Research Summary Report of A04

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

[30.08.2024]

David, Martin; Doctoral Researcher, m.david@tu-braunschweig.de

TU Braunschweig, Institute for Machine Tools and Production Technology (IWF)

Main Goal

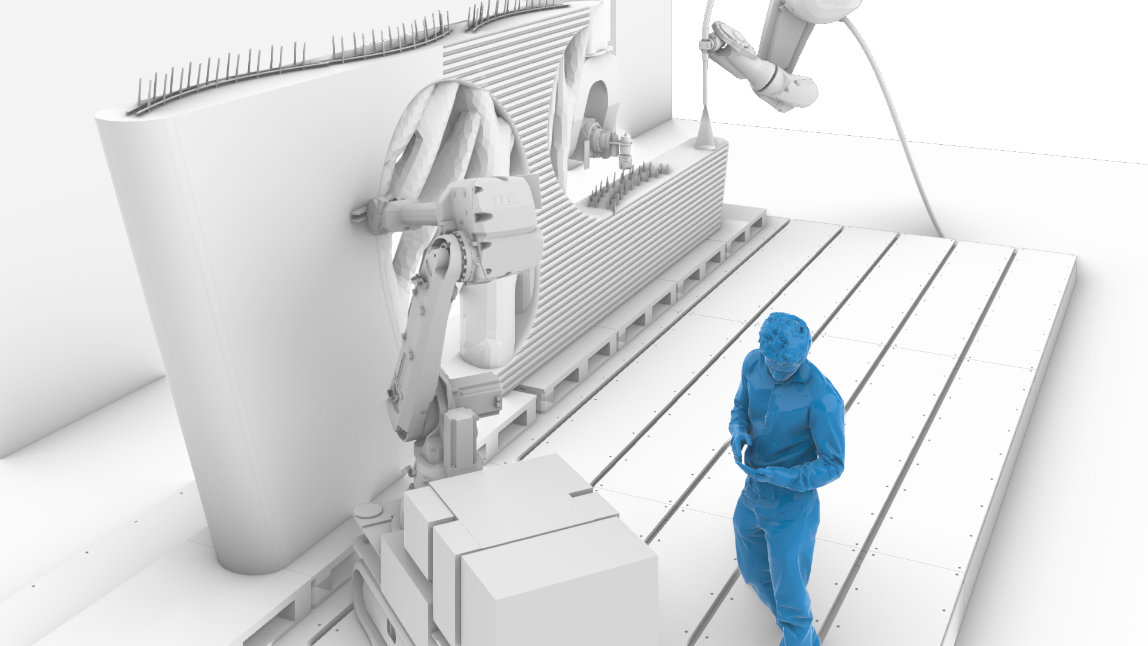

Project A04 aims to investigate cooperative Additive Manufacturing (AM) processes based on Shotcrete 3D Printing (SC3DP) for the production of material-efficient, force-optimised, reinforced, load-bearing concrete components with precise surface quality and geometrical precision. The goal is to produce large-scale concrete elements using significantly less reinforcement and concrete compared to standard concrete construction principles. Hereby, different robot guided end effectors are subject to research in a flexible and automated process chain.

Currently, the following key points are researched:

- Development of end effectors for the processing of free-from concrete surfaces

- Implementation and transfer of SC3DP and reinforcement integration to mobile robots

Summary

The aim of A04 in the 2nd funding period is the reduction of the carbon footprint of reinforced 3D printed concrete elements with complex shapes and free-form surfaces. By means of the SC3DP printing process, this leads to a change in material (e.g. reduction of cement content by an increase of aggregate size, use of different binders). From an automation standpoint this results in adapting the printing setup, as an increased aggregate size leads to larger nozzle diameter sizes, which changes the material properties of the strand [1] and the properties of the building component [2]. Apart from changes in the nozzle design, more complex path planning strategies will be investigated and tested. More complex path planning leads complex parts, which leads to more advanced reinforcement strategies and surface finishing processes.

