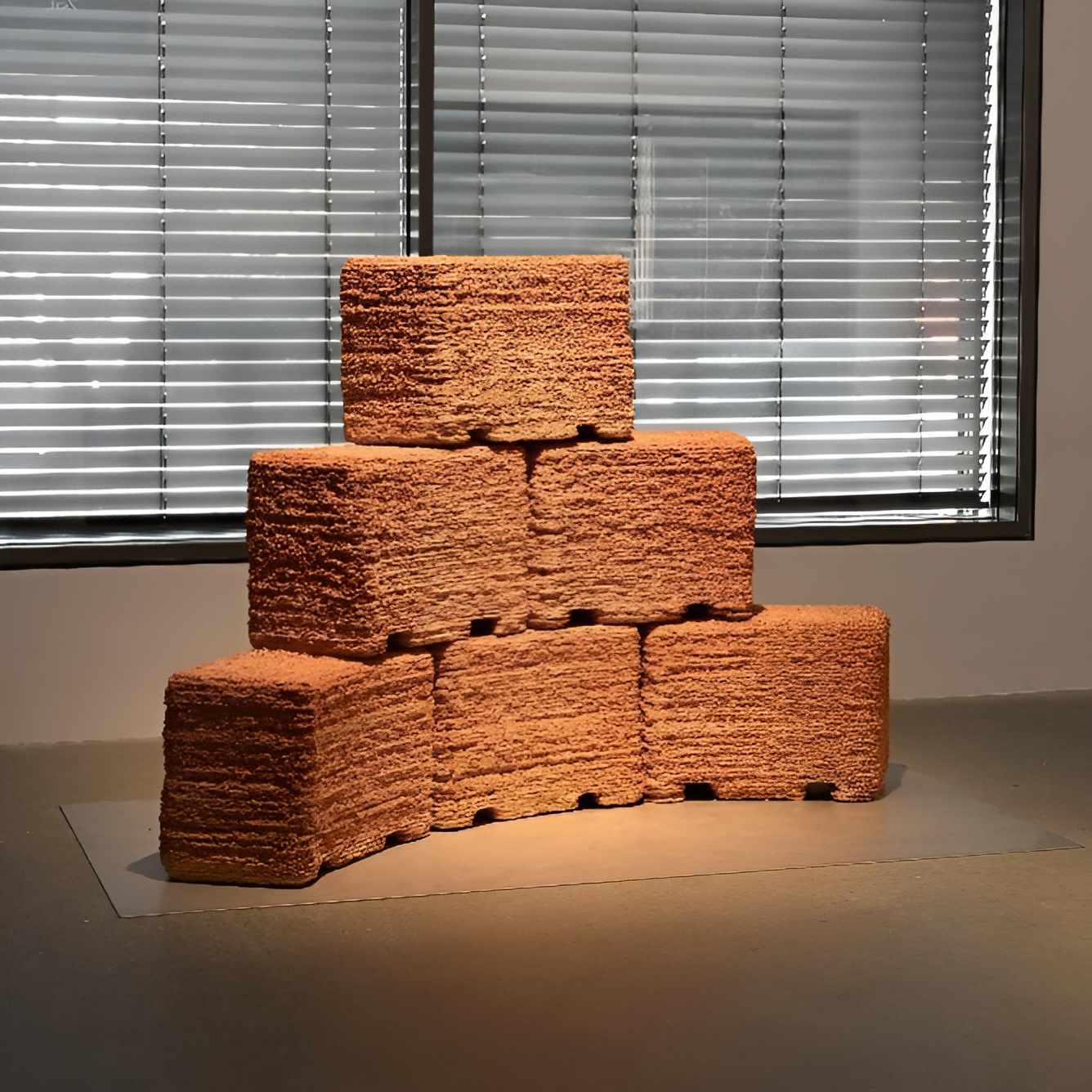

Currently, the robotic fabrication setup for IEAM has been further developed, resulting in the full automation of all processing steps, as well as the integration of an aggregate storage and conveying system to support continuous operation. The setup enabled the fabrication of the largest IEAM prototype to date: a six-component assembly that forms a curved wall section. The prototype was presented at the City in the Cloud: Data on the Ground exhibition in Munich, where it served as a demonstrator for the prefabrication of free-form, load-bearing building elements using earth-based materials (Fig. 1).

Alongside the system development and prototype fabrication, a series of initial material investigations was conducted. These studies examined the behaviour of various earth-binder compositions and aggregate grain size distributions and explored the relationship between binder and aggregate layer heights. These experiments provide a foundational understanding that supports further refinement of the IEAM process.

Each component measured roughly 40 cm in width, 80 cm in length, and 50 cm in height, and together they formed a segment of a circular wall. Fabrication was completed in two print jobs, each producing three components. After printing, the particle bed was carefully deconstructed, and the surrounding unbound aggregates were vacuumed back into the storage silo for reuse in later prints. Once extracted, the components were left to dry for 28 days before being transported to the exhibition space for assembly.