Research Summary Report of A07

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

[23.08.2024]

Müggenburg, Marc; Doctoral Researcher, marc.mueggenburg@tu-braunschweig.de

Unglaub, Julian; Project Leader,j.unglaub@tu-braunschweig.de

Institute of Steel Structures Technische Universität Braunschweig

Main Goal

A07 focuses on understanding the interaction between DED-Arc (alias WAAM) components and existing structures, developing load-specific strengthening solutions and designing welding strategies. The specific challenges of adaptive design and adaptive manufacturing of large-scale high-strength steel DED-Arc components will be addressed and a digital twin including data from the design and manufacturing process, surface geometry and component performance will be elaborated. Physical and virtual component tests will be carried out to gain a comprehensive knowledge on buckling behavior, the effect of imperfections, load-carrying capacity and ductility. Overall, the project seeks to advance DED-Arc application in construction by improving efficiency, reducing material usage and enhancing structural performance.

Summary

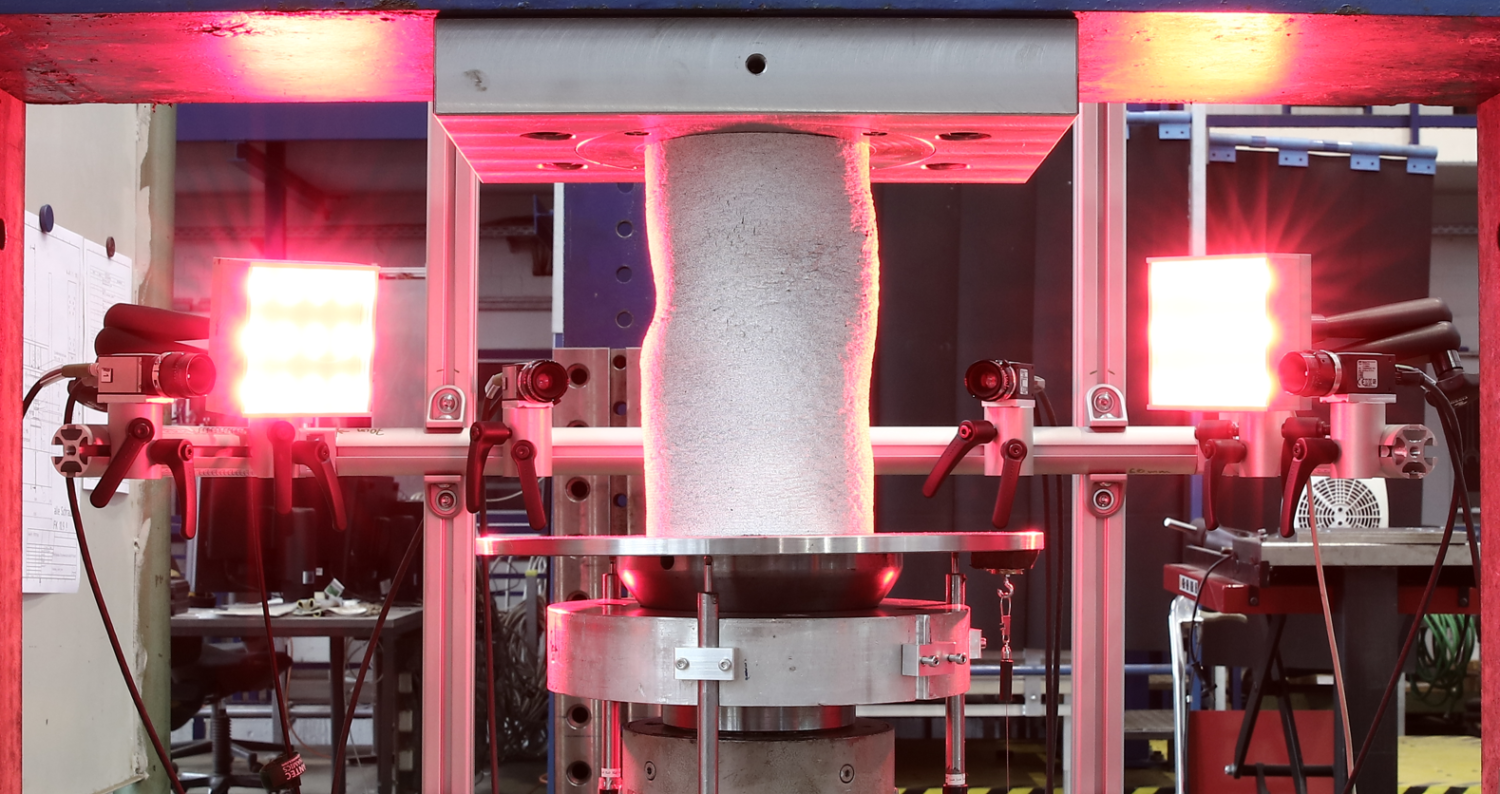

Working group (WG) Unglaub is currently investigating local buckling on component scale. For this, multiple geometrically modified cylinders made of high-strength steel have been manufactured by the WG Hensel while recording the printing process parameters. Subsequently, the “as-built” geometries of the stub columns were 3D laser-scanned in collaboration with Project C06 / WG Gerke to evaluate their geometric parameters. The stub columns displayed higher geometrical variation compared to dog-bone specimens from previous investigations. Local buckling tests were performed and the displacement