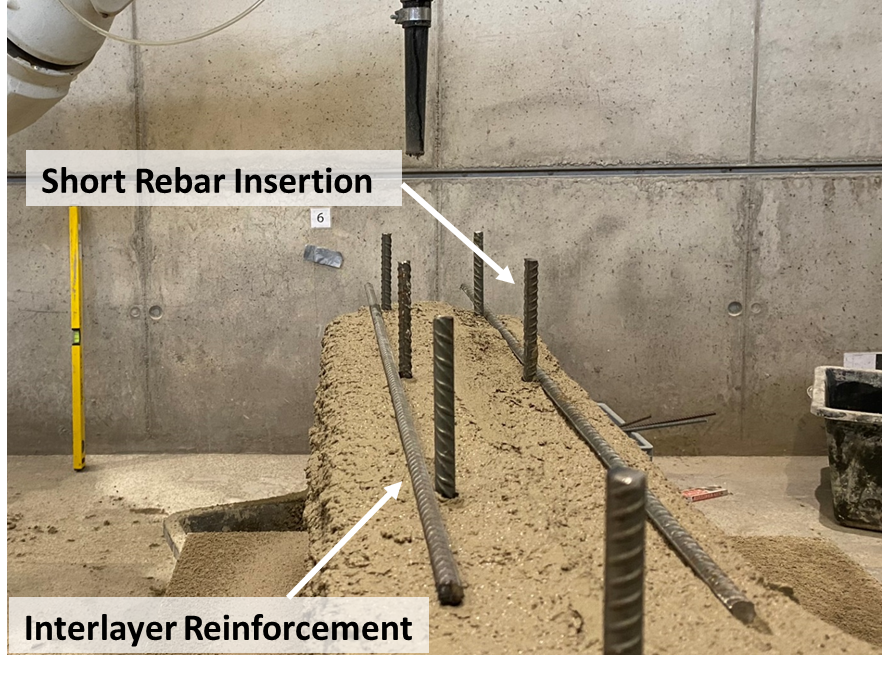

Processes for building complex reinforcement shapes have to be investigated, as more complex load bearing structures need complex reinforcement arrangements. Therefore, different approaches such as joining prebend rebars to complex rebar shapes or combining different reinforcement processes, such as Short Rebar Insertion (SRI) and Interlayer reinforcement (ILR) have to be investigated. For both approaches, precise handling and positioning strategies for rebars have to be established.

For free-form surface finishing, new processes have to be investigated, as processes and tools of the state of the art, such as trowels and rotating discs, lack in form flexibility to process curved surfaces efficiently. Here, new concepts and automated tools, like form variable trowels or inflatable and rotating discs have to be developed.

Current state of research

The main challenges in the manufacturing of complex reinforcement processes involve the handling of prebend rebars as well as processes for connecting and assembling complex rebar structures. Especially processes like stud welding, arc welding, soldering and clamping have to be evaluated regarding their feasibility (heat development, forces on the surrounding concrete, automation potential) and potential to be combined with other reinforcement types and methods like single fibers or fiber mats.

For free-from surface finishing, the timing of processing (parallel to printing or in a post-process with a 2nd layer) might be a crucial factor for the surface quality. Further, the investigation of process, tools and control strategies for double curved surfaces will be advanced in the future.

And finally, research regarding the transfer of these processes to on-site production on stationary or mobile machines will to be conducted. Compensation and control strategies will be investigated for the already developed processes, like SRI. Further, a special focus will be put on surface finishing processes with mobile robots.

References:

[1] Freund, N.; David, M.; Böhler, D.; Mai, I.; Ullmann, S.; Dröder, K.; Lowke, D. (2023): Shotcrete 3D Printing – Interaction of nozzle geometry, homogeneity and hardened concrete properties, Proceedings ‘Internationale Baustofftagung ibausil’, Weimar, Germany. https://doi.org/10.1002/cepa.2818

[2] David, M.; Freund, N.; Dröder, K.; Lowke, D. (2023): The Effects of Nozzle Diameter and Length on the Resulting Strand Properties for Shotcrete 3D Printing, Springer Materials and Structures. Pre-Print: https://doi.org/10.21203/rs.3.rs-3142213/v1