Research Summary Report of A06

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience

[19.03.2024]

Blankenhagen, Jakob; doctoral researcher; Jakob.blankenhagen@tum.de

Technical University of Munich, Chair of Metal Structures

Wenzler, David; doctoral researcher; david.wenzler@tum.de

Technical University of Munich, Institute for Machine Tools and Industrial Management

Summary

The project A06 aims to develop a methodology for producing safe and functional structural steel elements for construction using LPBF. This involves integrating complex LPBF parts into large-scale structures. For this purpose, the focus is laid on transferring results and qualification methods from the first funding period to new materials, such as Printdur HSA®. This steel material has been developed specifically for LPBF. And offers higher strength and a lower carbon footprint than 316L, the material from the first funding period. In work package 2, a methodology will be derived, predicting fatigue behavior based on process monitoring data and machine learning. Work package 3 integrates functions into parts using lattice structures for tailored stiffness. work package 4 investigates joining LPBF-manufactured steel with conventional construction steel for global structural behavior assessment. The final work package 5 aims to collect data for a reliable life cycle assessment of LPBF construction parts.

Current state of research

Project A06 already investigated the influence of surface roughness on the fatigue life of LPBF parts. The as-built state of the specimens have been compared with those that underwent manual polishing and vibratory grinding. Additionally, the impact of hot isostatic pressing (HIP) was examined. This is especially interesting since the HIP process aims to close pores by applying high atmospheric pressure during heat treatment.

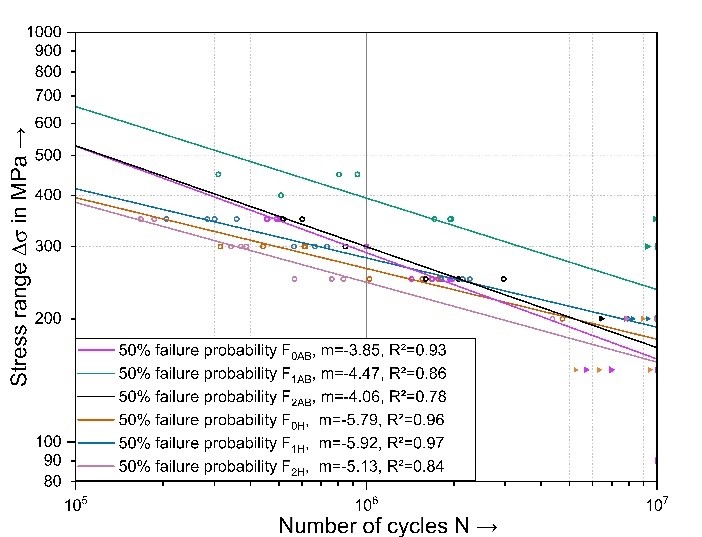

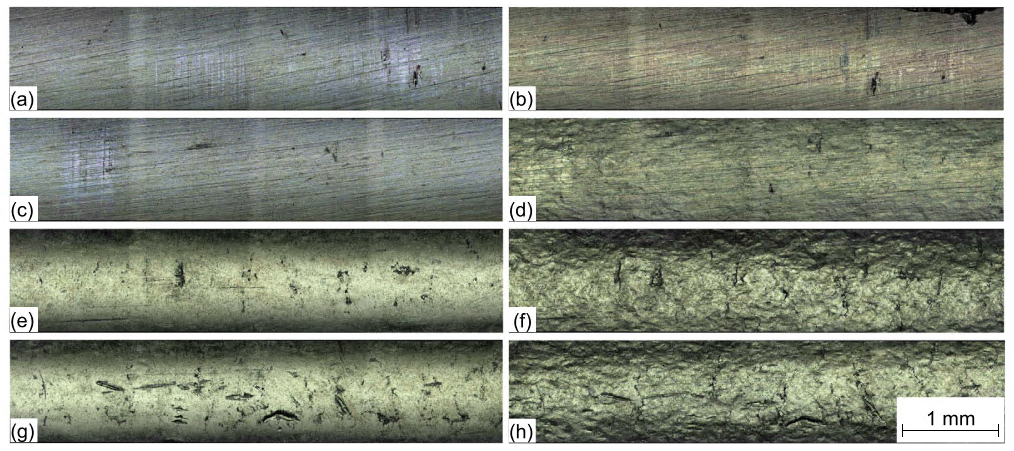

Fig. 1 shows the results of respective fatigue tests. The depicted SN-curves indicate that the surface roughness and the heat treatment influence the fatigue life. The impact of various factors on fatigue resistance can be hierarchically established as follows: Grain size exerts the most significant influence, followed by surface roughness and residual surface stresses. The vibratory grinding (F2AB and F2H) diminished the fatigue resistance by opening surface near pores. On the other hand, manual polishing (F1AB and F1H) closed pores near the surface and introduced compressive residual stresses, thereby enhancing fatigue resistance. The surface topology of the hot isostatically pressed, and vibratory ground specimens changed rapidly after a few loading cycles, in contrast to as-built specimens subjected to the same surface treatment. This can be seen in Fig. 2.

Fig 1: Results of fatigue tests in the as-built, heat-treated state, and with different surface treatment states. A stress ratio of 𝑅 = 0.1 was applied. 𝑚 represents the slope of the different regression lines, 𝑅2 represents the coefficient of determination. The triangles indicate the runouts [1]

Fig. 2: Surface topology before fatigue testing and after fatigue failure; 𝐹1 (manually polished) at 200 MPa stress range before (a) and after (b) fatigue testing, 𝐹1 (manually polished) at 300 MPa stress range before (c) and after (d) testing, 𝐹2 (vibratory ground) at 200 MPa stress range before (e) and after (f) testing, 𝐹2 (vibratory ground) at 300 MPa stress range before (g) and after (h) testing [1]