fields were recorded with a four camera DIC system (see Fig. 1). The DED-Arc components displayed a pronounced buckling behavior indicating a high degree of ductility. The data from the geometrical evaluations as well as the results from mechanical testing were used to gain a better understanding of the effect of imperfections, load-carrying capacity and ductility on component response. Additional simulations have been performed to further evaluate the buckling behavior. This knowledge will be used for printing and testing future components as well as demonstrators.

Current state of research

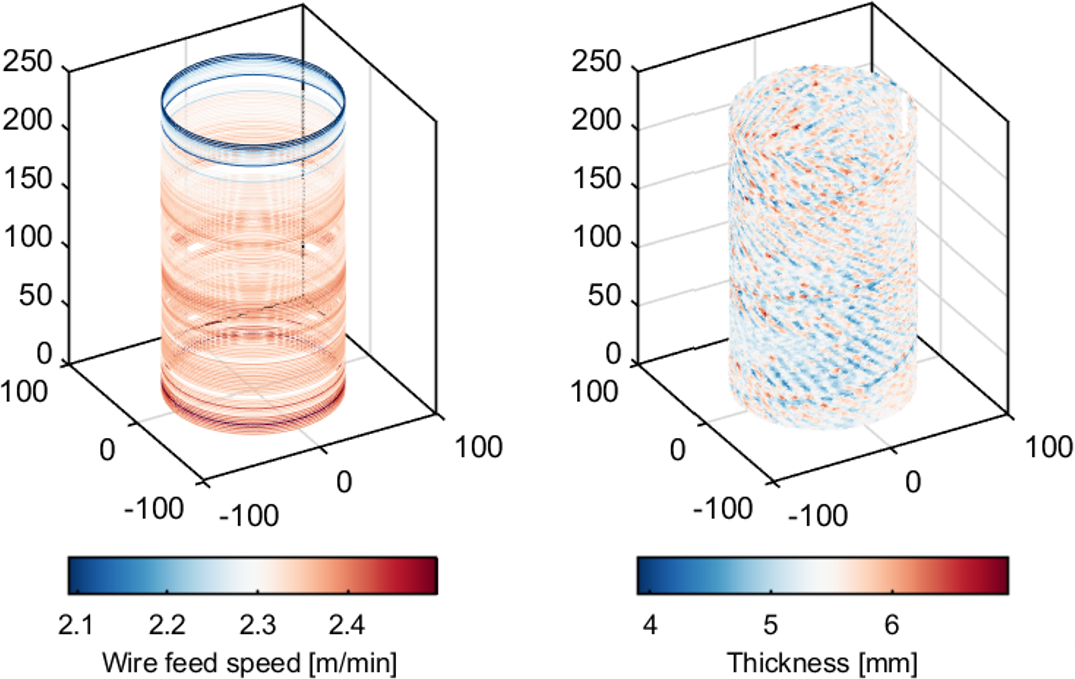

In order to combine data from manufacturing and from geometrical analysis a digital shadow has been employed based on the as-designed geometry of the stub columns, exemplary shown in Fig. 2.

Based on results of uniaxial quasi-static tensile test of dog-bone specimens with as-built surface, a two-stage Ramberg-Osgood material model was developed. The material model was used for a geometrically and mechanically nonlinear analysis with imperfections (GMNIA) of the local buckling of the stub columns. Good agreement with the load-displacement behavior as well with as the out-of-plane deformations has been achieved. The high geometric variability of the as-built surface has been identified to have the largest impact on component behavior for DED-Arc stub columns.

Fig. 1: Test setup with four camera DIC system and local buckling of stub column in a compression test / Credit: Marc Müggenburg

Fig. 2: Manufacturing and geometric data combined in a digital shadow of the stub columns / Credit: Marc Müggenburg

100x speed video of a compression test with local buckling of a DED-Arc stub column (Test Setup depicted in Fig. 1 in the RSR)