Research Summary Report of A07

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

[04.07.2025]

M. Sc. Marc Müggenburg Researcher, marc.mueggenburg@tu-braunschweig.de

Dr.-Ing. Julian Unglaub Project leader, j.unglaub@tu-braunschweig.de

Technical University of Braunschweig, Institute of Steel Structures

A07 focuses on developing load-specific, individual high-strength low-alloy steel DED-Arc components, understanding strengthening solutions for existing structures and designing various manufacturing strategies. The specific challenges of adaptive design and adaptive manufacturing of different scale components will be addressed and a digital twin including data from the design and manufacturing process, surface geometry and component performance will be elaborated. Physical and virtual component tests will be carried out to gain comprehensive knowledge on load-carrying capacity and ductility, buckling behaviour, the effect of imperfections and on fatigue performance. The project aims to advance DED-Arc application in construction by enhancing structural performance, improving efficiency while reducing material usage.

Summary

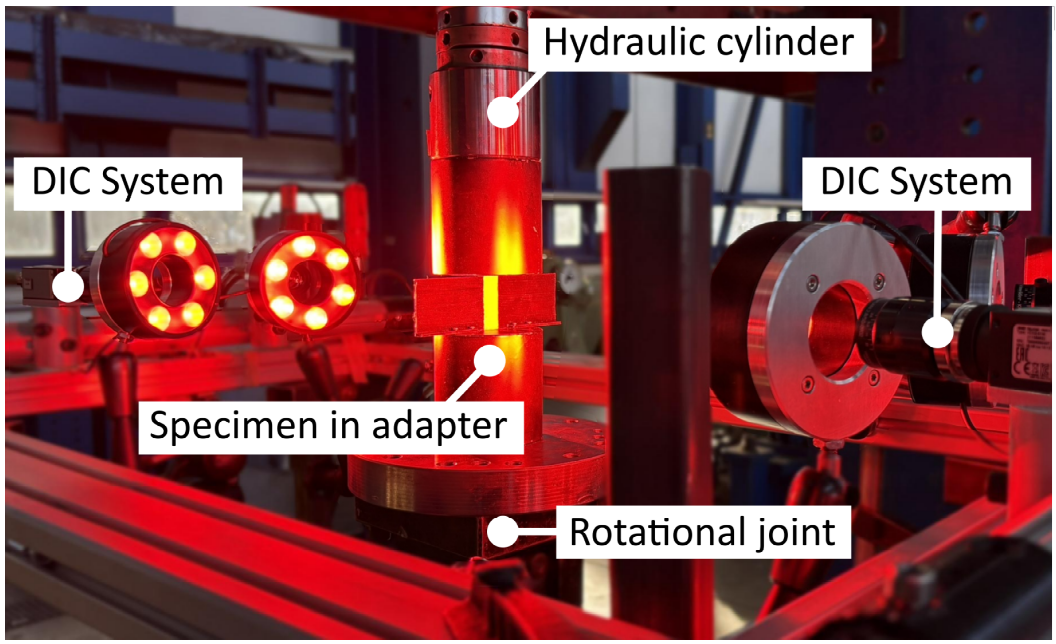

Working group (WG) Unglaub is currently investigating the load-carrying behaviour under cyclic loading of high-strength low-alloy steel DED-Arc components, which were manufactured by WG Hensel. Particular focus is placed on the influence of the as-built surface, resulting from the printing process, on the mechanical response. Therefore prior to testing, all specimens were 3D laser-scanned in collaboration with project C06 / WG Gerke to geometrically evaluate their surface topography. Then, uniaxial tensile fatigue tests were conducted using a servo-hydraulic testing machine in combination with a four-camera Digital Image Correlation (DIC) system (see Fig. 1), enabling high-resolution, non-contact measurement of surface displacement fields at selected load cycles.

The results indicate that the complex as-built surface geometry leads to localized strain concentrations at the layer boundaries. Specimens with reduced geometric variability exhibit higher fatigue strength, underlining the interdependence between printing process parameters, resulting surface geometry and component performance. The knowledge gained from the fatigue tests complements previous studies on quasi-static load-bearing behaviour in tensile and compressive tests and will be used to improve both the physical testing procedures and the virtual testing approaches within the project.

Current state of research

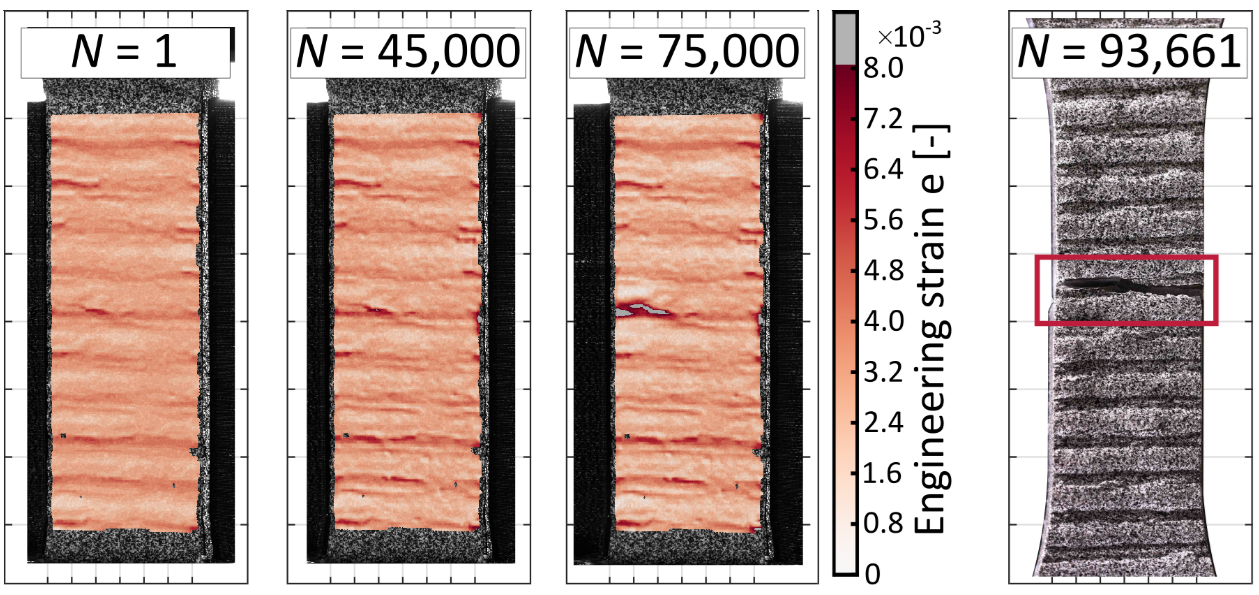

The strain fields resulting from the DIC evaluation of the displacements of the specimen’s surface in Fig. 2 reveals pronounced strain accumulation at layer boundaries, already during the first load cycle (N = 1), becoming increasingly distinct throughout further loading. At subsequent load cycles, large strain accumulation zones can be observed.

These localized strain zones can be used as an indicator of the region, where the fatigue fracture of the specimen will occur, see Fig. 2 (right). These results highlight, that understanding local effects is essential for the assessment of the overall structural performance of DED-Arc components.