Research Summary Report of A04

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

[17.12.2025]

Dörrie, Robin; Researcher, r.doerrie@tu-braunschweig.de

Prof. Dr. Harald Kloft; Project leader, kloft@tu-braunschweig.de

Technische Universität Braunschweig; ITE Institute of Structural Design

Main Goal

The project aims to fundamentally understand the Shotcrete 3D Printing (SC3DP) technology to manufacture sustainable, multi-objective optimised, reinforced concrete components with precise surface quality and improved building physics via functional integration. It seeks to minimise the carbon footprint of 3D printed structures by exploring various material strategies, such as reducing cement content by increasing the aggregate size or replacing cement with a different binder and design methods to optimise the usage of concrete in order to decrease the overall concrete volume used. Additionally, it focuses on establishing a reliable material and process control, emphasising fresh material laws for printability and durability, real-time monitoring of concrete properties, and component build-up strategies.

By the end of 2025, the second year of funding Phase 2, three milestones in Project A04 are envisioned. Currently, WG Kloft is working on reducing material usage through topology optimisation for SC3DP elements, developing adjustable printing strategies for graded elements, and integrating precise surface finishing and reinforcement.

Within Work Package 1, WG Kloft investigated the potential for utilising topology optimisation with process constraints encoded. By combining the results of preliminary work outlining the geometric capabilities of the process with topology optimisation software, printable structures could be generated in an initial study. However, further exploration is needed to determine the most suitable type of element for achieving high material efficiency through the optimisation process. Furthermore, architectural quality must be considered when topology optimisation involves removing functions such as closing off spaces or insulating capacities.

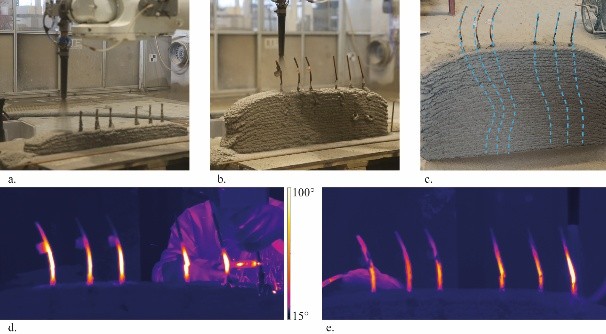

In the scope of work package 2, WG Kloft is exploring graded printing in close collaboration with WG Dröder and WG Lowke. Initial tests using a mixing nozzle and a double nozzle setup showed potential for graded construction elements. Two types of concrete can be used in areas where structural demands require high or low mechanical performance. Furthermore, this can be combined with the structural optimisation process to reduce material consumption and increase utilisation of materials.

Reinforcement integration for 3D-printed objects is an ongoing research topic Experiments have been conducted in WP3 to test new joining methods for force-flow oriented reinforcements. Vertical reinforcement structures that extend beyond the layers must be continued while printing the structure. Therefore, two novel techniques utilising welding for joining have been tested. The results showed that these techniques can be used simultaneously with printing; however, a distinct printing strategy must be planned and the temperature of the welded spots must be closely monitored to ensure sufficient bonding around the rebar.